Description

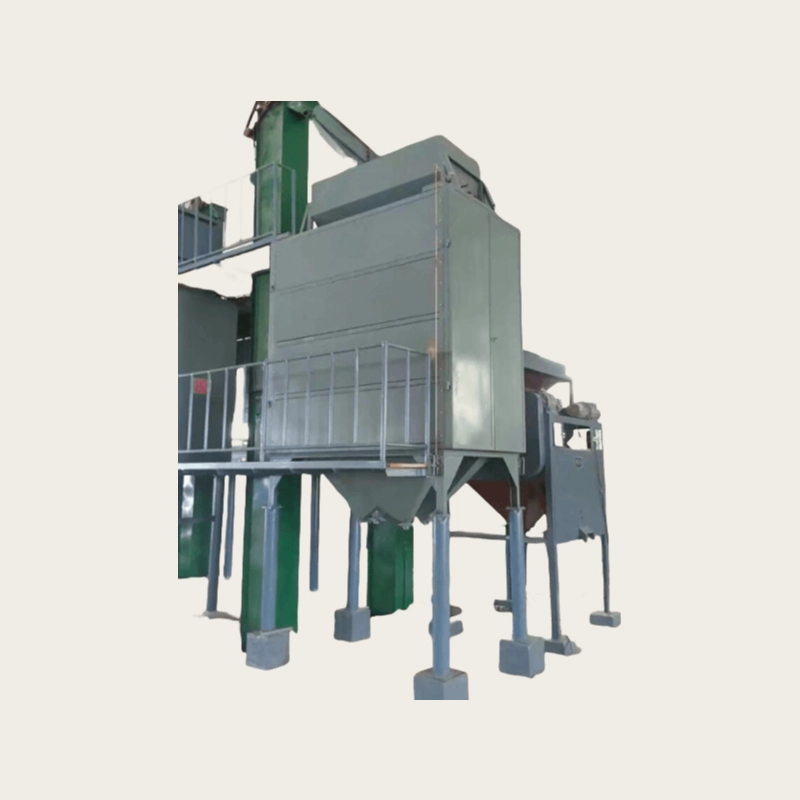

Double roller electrical sorter machine,The machine has small size,simple structure,convenient operation and maintenance,safe,effective separation and so on,It has big amount of users in China,and they are mainly exported to Vietnam, Korea ,Indonesia and other countries.

Application

φ120(φ220.φ165)×1500 double Roller Electrical Sorter is one of the major equipment in electricity mineral separation.It is widely used in sorting titanium,zirconium,rutile,monazite,iron,tungsten,tantalum,niobium,tin and other precious minerals, It can separate material which’s particle size is from 0.1 to 2 mm and surface temperature is less than 1% of itself, It often works well with the single-disc magnetic separator and permanent magnetic sorting machine in the process of sorting ilmenite, zircon ore and other minerals.

Working Principle

The Electrical sorting method used the differences of conductive of different mineral,Under the influence of electric field,mineral particles are subject to electrical and mechanical forces(centrifugal force,gravity,drag) role,then they produce different tracks that make them to be separated,so we can achieve the purpose of sorting.

When the temperature heated to 40˚C-60̊˚C after entered into the bin.the mineral particles enter into the power corona areas with the rotation roller shafts along the rotating feed roller(Grounding Electrode)surface,Corona current makes all the mineral particles(conductors and non-conductors) obtain negative charge,Because of low contact resistance.with the rotating feed roller,the conductor’s charges transfer by the roller away quickly,Under the action of mechanical forces,conductors escape away from the roller,and enter into the mineral hopper(conductors),At the same time,because of higher contact resistance with the rotating feed roller,the non-conductors’charges couldn’t transfer by the roller away as quickly as conductors’,so they are forced in the roller surface owing to the role of electrostatic force,with the rotating feed roller,the non-conductors enter into the back of the roller,and are unloaded under brush,Then they are collected in the excellent hopper(non-conductors),At last the Semiconductor mineral particles or failed to fully discharge the conductor mineral particles enter into the middle hopper(semiconductor mineral particles)

Performance characteristic

With the reasonable structure, advanced technology, convenient operation, complete protection, high degree of automation, safety and reliable, with better separating effect.

Separation of high accuracy, can make the 120 mesh mineral to 2 mm

High degree of automation, to achieve the feeding, heating, speed adjustment, high-pressure discharge, with high security.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Gravity beneficiation process for iron ore

- Iron Ore Roasting and Magnetic Separation Process

- Iron Ore Combined Beneficiation Process

- Gravity combined beneficiation process for black and white tungsten ore

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Radioactive beneficiation and flotation process for uranium ore

- Complete Manganese Ore Gravity Separation Process

Leave a message with your needs or comments

Add comment: