Graphite, a critical raw material for various industries, undergoes a complex beneficiation process in graphite processing plants to obtain high-quality graphite concentrates. One crucial step in this process is the screening and classification of graphite particles to achieve the desired particle size distribution. Effective screening and classification methods ensure optimal separation efficiency and improve the overall performance of graphite processing operations. This article explores the different screening and classification methods employed in graphite processing plants, their advantages and limitations, challenges faced during the process, and future trends and innovations in the field.

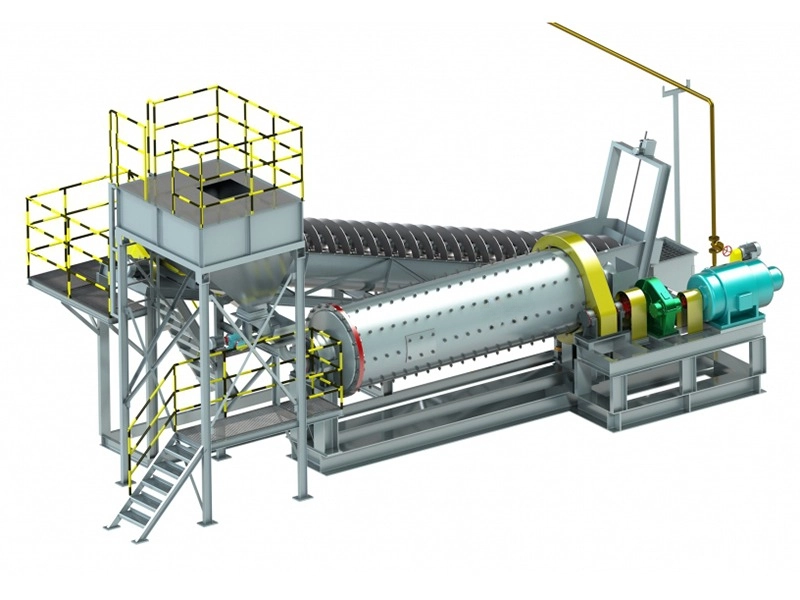

( A ball mill and a spiral classifier machine in a processing plant )

01Importance of Screening and Classification in Graphite Processing

In graphite processing plants, screening and classification methods play a crucial role in achieving the desired particle size distribution. The particle size of graphite directly affects its physical and chemical properties, as well as its suitability for specific applications. By effectively screening and classifying graphite particles, plant operators can control the particle size distribution, improve the efficiency of downstream processes, and produce graphite concentrates that meet the requirements of end-users.

02Traditional Screening Methods in Graphite Processing

Traditional screening methods commonly used in graphite processing plants include vibrating screens, trommel screens, and gyratory screens. Vibrating screens are versatile and widely used for primary screening, removing oversize particles and ensuring a uniform feed to subsequent stages. Trommel screens, consisting of a rotating cylindrical drum with perforated plates, are effective for coarse particle separation. Gyratory screens, with their unique gyratory motion, excel in precise particle size separation.

03Advanced Screening Technologies in Graphite Processing

To improve the efficiency and effectiveness of graphite screening, advanced technologies have been developed. High-frequency screens employ high vibration frequencies to enhance the separation of fine particles, resulting in improved screen efficiency and higher throughput. Flip-flow screens use elastic mesh panels that flex to prevent blinding and improve the capture of difficult-to-screen materials. Banana screens, characterized by their banana-like shape, offer increased screening surface area and improved particle retention.

04Particle Size Analysis Techniques

Accurate particle size analysis is essential for effective screening and classification in graphite processing plants. Various techniques, such as sieve analysis, laser diffraction, and image analysis, are employed to determine the particle size distribution of graphite samples. Sieve analysis involves passing the sample through a series of sieves with different mesh sizes to separate particles into size fractions. Laser diffraction measures the scattering of laser light to determine particle size distribution. Image analysis utilizes digital imaging techniques to measure particle dimensions and classify them based on size and shape.

05Particle Size Classification

Particle size classification is a crucial step in graphite processing that involves separating particles into different size ranges or fractions based on their dimensions. This classification process is important for achieving the desired particle size distribution and ensuring that the final graphite concentrate meets the specifications required by end-users. Several methods are commonly used for particle size classification in graphite processing plants, including hydraulic classifiers, spiral classifiers, and air classifiers. Hydraulic classifiers utilize centrifugal force, spiral classifiers rely on settling velocity in water, and air classifiers use airflow and mechanical forces for particle separation.

06Combination Approaches: Screening and Classification Integration

In some graphite processing plants, a combination of screening and classification methods is employed to achieve optimal particle size separation and classification. By integrating these two processes, plant operators can maximize the efficiency of particle separation and improve the overall performance of the beneficiation process. For instance, a common approach is to use a vibrating screen for primary screening to remove oversized material, followed by a classification method such as a hydraulic classifier or spiral classifier to separate the remaining particles based on their size and density.

07Challenges and Considerations in Graphite Screening and Classification

While screening and classification methods play a crucial role in graphite processing plants, they are not without challenges. Some common challenges include handling fine particles, screen and classifier maintenance, water management, and process optimization. Fine particles tend to agglomerate, leading to screen blinding or reduced classification efficiency. Regular maintenance is essential to ensure optimal performance of screening and classification equipment. Effective water management is crucial to minimize water consumption and prevent the loss of valuable graphite fines. Process optimization involves monitoring and adjusting factors such as feed characteristics, particle size distribution, and process parameters to maximize performance.

08Future Trends and Innovations

Future trends and innovations in graphite screening and classification include automation and artificial intelligence, novel screening materials, sustainable solutions, and advanced modeling and simulation. Automation and AI technologies enable real-time monitoring and optimization of screening and classification operations. Novel screen materials with improved wear resistance and self-cleaning properties enhance separation efficiency. Sustainable solutions focus on eco-friendly materials, water recycling systems, and energy-efficient equipment. Advanced modeling and simulation techniques facilitate process design, troubleshooting, and performance optimization.

09Conclusion

Efficient screening and classification methods are essential in graphite processing plants to ensure proper particle size separation and optimize the beneficiation process. Traditional and advanced screening technologies, along with particle size analysis techniques and classification methods, provide plant operators with a range of options for achieving the desired particle size distribution. Overcoming challenges such as handling fine particles, maintenance, and water management is crucial for smooth operations. Future trends and innovations, including automation, novel materials, sustainability, and advanced modeling, will continue to drive improvements in graphite screening and classification processes.

- Random article

- Popular articles

- Popular comments

- Scheelite Flotation Method

- Nickel ore priority flotation process(Sulfide ore)

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

- Effective Gravity Beneficiation for Chromium Ore

- Manganese ore washing to achieve the best results

- Complete Manganese Ore Gravity Separation Process

- Efficient purification of manganese ore by magnetic separation process

Leave a message with your needs or comments

Add comment: