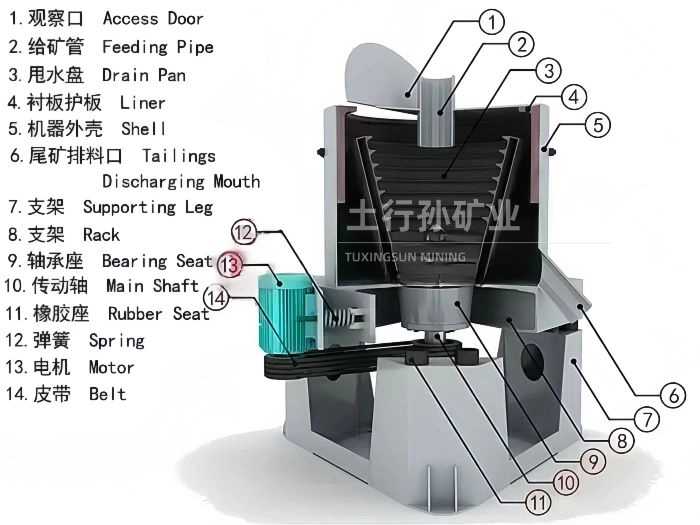

STL jacket centrifugal concentrators, also known as Nelson centrifuge, an important gravity separation equipment, which is a kind of centrifugal mineral processing equipment developed and produced by using the principle of gravity acceleration. It is suitable for monomer gold recovery of alluvial gold, vein gold ores, and polymetallic ores, replacing mercury plate operations. It can also be used for the selection of gold-bearing heavy sand washed by gold chutes and gold dredgers.

Description

Beneficiation centrifuge is a new type of gravity beneficiation equipment based on the centrifugal principle. It is specially used to recover the useful minerals in the fine mud. The emergence of the beneficiation centrifuge effectively solves the problem of the traditional gravity equipment, which has poor separation effect on the mud and is even difficult to separate. disadvantages. Since the beneficiation centrifuge is a new equipment that has just been developed, many friends do not know it very well, so this article will explain the beneficiation centrifuge in detail for you.

Application

STLB type centrifugal sand separator is a kind of new sorting fine-grained ore gravity equipment, mainly used for gold, silver, tin, manganese, tungsten, iron, uranium, rare earth and other minerals beneficiation. In particular for placer gold and rock gold recovery, replace of the mercury plate operation. It becomes to the best choice for dry land gold, river gold, rock gold processing etc. After various of the gold processing experiment, the monomer separation gold recovery rate is above 99% Rock gold discharge cycle is 1-4 hours, placer gold is 4-8 hours, enrichment ratio is up to 500-1000 times.

Features

1. High concentrating ratio and high recovery

2. Stable and reliable operation

3. Environmentally friendly(No chemical, No mercury)

4. Low water and Low electricity requirement

5. Low production cost, easy operation and maintenance

6. Fewer space requirements

When the beneficiation centrifuge is in operation, the high-speed rotation of the rotor can generate a large centrifugal force, and the use of centrifugal force to conduct the beneficiation of the slip film can effectively strengthen the gravity separation process and solve the problem of recovering fine-grained minerals. The beneficiation efficiency is low, and it is very suitable for processing 0.075-grain sludge.

What is the process of the beneficiation centrifuge?

Centrifugal concentrators operate by driving the drum at a high speed and sending the ore slurry to be treated to the inner wall of the drum at two points at the ore feeding port. With the drum, the pulp also runs at high speed. The heavy minerals deposit on the inner wall of the drum and rotate at high speed with the drum; The light minerals rotate with a certain speed difference, then in the process of rotation, they flow along the slope direction of the drum to the ore discharging end at a certain spiral angle, and finally discharge the tailings via the ore discharging separator at the end. As soon as the ore feeding separator has sorted for three minutes, it will reach the position of discharging the concentrate and stop feeding it to the inner wall of the drum. Upon discharge of the tailings, the ore discharging separator can automatically return to its original position to intercept the concentrate, and then the automatically opened high-pressure flushing water valve will first flush the concentrate deposited on the inner wall of the drum. The high-pressure water valve will automatically close after the concentrate is flushed. Upon discharge of the concentrate, the ore feeder and separator start the next separation cycle automatically.

| Model | Capacity (t/h) | Fluidization Water (m³/h) | Slurry Water (m³/h) | Feeding Density (%) | Feeding Size (mm) | Concentrate Weight (kg) | Power (kw) | Weight (t) | Dimension (mm) |

| STLB20 | 0-0.6 | 2-3 | 1.5-4 | 0-50 | 0-3 | 2 | 0.75 | 0.145 | 790*185*790 |

| STLB30 | 2-3 | 3-5 | 5-7 | 0-50 | 0-3 | 10-20 | 2.2 | 0.40 | 1180*1140*1250 |

| STLB60 | 8-12 | 7-10 | 8-12 | 0-50 | 0-3 | 30-40 | 4 | 1.00 | 1970*1670*1750 |

| STLB80 | 35-45 | 30-36 | 35-50 | 0-50 | 0-3 | 60-70 | 11 | 1.50 | 2300*1800*2200 |

| STLB100 | 70-80 | 55-80 | 70-120 | 0-50 | 0-3 | 80-90 | 22 | 2.00 | 2400*2000*2300 |

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore gravity separation+flotation+gravity separation process

- Iron ore positive flotation process

- Iron Ore Roasting and Magnetic Separation Process

- Gold Mine Combined Beneficiation Process

- Carbon leaching beneficiation process for gold mines

- Gravity combined beneficiation process for wolframite ore

- Branch serial flow flotation process for lead-zinc ore

Leave a message with your needs or comments

Add comment: