High efficient mineral thickener is used for concentrate concentration and tailings dewatering before filtration. The purpose of tailings dewatering with thickener is to use circulating water and facilitate tailings storage in a tailings dam.

Gravity sludge thickener is one of the necessary dewatering equipment in the production process of mineral processing technology.

Description

Product name:GX High eiffciency thickener,thickening equipment,gravity sludge thickener,thickener tank

Precipitation area:2.54-7846m²

Processing capacity: 5.6-30t/d

Product features: corrosion resistance, acid and alkali resistance, simple operation

Product improvement: inner diameter up to 100m

Scope of application: This thickener is widely used in metallurgy, chemical industry, coal, non-metallic mineral processing, environmental protection and other industries.

Uses: This thickening equipment is suitable for the dewatering of concentrates and tailings in concentrators, increasing the 20-30% pulp to 40-70%.

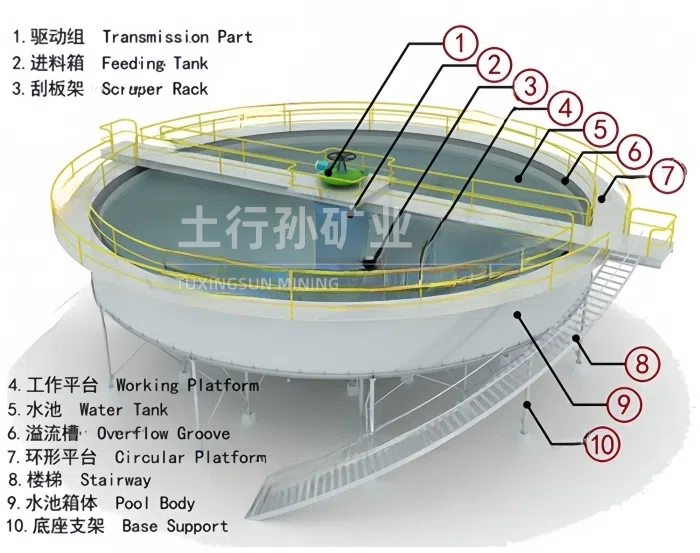

Structure: Tank body, degassing tank, feeding mixing drum, motor transmission device, rake frame lifting device, slow flow device, overflow weir, rake frame, feeding device, vertical shaft.

Features

1. In order to speed up the settling process, add flocculant to increase the particle size of settled solid particles.

2. Shorten the settlement distance of ore particles by installing inclined plates.

3. Flocculation, filtration, compression, and an increase in the processing capacity of the thick phase layer of mud deposition.

4. Equipped with automatic controls.

Adding a certain amount of flocculant to an ore pulp in order to concentrate it makes the ore particles form flocs, which settle quickly, thus increasing the concentration efficiency.

Working Principle

Thickeners equipment generally consist of circular thickening tanks and rake scrapers. Raw water emerges from the bottom of the pond through the upper part of the central buttress, and after being channeled by the diversion cylinder, it flows radially to the effluent from the sump around the pond. Under the action of the driving device, the end running wheels of the rotating truss rotate along the track around the pool, taking the center support as the center of the circle. Drive the lower scraper slowly, scrape and collect the sediment into the sludge collecting tank in the center of the sedimentation tank, and pump it out, while simultaneously scraping the upper scum into the slag discharge hopper for discharge.

Concentrating flotation concentrates: how to prevent metal loss?

When concentrating the flotation concentrate, because the pulp has a lot of foam, it often brings difficulties to the operation of the gravity thickener equipment, making the overflow turbid, and resulting in a large amount of metal loss in the overflow. Therefore, these foams should be removed before concentration.

There are several ways to eliminate foam:

1) When the pulp enters the mineral thickener machine, spray the wine with high-pressure water to eliminate the foam;

2) Disperse the air bubbles by the rotation of the impeller of the centrifugal pump;

3) Install a retaining ring parallel to the overflow tank in the sludge thickening equipment(the upper weir of the retaining ring is slightly higher than the overflow tank, and the lower edge is immersed in the liquid surface) to block the foam, and add chemicals to promote the rapid rupture of the foam.

| Model | Inner Diameter of Tank (mm) | Tank Height (mm) | Subsidence Area (m2) | Rabble Rotating Speed (r/min) | Lifting Height of the Rabble (mm) | Driving Motor Model | Driving Motor Power (kW) | Lifting Motor Model | Lifting Motor Power (kW) | Steel Tank Weight (kg) | Weight (kg) |

| GX-3.6 | 3600 | 1700 | 10.2 | 1.1 | 200 | Y100L-6 | 1.5 | Y100L-6 | 1.5 | 2829 | 6650 |

| GX-5.18 | 5182 | 2134 | 21 | 0.4 | 300 | Y132S-6 | 3 | PZ0.8AB | 0.8 | 5342 | 10460 |

| GX-6 | 6000 | 2500 | 28.3 | 0.8 | 300 | Y132M1-6 | 4 | Y132S-8 | 2.2 | 6506 | 10573 |

| GX-7.5 | 7500 | 2800 | 44.1 | 0.427 | 300 | Y132M2-6 | 5.5 | Y132S-8 | 2.2 | 10258 | 17320 |

| GX-9 | 9000 | 2800 | 63.6 | 0.427 | 300 | Y132M2-6 | 5.5 | Y132S-8 | 2.2 | 15980 | 23680 |

| GX-12 | 12000 | 3600 | 110 | 0.35 | 300 | Y132M-4 | 7.5 | Y100L1-4 | 2.2 | 25589 | 42756 |

| GX-15 | 15000 | 4000 | 177 | 0.15 | 300 | YCT200-4B | 7.5 | Y112M-6 | 2.2 | 36050 | 59000 |

| GX-18 | 18000 | 4400 | 254 | 0.13 | 400 | YCT200-4B | 7.5 | YTC752A-44 | 5.5 | 52485 | 73296 |

| GX-20 | 20000 | 4400 | 314 | 0.13 | 400 | YCT200-4B | 7.5 | YTC752A-44 | 5.5 | 59365 | 76020 |

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Iron ore positive flotation process

- Prioritized Flotation Process for Lead-zinc Ore

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Effective antimony ore gravity separation method

- Manganese Ore Reduction Roasting and Magnetic Separation Process

- Titanium Ore Processing: Gravity, Magnetic, Flotation, Electric Separation

- Rutile Electric Separation, Magnetic Separation, and Gravity Selection Process

Leave a message with your needs or comments

Add comment: