If you are confused about how to choose proper mineral processing solution for your mine and want to learn more about the selection parameters of mineral processing plant, you are exactly in the right place! Here I will show you the key selection parameters for mineral processing projects from the perspective of minerals, including metallic minerals, non-metallic minerals, and sand or placer deposit. Believe me, whoever you are, a mine owner or a dressing technician, this selection condition lists will be a helpful guide when you are going to build a plant or show expertise.

01Metallic minerals

Metallic minerals refer to minerals with obvious metallic properties, including gold ore, lead ore, iron ore, etc. The following selection conditions apply to all the metallic mineral processing plant election. Some non-metallic minerals like graphite, fluorite, barite also adopt these selection parameters.

Types of raw materials and solid treatment capacity. This is the most basic condition you need to considerate no matter what kind of mineral processing plant you want to build. The raw materials can be raw ore or tailings, and the capacity can the scale of the dressing plant. It should be noted that compare with daily and annual capacity, the and hourly capacity (t/h) is more suitable to choose a proper scheme.

Mineral grade or useful mineral content in the raw materials. This condition also belongs to basic conditions. When knowing the useful content, you will be possible to define the value of raw material and the concentrate yield.

Raw material element analysis and ore properties.The raw material element various based on the different key element. And the ore properties should conclude the data of phase analysis, density, hardness, mud content, etc. Knowing these information, you can determine the main impurity elements in the ore and design a more appropriate principle process.

Beneficiation test report.Beneficiation test is absolutely necessary in order to obtain the most suitable beneficiation technology and selection parameters.

Maximum particle size of the raw ore. The crushing stage process and machine selection will need this parameter to get modified.

Local voltage, frequency and altitude, and ore photos, etc. These supplementary conditions are usually used to confirm the previous conditions.

02Non-metallic minerals

Non-metallic minerals mainly consist of quartz, feldspar, graphite, fluorite, etc. Some non-metallic minerals like graphite, fluorite, barite will adopt the same selection parameters with metallic minerals to design a processing solution. while quartz and feldspar will apply to the following conditions.

Types of raw materials and solid treatment capacity. This is the most basic condition you need to considerate no matter what kind of mineral processing plant you want to build. The raw materials can be raw ore or tailings, and the capacity can the scale of the dressing plant. It should be noted that compare with daily and annual capacity, the and hourly capacity (t/h) is more suitable to choose a proper scheme.

Analysis of raw material elements. According to your mine, the primary element will be different. Having the analysis, you can determine the main impurity elements in the ore, and design better principle process.

Related data of ore properties (phase analysis, density, hardness, mud content, etc.) and beneficiation test reports. Here the most Appropriate beneficiation technology and selection parameters can be determined.

Maximum particle size of the raw ore. The crushing stage process and machine selection will need this parameter to get modified.

Local voltage, frequency and altitude, and ore photos, etc. These supplementary conditions are usually used to confirm the previous conditions.

03Sand or placer deposit

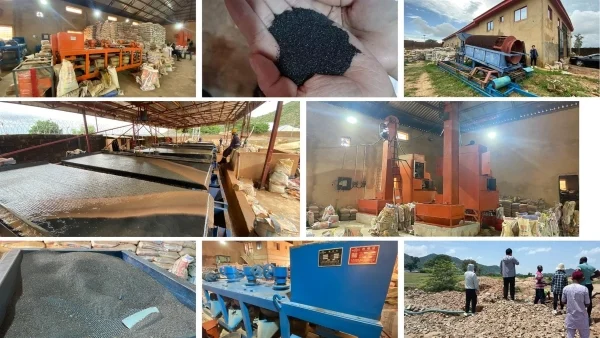

Sand deposit we often see is river sand, placer gold, silica sand, etc. here I will only include the selection parameters of placer gold sand, also known as alluvial gold. If you want to know more selection conditions, about other sand deposit, you will contact me by leaving a message or inquire our online service.

Solids’treatment capacity (or scale of processing plant)- the most basic condition, required for any project. Give the mining consulting company the hourly treatment capacity (t/h), they will help design a scheme.

The grade of Au in the raw material. The basic value of the raw material and the yield of concentrate can be judged.

Analysis of raw material elements and the distribution of gold in each ore size. You will need a sieve analysis of raw ore particle size to get the distribution. It can be determined whether the raw materials contain other heavy minerals, and content of gravel and mud, which is helpful for the optimization of process and type selection

Other ore properties(phase analysis, density, hardness, mud content, etc.) and beneficiation test reports. In this stage, you will get the most suitable beneficiation process and selection parameters.

Local voltage, frequency and altitude, as well as ore photos, etc.

04To wrap up

Above I have introduced the mineral processing project selection conditions and parameters. You may notice that the selection parameters of different kind of minerals look much alike. Yes, they are! The details behind the conditions are what are important. We will need more detailed data to give the final sheme.

- Random article

- Popular articles

- Popular comments

- Copper Ore Flotation and Magnetic Gravity Combined Process

- Gravity beneficiation process for iron ore

- Carbon leaching beneficiation process for gold mines

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Zirconium Ore Separation: Gravity and Magnetic Methods

Leave a message with your needs or comments

Add comment: