The flotation process of sulfide fluorite type ore is a beneficiation method aimed at the characteristics of this type of ore, mainly achieving the separation of sulfide and fluorite through flotation.

Flotation process flow of sulfide fluorite type ore

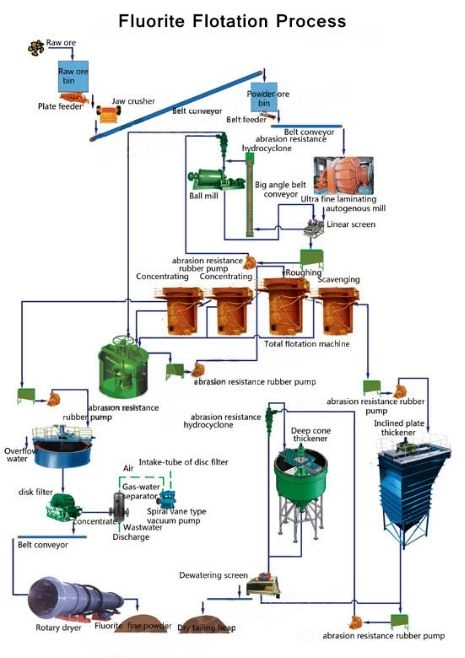

1.Sulfide priority flotation:In the flotation process, xanthate type collectors are first used to prioritize the flotation of sulfide ore. This is because the flotation performance of sulfides is usually better than that of fluorite, so sulfides can be separated from the ore through preferential flotation.

2.Fluorite flotation:After sulfides are preferentially flotation, their tailings are treated separately as fluorite ore. In fluorite flotation operations, fatty acid reagents are used for multiple selections to improve the recovery rate and concentrate quality of fluorite.

3.Residual sulfide inhibition:In the flotation process of fluorite, sometimes a small amount of sulfide ore inhibitors (such as cyanide) are added to suppress residual sulfides to ensure the quality of fluorite concentrate.

4.Concentrate Treatment:The fluorite concentrate obtained from flotation needs further treatment, such as washing and drying, to improve the quality of the concentrate.

Technological advantages

1.Efficient Separation:The flotation process of sulfide fluorite type ores achieves effective separation of sulfides and fluorite through priority flotation and multiple selections, improving the quality of the concentrate.

2.Flexible process design:Based on the specific characteristics of the ore, the type and dosage of reagents can be adjusted to adapt to different types of sulfide fluorite type ores.

3.Improve resource utilization:Through the flotation process, valuable metals and fluorite in ores can be maximally recovered, improving resource utilization efficiency.

4.Environmentally friendly:Compared with traditional flotation processes, this process reduces the use of chemical agents and has a smaller impact on the environment.

The flotation process of sulfide fluorite type ore achieves effective separation of sulfides and fluorite through precise reagent system and process design, with advantages such as efficient separation, flexible process design, improved resource utilization, and environmental friendliness.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Stepwise priority flotation process for copper ore

- Iron ore positive flotation process

- Gold Ore Thiourea Beneficiation

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Lithium ore reverse flotation process

- Lithium Ore Processing: Gravity Separation and Flotation

- Zirconium Ore Processing: Gravity Separation and Flotation

Leave a message with your needs or comments

Add comment: