The phosphorus ore classification+flotation process is a process used to treat lightly weathered or unweathered phosphate rock blocks. Phosphate ore is a phosphate ore, which is an important raw material for phosphate fertilizers and phosphate chemical products. The processing of phosphate rock usually includes steps such as crushing, grading, and flotation to improve the content and purity of phosphorus in the phosphate rock.

Flotation is a commonly used physical beneficiation method in phosphate ore processing, which separates useful minerals (such as phosphate) from gangue minerals by adding flotation agents.

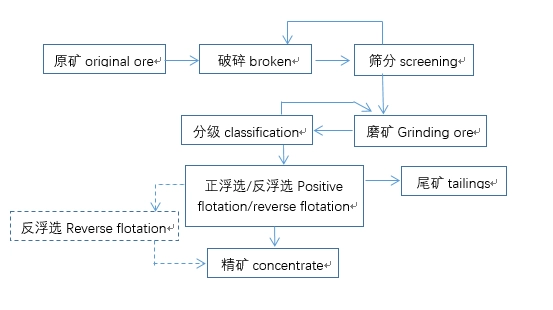

Phosphate ore classification+flotation beneficiation process flow

1.Ore crushing:After crushing the phosphate ore to a certain particle size, it is sent to the flotation machine.

2.Positive flotation process:

The process is to grind the phosphate rock until the monomer is dissociated, add water to adjust the slurry to a certain concentration, use specific collectors to enrich useful phosphate minerals in foam products, and use specific agents to inhibit gangue minerals such as silicate and carbonate in the phosphate rock.

This process is suitable for siliceous or calcium siliceous phosphate rocks, endogenous apatite, and sedimentary phosphate ores. The process flow is simple, the impurity removal effect is good, and it can effectively reduce the content of iron elements. But the energy consumption is high, and the cost of mineral processing is high.

3.Reverse flotation process:

In this process, inorganic acid is generally used to adjust the slurry pH to a certain range (pH=4.0~5.0), and special collectors are used in weak acid medium to enrich dolomite into foam products, and phosphorus minerals are left in the tank. The commonly used flotation reagents are inorganic acid adjusters, modified fatty acid collectors, sulfated fatty acids, or additives added during their saponification process to improve their water solubility, temperature resistance, collection ability, and selectivity.

This process is generally suitable for the separation of phosphorus minerals and dolomite type gangue minerals, with an exclusion rate of up to 70% to 80% for dolomite type gangue minerals. The process does not require heating and can be carried out at low temperature and room temperature, reducing energy consumption and saving costs. However, its applicability is weak, mainly targeting calcareous phosphate ores, and its separation effect on siliceous phosphate ores is poor.

4.First positive and then reverse flotation process:The first positive and then reverse flotation method is mainly used to treat siliceous calcium phosphate ores. First, inorganic alkali is used to adjust the pulp to weak alkalinity. Useful phosphorus minerals are enriched in foam products with specific collectors. Silicate gangue minerals are left in the tank for elimination. foam is the positive flotation concentrate, and then inorganic acid is added to adjust the pulp to weak acidity. After the positive flotation concentrate is adjusted, carbonate impurities are enriched with collectors, and useful phosphorus minerals are left in the tank to obtain the reverse flotation concentrate. The reverse flotation operation is mainly aimed at removing magnesium oxide impurities from phosphorus concentrate.

5.Reverse and then positive flotation method:The sequence of the first reverse and then reverse flotation method is opposite to the first forward and then reverse flotation method. The first stage can grind the ore to a mass fraction of -200 mesh, accounting for 70-80%. Most of the carbonates have already dissociated. The carbonate gangue is first floated using a collector under acidic medium conditions to obtain the reverse flotation concentrate. Then, the second stage is ground until the siliceous gangue dissociates, and phosphorus minerals are floated under alkaline medium conditions to obtain the positive flotation concentrate. The second stage grinding produces a fresh surface, which is more conducive to the separation of phosphorus and silicon. This process is similar to the first positive and then reverse flotation method, with strong adaptability to the raw ore, ideal final concentrate indicators, relatively low acid consumption, but increased alkali consumption. For using phosphoric acid as an inhibitor, it is beneficial to reduce the cost of reagents, but the difficulty of recycling the return water in the beneficiation plant is relatively high.

6.Double reverse flotation process:

This process generally uses inorganic acids to adjust the slurry to weak acidity, using fatty acid collectors to enrich a portion of dolomite like gangue, and then enriching quartz like minerals through fatty amine collectors. The phosphorus minerals in the tank are the final concentrate. The commonly used flotation reagents are inorganic acid regulators, fatty acids, and fatty amine collectors.

This process is mainly suitable for processing mixed phosphorus ores with low content of siliceous gangue and carbonate. Especially for the separation effect of dolomite and quartz vein minerals. It can achieve low and room temperature flotation, with a simple process, low energy consumption, simple reagent system, and fewer types of reagents. However, the amine collector used in this process is a cationic collector, which will produce a sticky foam with poor selectivity, and is more sensitive to slime. If the mud content in the raw ore is large, the desliming operation needs to be increased, which will make the process more complex.

In the process of phosphate ore beneficiation, the selection of process needs to be determined based on the requirements of phosphate concentrate product indicators and the differences in raw ore properties. Therefore, it is recommended to first conduct beneficiation experiments, and scientifically and reasonably customize the process flow and flotation agent system based on the results of beneficiation experiments to ensure the desired beneficiation indicators and economic benefits.

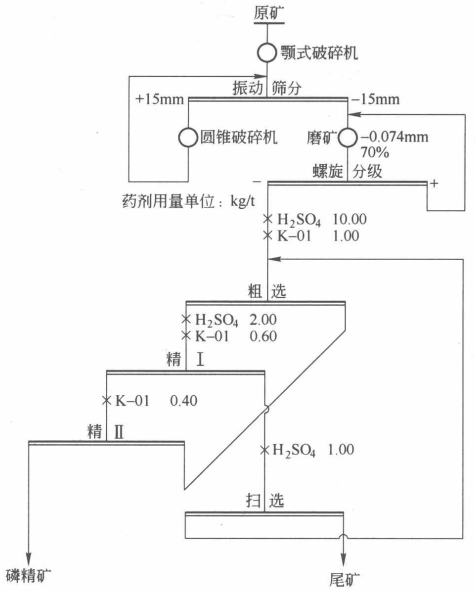

Typical beneficiation plant

Nanzhang Hongxing Phosphate Mineral Processing Plant: The ore is a sedimentary type phosphate rock deposit, with the main phosphorus mineral being collophane and containing a small amount of microcrystalline apatite. The gangue is mainly composed of clay minerals, carbonate minerals, iron and organic matter, etc. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore flotation+gravity separation+magnetic separation process

- Hg-ore flotation process

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Uranium Ore Radioactive Treatment Process

- Zirconium Ore Processing: Gravity, Magnetic, and Flotation Methods

- Chromium Ore Gravity Separation and Flotation Process

- Chromite Gravity, Magnetic, and Electric Separation Process

Leave a message with your needs or comments

Add comment: