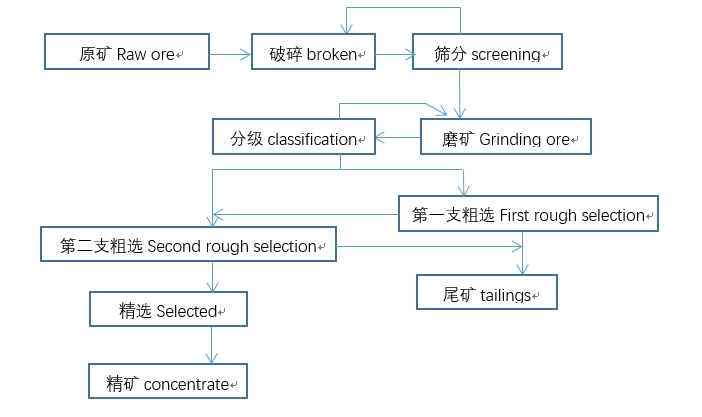

The branch serial flow flotation process of lead-zinc ore is a more complex flotation method. It divides the original pulp into two branches, carries out different flotation treatment, and then combines the previous rough foam with the latter raw pulp for rough separation, so as to realize the recovery of lead-zinc ore.

The Separation Flotation Process of Lead Zinc Ore

1.Raw slurry segmentation:Divide the original slurry into two branches, each with different properties and flotation conditions.

2.First rough selection:Roughly select the first raw slurry and separate the valuable minerals from the gangue minerals. This step is usually carried out by using a flotation machine. By adding appropriate flotation reagents, valuable minerals can float to form a foam layer.

3.Second rough selection:Roughly select the second raw slurry and also separate the valuable minerals from the gangue minerals. The flotation conditions in this step are usually different from the first one, in order to better recover different types of minerals.

4.Foam merger:Combine the foam obtained from the first roughing with the second raw pulp for roughing. This kind of merger can improve flotation efficiency and enable more valuable minerals to be recovered.

5.Selection and tailings treatment:The combined roughing foam is carefully selected to further separate valuable minerals and gangue minerals. The selected tailings need to be treated appropriately to meet environmental requirements.

Characteristics of Split Flow Flotation Process for Lead Zinc Ore

1.High sorting efficiency:By dividing the original slurry into two branches and performing different flotation treatments, valuable minerals and gangue minerals in lead zinc ore can be more effectively separated, improving sorting efficiency.

2.flexibility:The branch flow flotation process can flexibly adjust the flotation conditions according to the specific properties of the ore and the flotation properties of different minerals, in order to adapt to different ore types and mineral compositions.

3.Optimize drug use:Due to the fact that the branch flow flotation process can select suitable flotation reagents for different pulp properties of different branches, the use of reagents can be more optimized and costs can be reduced.

4.Improve recovery rate:The recovery rate of lead-zinc ore can be further improved by combining the foam of the former roughing and the original slurry of the latter roughing.

5.High resource utilization rate:The branch flow flotation process can more fully recover valuable minerals from lead zinc ore and improve resource utilization.

6.Environmentally friendly:Although the flotation process may produce some tailings and waste liquid, reasonable design and treatment can minimize the impact on the environment.

7.economic benefits:Through this method, the processing cost of ore can be reduced and economic benefits can be improved.

The branch flow flotation process of lead-zinc ore is an effective flotation method that can improve sorting indicators, reduce the number of selections, and save energy consumption. This method is suitable for various types of lead zinc ores and can be selected and adjusted according to the properties and characteristics of the ore.

Typical beneficiation plant

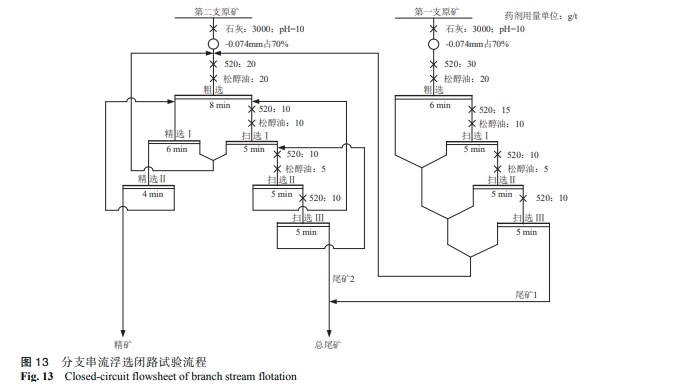

Yunnan Pu’er Dapingzhang Mineral Processing Plant: Adopting a branch serial flow flotation process, the first crude ore is mixed with the second raw ore to enter the second mineral processing process, sharing a set of selection equipment. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Gold Mine Heap Leaching: Optimal Process

- Arsenic Gold Ore Wet Chemical Pretreatment Process

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Lithium ore positive flotation process

- Radioactive beneficiation and flotation process for uranium ore

- Zirconium Ore Separation: Gravity and Magnetic Methods

- Effective Gravity Beneficiation for Chromium Ore

Leave a message with your needs or comments

Add comment: