The flotation process of quartz fluorite type ore is a mineral processing method specifically designed for the characteristics of this type of ore, mainly optimizing the separation effect of fluorite and quartz by adjusting the reagent system and grinding fineness.

Flotation process flow of quartz fluorite type ore

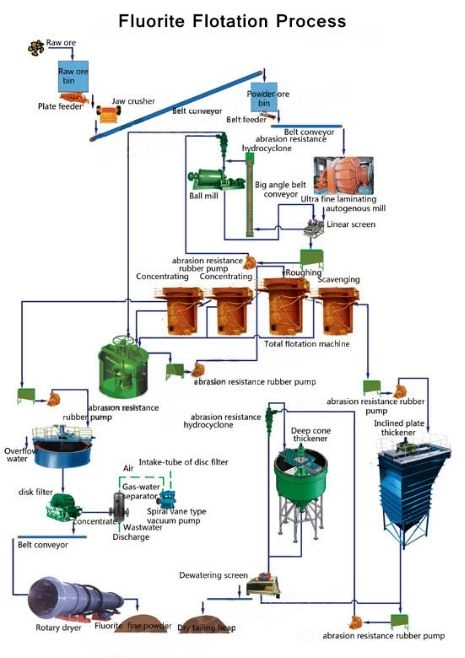

1.One grinding rough selection:Grind the raw ore once to achieve the appropriate fineness. Then perform flotation and adjust the pH of the slurry to alkaline using sodium carbonate to prevent the activation of quartz by multivalent cations. At the same time, fatty acid collectors are added to recover fluorite, and an appropriate amount of water glass is added as an inhibitor of quartz.

2.Rough concentrate regrinding and selection:The rough concentrate obtained from rough selection is regrinding to further improve mineral dissociation, in order to better separate fluorite and quartz. Then, multiple selections are carried out to gradually improve the quality of fluorite concentrate. During the selection process, it is necessary to strictly control the amount of sodium silicate to avoid its inhibitory effect on fluorite.

Technological advantages

1.Strong targeting:The flotation process of quartz fluorite type ore is designed based on the embedding characteristics of fluorite and quartz in the ore, which can effectively improve the recovery rate of target minerals and concentrate quality.

2.Medication system optimization:By using sodium carbonate to adjust the pH value of the slurry and sodium silicate as a quartz inhibitor, as well as fatty acid collectors, effective recovery of fluorite and effective inhibition of quartz have been achieved.

3.Flexible process design:For two types of ore, coarse-grained embedded and fine-grained embedded, the flotation process can be adjusted accordingly to adapt to different embedded characteristics of the ore.

4.Efficient separation effect :Through stage grinding and stage selection processes, especially for fine-grained embedded ores, the dissociation degree and recovery rate of the target minerals can be improved.

5.High resource utilization rate:Through multiple selections, useful minerals can be maximally recovered, resource utilization rate can be improved, and waste can be reduced.

6.Environmentally friendly:Compared with traditional flotation processes, this process reduces the use of chemical agents and has a smaller impact on the environment.

The flotation process of quartz fluorite type ore achieves effective recovery of fluorite and effective separation of quartz through precise reagent system and process design. It has advantages such as strong targeting, optimized reagent system, flexible process, good separation effect, high resource utilization rate, and environmental friendliness.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Understanding the Gold Mine Flotation Process

- Nickel ore priority flotation process(Sulfide ore)

- Lithium ore magnetic separation process

- Lithium Ore Processing: Gravity Separation and Flotation

- Chromite Gravity, Magnetic, and Electric Separation Process

- Complete Manganese Ore Gravity Separation Process

- Polymetallic Molybdenum Ore Processing: Magnetic Separation and Flotation

Leave a message with your needs or comments

Add comment: