Description

Name: electromagnetic vibration feeder,Electromagnetic Vibrating Feeder

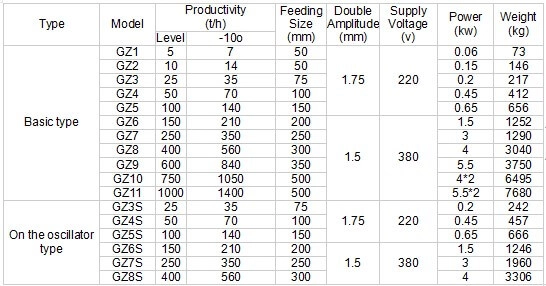

Productivity: 5-1400t / h

Power: 0.1-13kw

Particle size: 50mm-500mm

Basic models: (gz1–gz11), up vibration type, closed type, light groove type, flat groove type, wide groove type, round tube type, and extra large type.

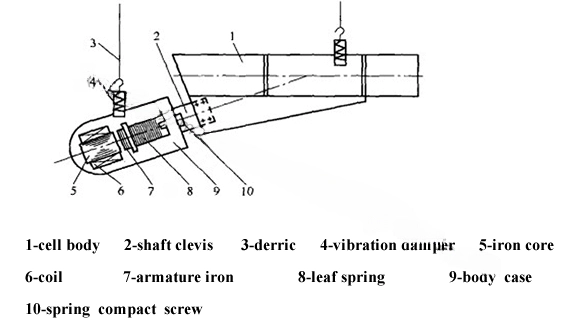

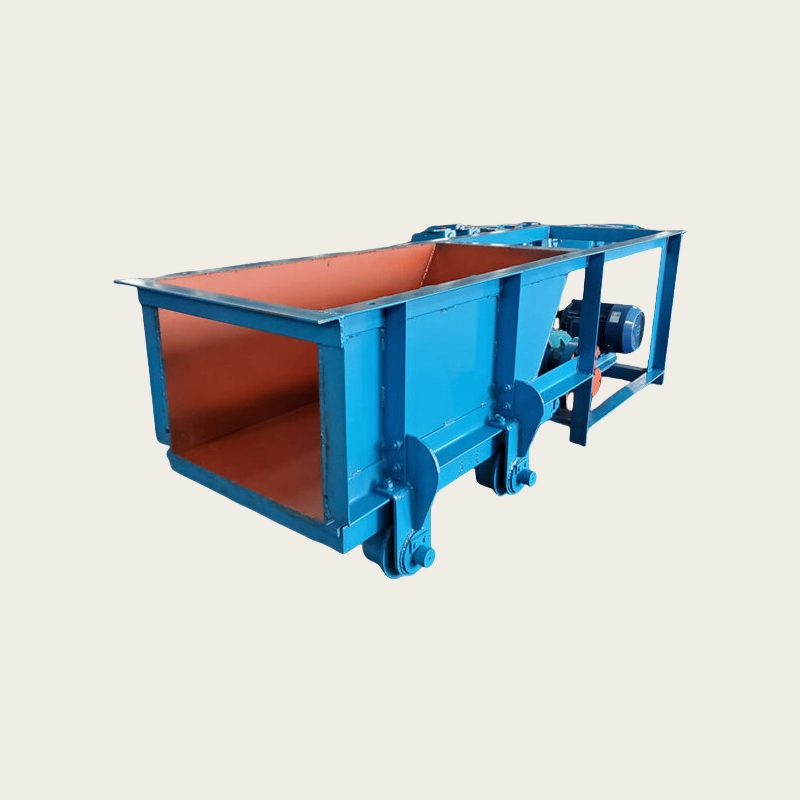

Structure: electromagnetic vibration feeder is composed of material trough, electromagnetic vibrator, shock absorber and control box.

Feeding mode: Automatically control the production process and feed to the receiving device (equipment) evenly, continuously, or quantitatively.

The GZ series electromagnetic vibration feeders are used in mining, metallurgy, coal, building materials, light industry, chemical industry, electric power, machinery, grain, and other industries to feed block, granular, and powdery materials evenly, continuously or quantitatively. It also allows for stepless adjustment of feeding quantity, centralized control, and automatic production process control.

Working principle

A single-phase half wave rectifies the current of the electromagnetic coil of the electromagnetic vibrating feeder. A pulse electromagnetic force is generated between the armature and iron core when the coil is connected, and a current flows through the positive half cycle. The slot moves backward and the main spring of the exciter deforms, storing a certain amount of potential energy. When there is no current flowing through the negative half cycle coil, the electromagnetic force disappears, and the main spring releases energy, causing the armature and iron core to move away from the slot.

Due to this, the electromagnetic vibration feeder vibrates back and forth at the frequency of the AC power supply. Material in the tank moves continuously along the trajectory of parabola because the bottom plane of the tank is at an angle to the action line of the exciting force. It is possible to control the feeding volume of the equipment by adjusting the rectifier voltage.

magnetic vibration feeder has the following characteristics

1. Its small size, light weight, simple structure, easy installation, no rotating parts, no lubrication, convenient maintenance, and low operation costs;

2. The bimorph operates in the low critical near resonance state because of the resonance principle of mechanical vibration;

3. The feeding quantity is highly accurate due to the ability to change the material flow and open and close it instantly;

4. Control of production processes can be centralized and automated;

5. There is little wear on the feeding trough;

6. Alloy steel plate material troughs are suitable for conveying high-temperature, severely worn, and corrosive materials;

7. Exposition-proof requirements cannot be met with this product.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Magnetic separation and beneficiation process for bauxite

- Gravity beneficiation process for iron ore

- Gold Ore Thiourea Beneficiation

- Cyanide Gold Preparation

- Lithium ore positive flotation process

- Lithium ore combined beneficiation process

- Uranium Ore Radioactive Treatment Process

Leave a message with your needs or comments

Add comment: