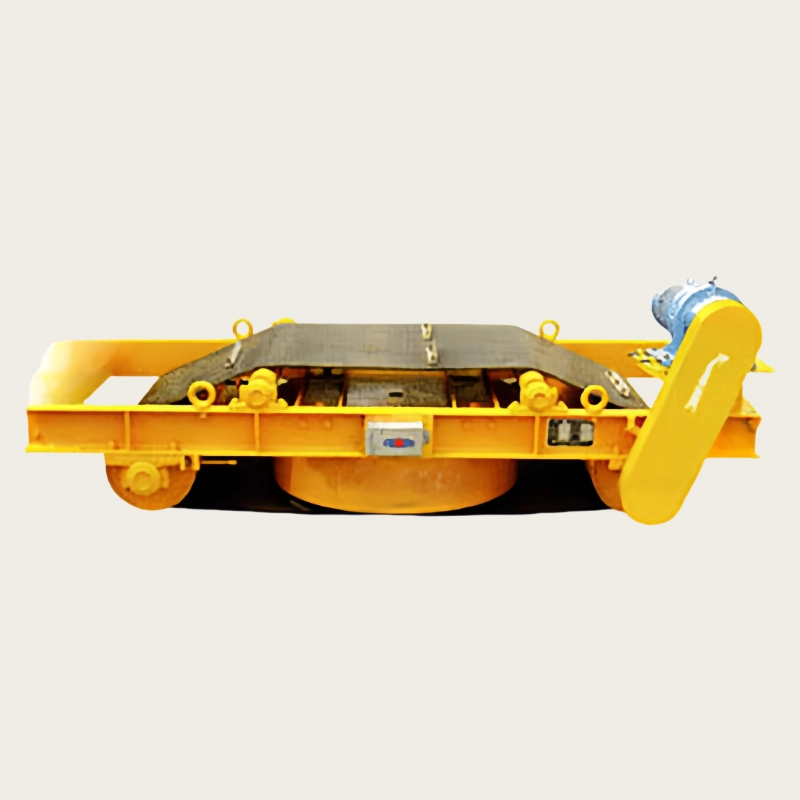

An electromagnetically magnetic separator (GPQ-885) can separate manganese ore, tungsten ore, tin ore, iron ore, titanium ore, chrome ore, garnet and other minerals with a magnetic induction strength of 18000 Ost.

Description

Single disc separator electromagnetic consists of two sections, i. e. Host unit (mechanical) and electrical unit (control cabinet). When the minerals to be separated are loaded into the bin, adjust the clearance between the magnetic disc tooth tip and conveying belt to a desirable range (generally about 1mm) and adjust the DC current of the control cabinet to the appropriate value (generally 4 6 A), depending on the mineral properties, particle size and separation requirements. Feed the materials into the permanent magnetic feeding drum, where the high-conductivity minerals will be removed. Through a feeding plate, the minerals will be uniformly sprayed onto the belt conveyor (The mineral thickness is generally between 0.2 and 0.8mm). When the machine is running, the belt conveyor will send the minerals down below the magnetic disc, where the paramagnetic minerals will be soon absorbed onto the tip of magnetic teeth. When the magnetic disc rotates to the low-intensity magnetic area, it will fall into the concentrate bin under the function of its gravity weight and centrifugal force. The diamagnetic minerals will be conveyed to the tailings bin via belt conveyor and discharged).

Features

Easy for operation and maintenance, One-time separate variety of ferromagnetic minerals, weakly magnetic, non-magnetic.

Operations can be adapted to water-lack mines.

Application

Single disc electromagnetic separator is mainly used for dry separation of weak magnetic minerals, such as tungsten, titanium, titanium, manganese and rare earth elements, which have a specific magnetization strip >40×10(-6).

| Specification | DME-855 | Field winding | 2 groups | Feed size | 〈4mm |

| Magnetic intensity | 15000Gs | Rated current | 3.5 A | Belt width | 520mm |

| Disk Diameter | 885mm | Power voltage | 380V/3phase | Capacity | 300-1600kgs/h |

| Disk quantity | 1 pcs | Motor power | 3kw | Dimension | 2500*1030*1600mm |

| Disk speed | 28-32r/min | Magnetizing power | 1.5kw | Weight | 3.2 tons |

- Random article

- Popular articles

- Popular comments

- Arsenic Gold Ore Oxidation Roasting Pretreatment Process

- Scheelite Flotation Method

- Zirconium Ore Separation: Gravity and Magnetic Methods

- Chromium Ore Gravity Separation and Flotation Process

- Titanium Ore Processing: Magnetic Separation and Flotation

- Titanium Ore Processing: Magnetic Separation, Gravity Separation, Flotation

- Rutile Gravity Separation, Magnetic Separation, and Flotation Process

Leave a message with your needs or comments

Add comment: