Using external vacuum power, your liquid is pumped away for filtration using a plate and frame filter.

As part of the zinc powder replacement process, it is widely used in the purification section of gold-leaching solutions.

Description

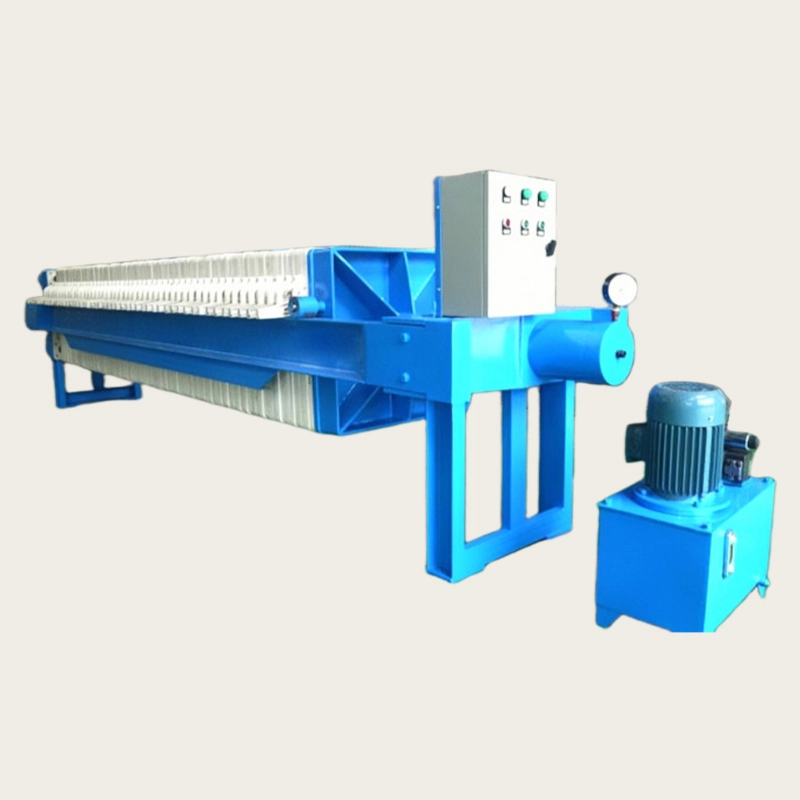

Name: Plate and frame purification tank, Frame filter tank, filter press, cyanide equipment

Filtering area: 45-90 ㎡

Product advantages: no moving parts, convenient operation and maintenance.

Scope of application: it is widely used in the purification section of leaching precious liquid in the replacement process of gold and zinc powder.

Working principle

The filter press cloth is used as the filter medium to separate solids and liquids. Under the action of vacuum, the clear liquid penetrates the filter cloth, and the fine particles adhere to the filter cloth’s surface to achieve solid-liquid separation.

Plate and Frame Johkasou The plate and frame Johkasou produced by Jilin Prospecting is special equipment for the purification of precious liquid before the deoxidation of the precious liquid in the gold cyanide gold production process.

Frame purification tank function is to remove the suspended solid impurities such as mud in the precious liquid after solid-liquid separation, and obtain a pure liquid to improve the grade of the replaced gold mud, reduce the production cost of pyrometallurgical smelting, and create qualified high-grade gold. Favorable conditions.

This equipment is simple in structure, convenient to maintain, easy to operate, and can be alternately cleaned during operation, and has a long service life. The liquid collector of each filter piece of this equipment is directly connected with the deoxygenation tower, and the vacuum in the deoxygenation tower can be used to suck the purified precious liquid for deoxygenation.

| Model | Filtration area (m2) | Volume of cylinder(m³) | Max filtration pressure(Mpa) | weight (kg) |

| BKC-45 | 45 | 5.62 | 100 | 2021 |

| BKC-70 | 70 | 9.04 | 3064 | |

| BKC-90 | 90 | 11.78 | 3900 | |

| BKC-100 | 100 | 13.15 | 4317 | |

| BKC-140 | 140 | 18.62 | 5152 |

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore flotation+gravity separation+magnetic separation process

- Gold Mine Gravity Beneficiation Process

- How to Extract Gold Using Mercury

- Gold Mine Combined Beneficiation Process

- Gold Ore Thiourea Beneficiation

- Gold Ore Carbon Slurry Beneficiation Process

- Arsenic Gold Ore Oxidation Roasting Pretreatment Process

Leave a message with your needs or comments

Add comment: