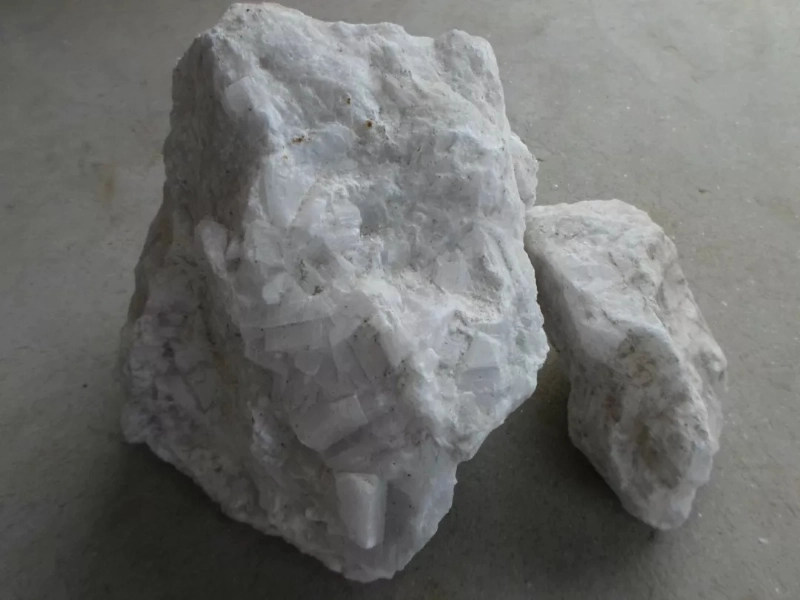

The barite magnetic separation method is mainly based on the difference in surface magnetism between barite and iron oxide minerals for sorting, and is commonly used to select some iron containing minerals such as siderite in barite ore. Magnetic separation method is usually used in combination with gravity separation method to produce barite raw materials as barium based drugs with low iron requirements.

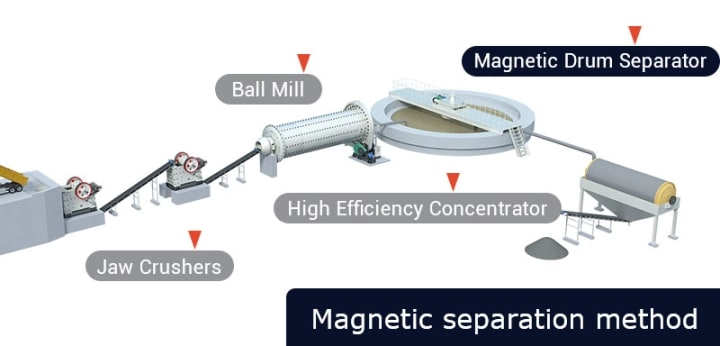

Process flow of barite magnetic separation

1.Crushing and grinding

The raw ore is first subjected to coarse crushing by a jaw crusher, and then to intermediate crushing by a cone crusher, grinding the ore into fine powder to facilitate better contact between the magnetic separator and the mineral surface.

2.Magnetic Separation

The slurry after crushing and grinding flows into a magnetic separator, which uses the magnetic difference between barite and iron oxide minerals for sorting.

During the magnetic separation process, barite is not adsorbed by the magnetic separator due to its low magnetism, while iron oxide minerals are adsorbed and separated by the magnetic separator due to their high magnetism.

3.Reverse flotation

The slurry after magnetic separation flows into the reverse flotation machine, and specific flotation agents are used to further separate iron oxide minerals that were not completely separated during the magnetic separation process.

By adjusting the type and dosage of flotation agents, as well as the pH value of the slurry, effective separation of iron oxide minerals can be achieved.

4.Concentration and drying

The slurry after reverse flotation is concentrated to remove excess water and obtain a relatively dry barite concentrate.

Finally, the concentrated barite concentrate is dried to obtain the final product.

Technological advantages

1.Efficient sorting:Magnetic separation can effectively separate barite and iron oxide minerals, improving the purity and grade of the product

2. Good selectivity:By combining magnetic separation and reverse flotation, effective separation of barite and iron oxide minerals can be achieved, reducing the inclusion of associated minerals.

3.Strong adaptability:Magnetic separation technology can adapt to different types and grades of barite ore, with good flexibility.

4.Flexible operation:The adjustment of magnetic separation and reverse flotation conditions, such as the strength of the magnetic separator, changes in the type and dosage of flotation agents, can enable the process to adapt to different ore characteristics.

5.Economically Reasonable:Compared with other mineral processing methods, magnetic separation usually has better economic efficiency in processing barite ore.

6.Environmentally friendly:The use of chemicals in the magnetic separation process is relatively small, and the impact on the environment is relatively small.

The barite magnetic separation process has the advantages of efficient sorting, good selectivity, strong adaptability, flexible operation, economic rationality, and environmental friendliness, and is an effective beneficiation method suitable for barite ore.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore flotation+gravity separation+magnetic separation process

- Branch serial flow flotation process for lead-zinc ore

- Chromite Processing: Gravity, Magnetic, and Flotation Separation

- Effective antimony ore gravity separation method

- Efficient purification of manganese ore by magnetic separation process

- Understanding the Manganese Ore Flotation Process

- Effective Flotation Processes for Copper-Molybdenum Ores

Leave a message with your needs or comments

Add comment: