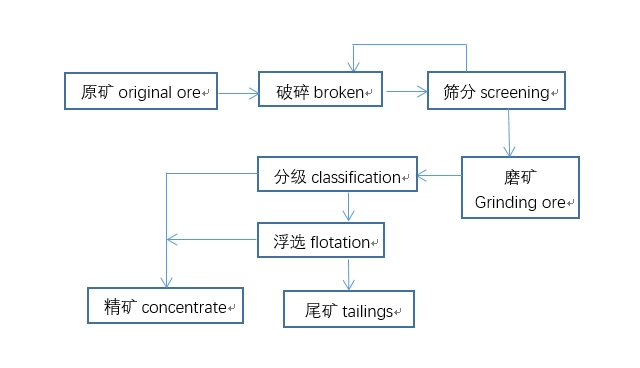

Bauxite is the main material for producing alumina, and its aluminum containing minerals are mainly boehmite, boehmite, or trihydrate; The aluminum silicon ratio (A/S) of bauxite is an important indicator for measuring the quality of bauxite.

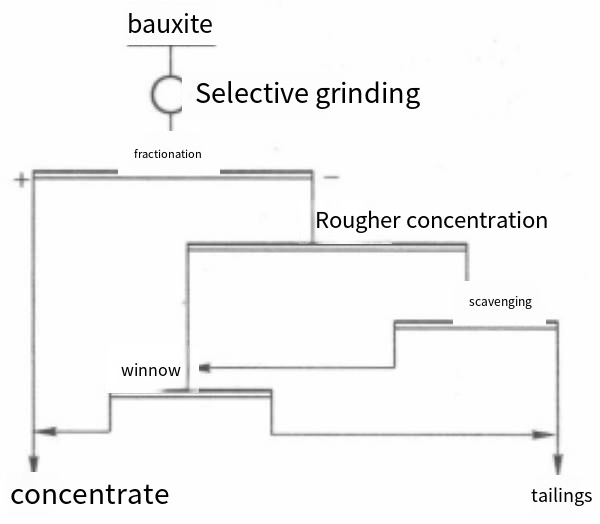

The selective grinding and agglomeration flotation process for bauxite is a special beneficiation method that fully utilizes the selective dissociation characteristics of bauxite. Through the steps of selective grinding and agglomeration flotation, the processing efficiency and concentrate quality of bauxite are improved.

Selective grinding and agglomeration flotation process flow of bauxite

1.Selective grinding:、

Bauxite undergoes coarse and fine crushing to a certain particle size for subsequent flotation treatment.

Selective grinding is a key step in this process, which adjusts the grinding fineness to achieve different degrees of dissociation between aluminum and silicon minerals, thereby improving the coarse-grained aluminum silicon ratio.

n the products after grinding, the coarse-grained minerals mainly contain aluminum minerals, while the fine-grained minerals contain more silicon minerals and impurities.

2.Cluster flotation:

Coarse grained products are directly produced as concentrates, which contain high aluminum content and fewer impurities.

Fine grained products are subjected to agglomeration flotation treatment. By adding specific agglomerants, fine-grained silicon minerals and impurities form hydrophobic agglomerates that float up to the surface of the slurry.

Hydrophobic aggregates in the flotation foam layer are collected and further separated to obtain high grade silica concentrate.

Technological advantages

Reduce the dosage of reagents:By selective grinding, the aluminum silicon ratio of bauxite is increased, resulting in a reduction in the required dosage of reagents for subsequent flotation treatment.

Improving processing capacity:The combined process of selective grinding and agglomeration flotation has improved the processing efficiency and capacity of bauxite.

Improving flotation indicators:Agglomeration flotation can effectively separate fine-grained silicon minerals and impurities, thereby improving flotation indicators and enhancing concentrate quality.

The selective grinding and agglomeration flotation process of bauxite fully utilizes the selective dissociation characteristics of bauxite, reduces the use of reagents, improves processing capacity, and improves flotation indicators through the steps of selective grinding and agglomeration flotation. It is an efficient bauxite beneficiation process.

Typical beneficiation plant

China Aluminum Zhongzhou Branch: The raw ore aluminum silicon ratio is 5.0-5.7. the concentrate aluminum silicon ratio is 10.3-11.7. and the concentrate recovery rate is 84.5% -89.0%.

- Random article

- Popular articles

- Popular comments

- Reverse flotation beneficiation process for bauxite

- Iron Ore Combined Beneficiation Process

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Gravity combined beneficiation process for wolframite ore

- Floatability flotation process for lead-zinc ore

- Lithium ore heavy medium beneficiation process

- Radioactive beneficiation and flotation process for uranium ore

Leave a message with your needs or comments

Add comment: