Mica is divided into three major categories

muscovite, biotite, and lithium mica. For mica with an effective area greater than 4cm2. manual selection, scrubbing, and photoelectric sorting methods are generally used. For mica with smaller shards, flotation and wind force gravity separation processes are generally used.

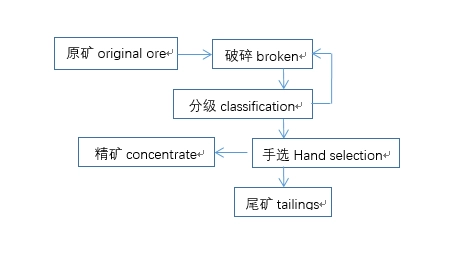

Manual selection process: After crushing and grading the raw ore, it is directly manually selected in the yard or open area to obtain large pieces of mica concentrate.

Process characteristics

low cost, simple process, and low pollution.

Typical beneficiation plant

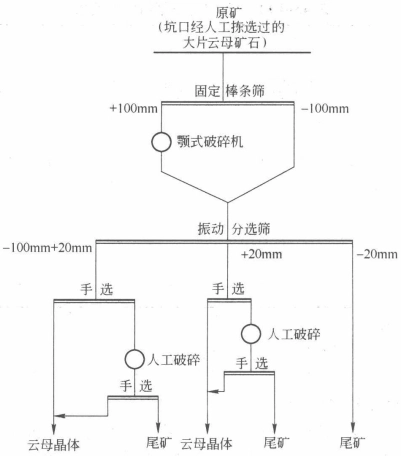

The Danba mica beneficiation plant in Sichuan has good mineralization, large flakes, and easy separation of gangue minerals and mica. By using vibration sorting combined with manual selection, qualified mica concentrate can be obtained.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Copper Ore Partial Mixed Flotation Process

- Carbon leaching beneficiation process for gold mines

- Laterite Nickel Ore Hydrometallurgical Process for Oxide Ore

- Lithium ore reverse flotation process

- Zirconium Ore Processing: Gravity, Magnetic, and Electric Separation

- Copper-Molybdenum Ore Separation & Flotation Process

- Tantalum-Niobium Ore Gravity Separation Methods

Leave a message with your needs or comments

Add comment: