The barite re selection method is mainly based on the density difference between barite and associated minerals for sorting, including ore washing, screening, desliming, jigging, shaking and other process flows. It is often used to treat residual barite ore.

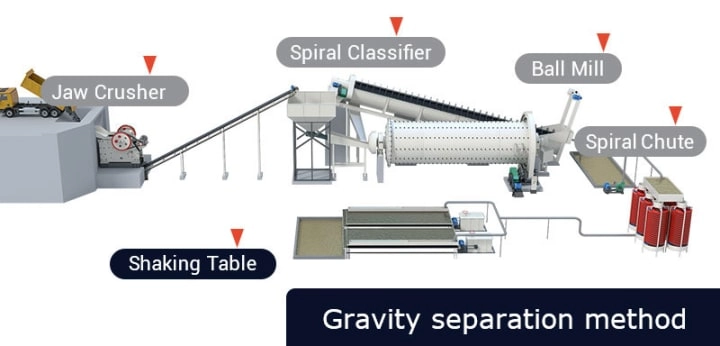

Gravity beneficiation process flow of barite

1.Ore washing:The purpose is to remove sediment and impurities from the surface of the ore and improve the purity of barite.

2.Screening:Screen the raw ore after washing to separate ores of different particle sizes, preparing for subsequent crushing and sorting operations.

3.Fragmentation:Use a jaw crusher or impact crusher to crush the screened ore into smaller particles.

4.Graded Desliming:Classify the crushed ore through classification equipment such as a cone classifier, while removing fine impurities such as sediment.

5.Jig sorting:Using a jigging sorting machine to sort ores based on their density differences, barite is selected due to its high density.

6.Shaker sorting:For smaller grain size barite, a shaking table is used for finer sorting to improve product grade.

7.Selected homework:Before the shaking table sorting, it may be necessary to use a hydrocyclone to remove mud and improve the sorting effect.

Technological advantages

1.Efficient Separation:The gravity separation method separates barite and other associated minerals based on the density difference of the ore.

2.Cost Benefit:Compared to chemical beneficiation, the gravity separation method usually has lower operating costs and relatively simple equipment requirements.

3.Environmentally friendly:The reselection method does not involve the use of chemical agents, so its impact on the environment is relatively small.

4.Strong particle size adaptability :For different particle sizes of barite, different sorting equipment can be used, such as jigs, shaking tables, etc., which have good adaptability.

5.High product quality :Through precise re selection process, high-grade barite concentrate can be obtained, with a grade of over 88%.

6. Easy to operate:Re selection equipment such as jigs, shakers, etc. are easy to operate and maintain.

The process flow of barite gravity separation has the advantages of efficient sorting, high cost-effectiveness, environmental friendliness, strong particle size adaptability, high product quality, and simple operation. It is an effective beneficiation method suitable for residual barite ore.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Lithium ore magnetic separation process

- Effective Gravity Beneficiation for Chromium Ore

- Manganese ore washing to achieve the best results

- Understanding the Manganese Ore Flotation Process

- Molybdenite Grinding and Separation Process

- Titanium Ore Processing: Magnetic Separation and Flotation

Leave a message with your needs or comments

Add comment: