gSpiral classifier is one of the important beneficiation equipments, which is widely used in the beneficiation plants of gold, iron and copper ores. In this article, we will mainly introduce how to choose a spiral classifier from the aspects of the introduction, type and price of the spiral classifier.

01 Spiral Classifier Introduction

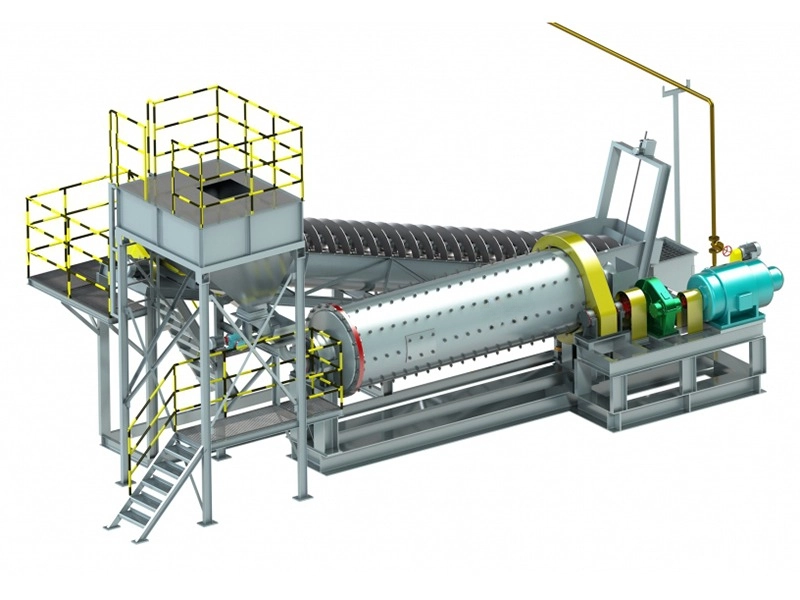

The spiral classifier relies on the principle that the specific gravity of the solid particles is different, so the sedimentation speed in the liquid is different, the fine ore particles float in the water to overflow, and the coarse ore particles sink to the bottom of the tank. It is a kind of classification equipment that discharges ore particles from the upper part of the screw to carry out mechanical classification. It can filter the material powder ground in the mill, and then use the spiral blade to rotate the coarse material into the feed port of the mill. Drain the filtered fines from the overflow pipe.

02 Spiral Classifier Types

(1). According to overflow dam height

According to the height of the overflow dam, that is, the position of the spiral in the water tank and the height of the pulp surface are different, the spiral classifier can be divided into three types: high dam type, low dam type and submerged type.

a. High Dam Spiral Classifier

The overflow dam position of the high dam type spiral classifier is usually higher than the bearing center of the lower end of the screw shaft and lower than the upper edge of the overflow end spiral, so the area of the settlement area is larger than that of the low dam type spiral classifier, and the height of the dam is also higher. It can be adjusted within a certain range, that is, the area of the sedimentation area can be slightly changed according to the classification requirements, so as to adjust the classification particle size.

b. Low Dam Spiral Classifier

The overflow dam of the low dam type spiral classifier is often lower than the center of the overflow end bearing, so the area of the settlement area is too small, the overflow production capacity is too low, and the agitation of the spiral on the slurry surface is large, so in actual production only It is used for washing sand ores with little mud and dewatering of coarse particles, and is rarely used in grinding and grading operations.

c. Submerged Spiral Classifier

The overflow end of the submerged spiral classifier generally has 4-5 spiral blades, and all the spiral blades are immersed under the liquid surface of the settlement area, so the area of the settlement area is large and the classification pool is deep.

Due to the difference in structure between the high dam type and the submerged type spiral classifier, the roles of the two in the classification operation are also different. The high dam type spiral classifier is more suitable for the classification of coarse particles larger than 0.15mm, and is often used in the first stage grinding; while the submerged spiral classifier has a stable classification surface, high overflow output and fine particle size. Therefore, it is more suitable for the separation of overflow products with a particle size of less than 0.15mm, and is often combined with the mill in the second stage of grinding.

(2). According to screw shaft number

According to the number of screw shafts, screw classifiers can be divided into single screw and double screw. The classification performance of the two is basically the same, but the double-screw classifier is significantly larger than the single-screw classifier in terms of sand return treatment capacity, overflow treatment capacity, and the same size of the spiral diameter, and the price of the double-screw classifier is also much higher than that of the single-screw classifier. Therefore, it is more suitable for use with large-scale grinding machines. Mineral processing experts suggest that under the determined processing capacity, the single-screw classifier should be used as much as possible. According to statistics, the spiral working load of the double-screw classifier is 0.6-0.75 times that of the single-screw classifier, and the efficiency is relatively low. Therefore, when choosing a spiral classifier, the appropriate spiral speed and number must be determined according to the processing capacity.

The above-mentioned various types of spiral classifiers have their own advantages, and also have different degrees of influence on the classification efficiency of the equipment. According to the current different grading requirements, different types of grading equipment have been optimized and improved accordingly, in order to achieve good grading results. Therefore, when each dressing plant chooses grading equipment, it must clearly grasp its type characteristics and working principle, and consider the ideal process flow and equipment in combination with its own processing plant production needs.

03 Spiral Classifier Prices

The price of the spiral classifier is affected by factors such as manufacturing cost, equipment performance, market demand, and brand awareness. The manufacturing cost and the manufacturer's cost of producing the spiral classifier will directly affect the price setting of the equipment; the performance and quality of the spiral classifier will directly affect the price of the equipment, and the price of the spiral classifier with reliable performance and excellent quality is higher. This is undeniable. Therefore, when purchasing a spiral classifier, users must not only focus on the price of the equipment, but also on the performance and quality of the equipment. Otherwise, buying equipment with poor quality at a lower price will bring immeasurable losses. With the changes in the exploitation and production of resources in our country, the domestic market demand for spiral classifiers continues to rise, and the market demand is relatively large, which also leads to the continuous increase in the price of the equipment. Brand awareness will also have a certain impact on the price of spiral classifiers. Of course, the price of spiral classifiers produced by domestic big brands is relatively high, and the spiral classifiers produced by unknown small brands have less market share and less investment cost. , the equipment price is correspondingly lower.

04Summary

According to the properties of various ores with different characteristics and the actual situation of the processing plant, we should pay more attention to the performance of the classifier when selecting the classification equipment, and pursue higher quality prices under the condition of ensuring the performance. Click here for more details and pricing information on Spiral Classifiers.

- Random article

- Popular articles

- Popular comments

- Understanding the Gold Mine Flotation Process

- Lead-zinc Ore Asynchronous Flotation Process

- Laterite Nickel Ore: Pyrometallurgical Treatment

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

- Chromite Gravity and Magnetic Separation Process

- Effective Flotation Processes for Copper-Molybdenum Ores

- Titanium Ore Processing: Magnetic Separation, Gravity Separation, Flotation

Leave a message with your needs or comments

Add comment: