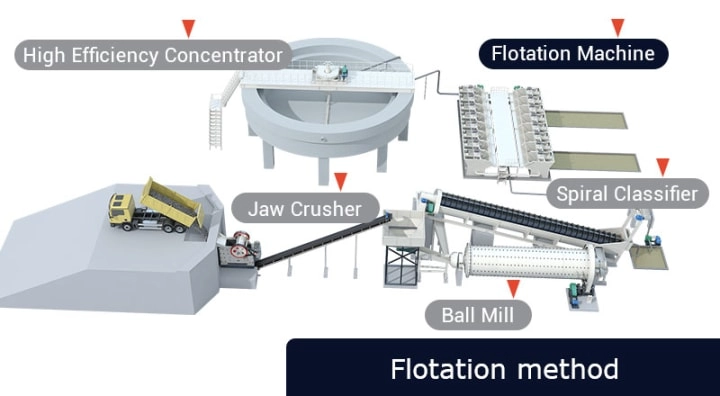

The specific gravity of barite is relatively high, ranging from 4 to 4.6. indicating good floatability. The flotation method of barite is mainly based on the differences in surface physical and chemical properties between barite and associated minerals for sorting. It is commonly used for sedimentary barite ores and hydrothermal barite ores associated with sulfide ores, fluorite, and other minerals.

Process flow of barite flotation

1.Crushing and grinding

The raw ore is first roughly crushed by a jaw crusher, and then finely crushed by a ball mill to grind the ore into fine powder, in order to facilitate better contact between the flotation agent and the mineral surface.

2.Mixing

In the ball mill, adding NaOH to adjust the pH value of the slurry to 8-10 helps improve the flotation efficiency of barite.

At the same time, adding water glass as a modifier can help improve the viscosity and stability of the slurry.

3.Flotation

In a flotation machine, oleic acid anionic collectors are used to flotation barite. The solid concentration of the slurry is usually controlled between 40% -50%.

Cationic amine collectors are usually not given priority due to their low collection efficiency and sensitivity to slime.

4.Selection and Concentration

The flotation slurry is carefully selected to further improve the purity and grade of barite.

-Concentrate the selected barite concentrate to obtain the final product.

Technological advantages

1.Efficient sorting:The flotation method can effectively separate barite from other associated minerals, improving the purity and grade of the product.

2.Good selectivity:By adjusting the pH value and using flotation agents, high selectivity flotation of barite can be achieved, reducing the inclusion of associated minerals.

3.Strong adaptability :The flotation process can adapt to different types and grades of barite ore, with good flexibility.

4.Flexible operation: Adjusting flotation conditions, such as changes in pH value, type and dosage of flotation agents, can enable the process to adapt to different ore characteristics.

5.Environmentally friendly:The reagents used in the flotation process are relatively few, and their impact on the environment is relatively small.

6.Economically Reasonable:Compared with other mineral processing methods, flotation method usually has better economic efficiency in processing barite ore.

The barite flotation process has the advantages of efficient sorting, good selectivity, strong adaptability, flexible operation, environmental friendliness, and economic rationality, and is an effective beneficiation method suitable for barite ore.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Gold selection process using resin slurry method

- Gold Ore Carbon Slurry Beneficiation Process

- Carbon leaching beneficiation process for gold mines

- Sand gold beneficiation process

- Arsenic Gold Ore Wet Chemical Pretreatment Process

- Branch serial flow flotation process for lead-zinc ore

- Laterite Nickel Ore: Pyrometallurgical Treatment

Leave a message with your needs or comments

Add comment: