The phosphate ore flotation magnetic separation combined process is a process used to treat phosphate ores containing magnetic minerals such as iron and titanium. The main advantage of this process is the high comprehensive utilization rate of resources, which can effectively recover and utilize valuable minerals in phosphate ore.

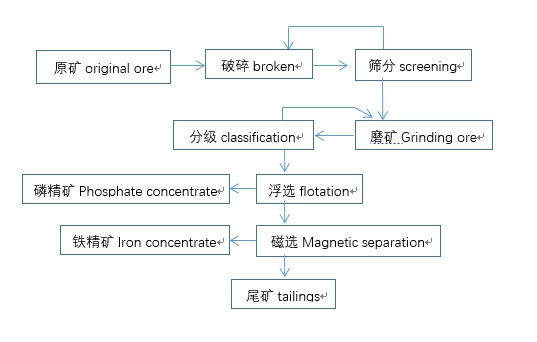

Phosphate ore flotation magnetic separation combined process flow

1.Ore crushing:Crushing phosphate ore to achieve appropriate particle size for subsequent processing.

2.Flotation: The crushed ore is subjected to flotation treatment. During the flotation process, appropriate flotation agents are added to separate valuable minerals (such as magnetite and ilmenite) from phosphate ore and float them onto the surface of the slurry.

3.Magnetic separation: The flotation concentrate is subjected to magnetic separation treatment. During the magnetic separation process, magnetic minerals (such as magnetite and ilmenite) are separated from the concentrate using a magnetic separator.

4.Concentrate processing: Further processing of magnetically separated concentrate, such as concentration and filtration, to improve its purity and quality.

Technological advantages

1.High comprehensive utilization rate of resources:The combined process of phosphate ore flotation magnetic separation can effectively recover and utilize valuable minerals in phosphate ore, improving the comprehensive utilization rate of resources.

2.Reducing environmental pollution: As this process does not require the addition of chemical agents, it reduces environmental pollution.

3.Improving economic benefits: Through the combined process of phosphate ore flotation magnetic separation, higher purity phosphate ore products can be obtained, thereby improving economic benefits.

The combined process of phosphate ore flotation magnetic separation is an effective method for processing phosphate ore, suitable for processing phosphate ore containing magnetic minerals such as iron and titanium. Through this process, the comprehensive utilization rate of resources can be improved, environmental pollution can be reduced, and economic benefits can be improved.

Typical beneficiation plant

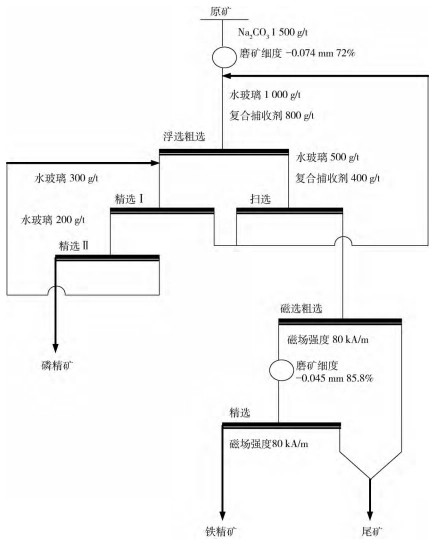

Liaoning iron phosphorus ore: The main phosphorus mineral in the ore is apatite, the recyclable iron mineral is magnetite, and the gangue minerals are mainly feldspar, mica, quartz, etc. Apatite and magnetite are not closely coexisting, and individual dissociation is relatively easy. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore gravity separation+roasting+magnetic separation+gravity beneficiation process

- Iron Ore Combined Beneficiation Process

- Lead zinc ore mixing+separation flotation process

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Lithium ore combined beneficiation process

- Uranium Ore Radioactive Treatment Process

- Zirconium Ore Processing: Gravity, Magnetic, and Flotation Methods

Leave a message with your needs or comments

Add comment: