Centrifuge basket is one of the key parts of centrifugal dehydration machine. It is is widely used in mining, petroleum, chemical, construction, machinery accessories.

Model:HWZ-1300k, HZI-1000. H-9. H-1200. H-800. H2-800

Half conical Angle : 13°, 20°

Maximum height : 90-700mm

Sieve basket gap: 0.3mm, 0.5mm

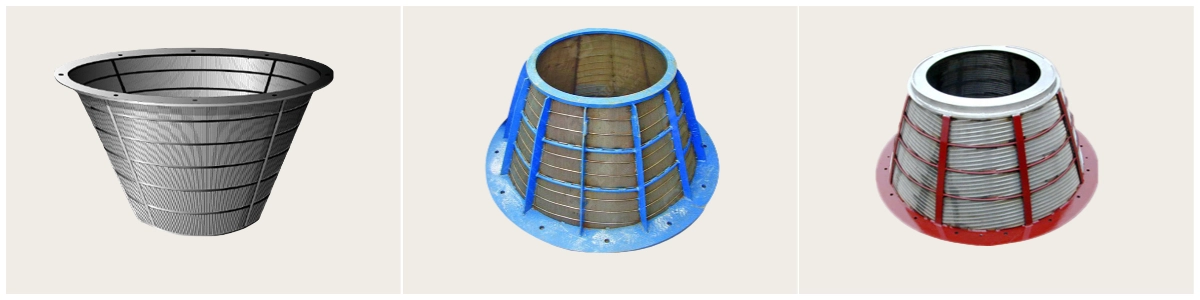

Centrifuge Basket

1.Brief Introduction of Centrifuge Basket

Centrifuge basket is one of the key parts of centrifugal dehydration machine. It is a high speed rotating component. When the screen basket is not only subjected to vibration load, but also bear the serious impact of coal and water, the intensity and accuracy requirements are relatively high. Varieties, specifications are more complete, can meet different coal types, different coal quality, the use of different screening requirements; the main process size is accurate, error is small, fixed bolt hole does not appear the wrong eyes, eye and other phenomena, so that the installation saves time and effort; good welding quality, structure is strong, no screen open welding, cracking and other phenomena; screen uniform, smooth, open hole, high permeability.

2.Materials of Centrifuge Basket

The main material of centrifuge basket includes low carbon steel, high manganese steel wire, stainless steel wire.

3.Advantages of Centrifuge Basket

3.1. Long service life, carrying capacity.

3.2. High screening efficiency.

3.3. Wide range of application, the application is stronger, and can be used for any type of vibrating screen machine.

3.4. High screening precision.

3.5. Low working noise, in line with national standards of environmental noise standards.

4.Application of Centrifuge Basket

Centrifuge basket is Widely used in mining, petroleum, chemical, construction, machinery accessories, door with a net, packaging, barbecue grill, barbecue net, sintering furnace net, with net hardware products, arts and crafts net, vibration screen, basket net, with net food machinery, cooking net, net wall, food, roads, railways, infrastructure with the net, for classification of solid material screening, liquid and slurry filtration, breed and civil.

5.Technical Parameters

| Model | Big end diameter (mm) | Inner diameter (mm) | Half conicalangle (°) | Maximum height (mm) | Sieve basket gap (mm) |

| HWZ-1300k | φ1312 | 13° | 700 | 0.5 | |

| HZI-1000 | φ1015 | 13° | 554 | 0.5 | |

| H-9 | φ919 | 20° | 475 | 0.5 | |

| H-1200 | φ1200 | 450 | 0.3 | ||

| H-800 | φ800 | 400 | 0.3 | ||

| H-800 | φ320 | 90 | 0.3 | ||

| H2-800 | φ801 | 290 | 0.3 |

6.Factory Display

We can provide customized design according to our clients’ demands and also refine our products by our clients’ feedback.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Iron Ore Roasting and Magnetic Separation Process

- Gold Mine Gravity Beneficiation Process

- Gold Ore Thiourea Beneficiation

- Gravity combined beneficiation process for black and white tungsten ore

- Lithium ore positive flotation process

- Effective Gravity Beneficiation for Chromium Ore

- Chromite Gravity and Magnetic Separation Process

Leave a message with your needs or comments

Add comment: