A gravity spiral chute is a kind of mining and mineral processing equipment, especially suitable for coastal, river, beach, and stream.

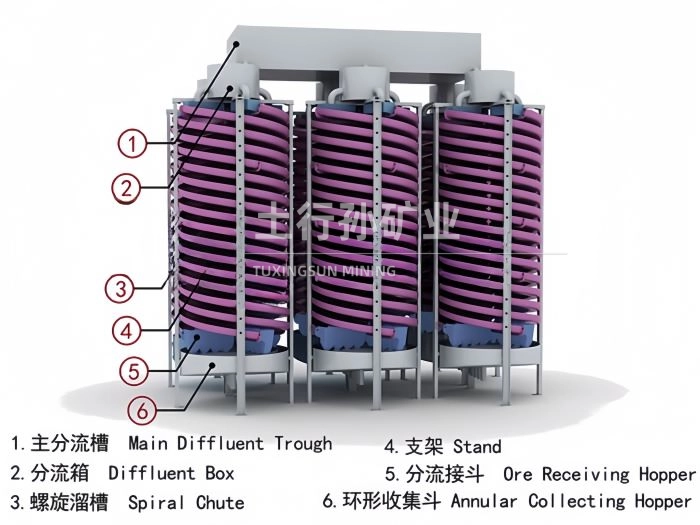

The main components of the spiral separator equipment are bolted together by spiral blades made of glass fiber reinforced plastic.

FRP spiral gravity chute conveyors are comprehensive spiral ore washing machines, materials handling equipment, shaking tables, and centrifugal separator characteristics.

Description

A new high-efficiency reselection equipment has been installed in the gravity spiral chute . The centrifugal concentrator is used for the separation of iron, tungsten, tantalum, niobium, gold mines, coal mines, monazite, rutile, zircon and other metal and non-metal minerals with sufficient specific gravity differences and particle sizes of 0.3-0.02 mm. In order to pass the appraisal, the Ministry organized relevant scientific research, design, universities, factories, and mines. According to them, the equipment had excellent performance, advanced sorting indicators, and had proven to be mass produced and popular.

Application

It is used to separate iron, tin, tungsten, tantalum, niobium, gold mines, coal mines, monazite, rutile, zircon and other metal and non-metal minerals with sufficient specific gravity difference with a particle size of 0.3-0.02 mm.

Method and Principle of gravity spiral chute

Install the spiral chute conveyor, align the vertical line, and fix it in a suitable position with an iron frame or wood. Sand will be pumped to the two inlets on top of the screw by the sand pump. Add supplemental water to adjust the ore concentration. Minerals are naturally occurring. An inertial centrifugal force is created in the flow velocity of the rotating slope by the swirling flow from high to low. The difference in the specific gravity, particle size and shape of the ore is used to separate the ore from the sand through the action of the gravity and centrifugal force of the swirling flow. The inflow concentrate bucket is connected with a pipeline, and the tailings flow into the tailing bucket with a pipeline connected to the sand tank, and then drained with a sand pump, completing the whole process of beneficiation.

According to the particle size of the processed mineral material, the gravity spiral chute can be divided into three categories

① In a Coarse-grained spiral chute, the maximum particle size of ore feeding is more than 2-3mm, up to 100-200mm.

② Placer chute to handle 2-3mm size ore.

③ Slime chute with feed particle size less than 0.074mm.

Features

1. Reasonable structure and small occupation area;

2. High recovery, high efficiency, and precise separation;

3. Light in weight, rush and corrosion resistant;

4. Simple installation and minimal maintenance requirements;

5. Low operating cost and long operating life;

6. Reliable running with minimal operator attention;

7. Strong adaptability to fluctuation of feeding amount, density, size and grade;

| Model | Spiral diameter (mm) | screw pitch (mm) | lateral dip angle (° ) | Spiral number | Feed particle (mm) | Feed density (%) | Production capacity (t/h) | boundary dimension (mm) | weight (t) |

| 5LL-400 | 400 | 240.180 | 9 | 2 | 0.2-0.02 | 25-55 | 0.15-0.2 | 460*460*1500 | 0.05 |

| 5LL-600 | 600 | 450.360.270 | 9 | 3 | 0.2-0.02 | 25-55 | 0.8-1.2 | 700*700*1600 | 0.15 |

| 5LL-900 | 900 | 675.540.405 | 9 | 4-2 | 0.3-0.03 | 25-55 | 2-3 | 1060*1060*4000 | 0.40 |

| 5LL-1200 | 1200 | 900.720.540 | 9 | 4-2 | 0.3-0.03 | 25-55 | 4-6 | 1360*1360*5230 | 0.60 |

| 5LL-1500 | 1500 | 540.720 | 9 | 4-2 | 0.3-0.02 | 25-55 | 8-6 | 1560*1560*5230 | 0.80 |

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Arsenic Gold Ore Wet Chemical Pretreatment Process

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Lithium ore positive flotation process

- Chromium Ore Gravity Separation and Flotation Process

- Efficient purification of manganese ore by magnetic separation process

- Effective Flotation Processes for Copper-Molybdenum Ores

Leave a message with your needs or comments

Add comment: