Our filter plate adopts imported TPE elastomer and high intensity PP, which make the filter plate not noly has the flexibility of the rubber plate.

Automatic Grade:Automatic

Material: Reinfoced PP and TPE

Certification:CE&ISO

Warranty: One Year

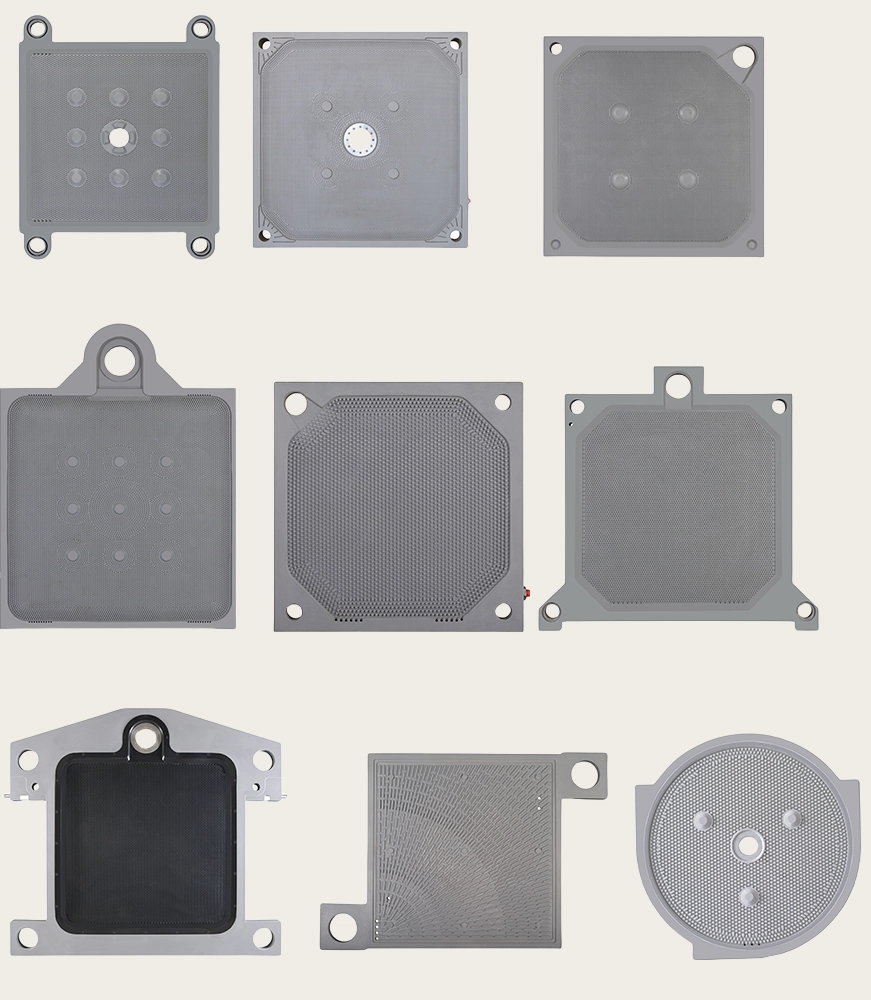

Membrane Filter Press Plate.

1. Brief Introduction

Our filter plate adopts imported TPE elastomer and high intensity PP, which make the filter plate not noly has the flexibility of the rubber plate, but also the tenacity and rigidity of the polypropylene plate that ensure the airtightness of the filter plate during pressing.All technical index of filter plate strictly complied with EU standard.The maximum membrane inflation pressure of high pressure PP membrane filter plates can be up to 4.0Mpa,which represents the most advanced level of the world.

2. Advantages

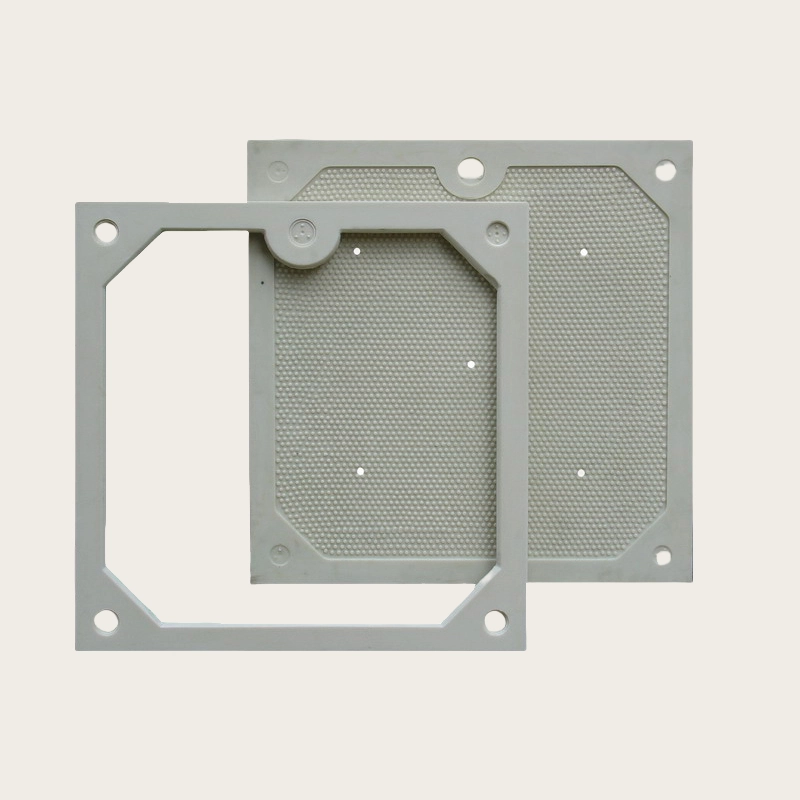

Filter plates adopt pp material to press mould, and the design of filtration surface adopts special channel, smooth and without any blockage.

Material of plate consists of TPE elastomer, fiber glass, and Polypropylene. So our plates have the advantage of flexibility, toughness, rigidity. After the process of the CNC machining center, the flatness of the filter plate is lower than 25µm which make sure excellent sealing when pressing, and without any leakage when feeding.

All specifications of our plates not only comply with China JB/T4333.3-2005 standard, but also comply with Germany DIN7129 standard , completely in common with the European&Amerian products.

Compared with the filtration plates manufactured according to national standards: filtration speed improved 20%, density and intensity, anti-fatigue ,anti-aging speed improved one times.

The maximum feeding pressure of the filter plate is 1.6Mpa. With the properties of high temperature and high pressure resistance, antisepsis and airtight, short filtering cycle, good processing effect and low humidity of the cake.

3. Features

Recessed chamber filter plate for filtration of water, food, mining, chemical, etc;

Resistance to high temperature and high pressure;

Not easy to be blocked in filtration. Lower water content of filter cake;

High efficiency for filtering and washing;

Long service life.

4.Common membrane filter press plate size

250. 450. 470. 500. 630. 720. 800. 900. 1000. 1200. 1250.1300. 1500. 1600. 1500*2000. 2000. 2500*2600. 3200. etc.

We also make special design for special industry.

5.Technical Parameter

| Filtering press | <0.6Mpa | Filtering temperature | <80°C |

| Main feeding diameter | DN100 | Washing inlet | DN50 |

| Filtering plate weight | About70KG | Out size (mm) | 2000*2000 |

| Filtering plate thickness | 60mm | Mud cake thickness | 30mm |

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Arsenic Gold Ore Wet Chemical Pretreatment Process

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Laterite Nickel Ore Hydrometallurgical Process for Oxide Ore

- Lithium ore magnetic separation process

- Effective Gravity Beneficiation for Chromium Ore

- Complete Manganese Ore Gravity Separation Process

- Combined Process for Manganese Ore Magnetic Separation and Flotation

Leave a message with your needs or comments

Add comment: