The phosphate ore roasting+digestion -+classification process is a process used to treat sedimentary calcium phosphate rock deposits that are harder and contain more carbonates. The main advantages of this process are its simplicity, mature equipment, and no need for chemical agents.

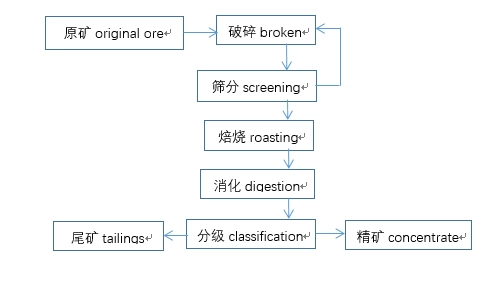

Phosphate ore roasting+digestion+classification process flow

1.Ore crushing:Crushing phosphate rock ore to achieve appropriate particle size for subsequent processing.

2.Roasting:The crushed ore is subjected to roasting treatment. During the roasting process, carbonate minerals (such as calcite) in the ore will decompose, releasing carbon dioxide, making the phosphate minerals in the ore easier to digest and extract.

3.Digestion: Digest the roasted ore. During the digestion process, the ore reacts with the digestion solution (such as dilute sulfuric acid or hydrochloric acid), causing the dissolution of phosphate minerals, while calcium minerals remain insoluble. The digested slurry is filtered and washed to separate the dissolved phosphate.

4.Grading: The digested slurry is graded, such as using a classifier to separate phosphate rocks of different particle sizes. The graded phosphate ore can be further processed as needed, such as concentration, drying, etc.

Technological advantages

1.Simple process: The roasting+digestion+grading process is relatively simple, without the need for complex chemical reactions and chemical additives, making it easy to operate and manage.

2.Mature equipment: The equipment used in this process, such as crushers, roasting furnaces, classifiers, etc., is technically mature and easy to purchase and maintain.

3.No need for chemical agents:Compared with other flotation or dissolution methods, the roasting digestion classification process does not require the addition of chemical agents, thereby reducing environmental pollution and production costs.

The phosphate ore roasting+digestion+classification process is an effective method for processing phosphate ore, suitable for dealing with harder and more carbonate containing sedimentary calcareous phosphate rock deposits. Through this process, high-quality phosphate ore products can be obtained.

Typical examples

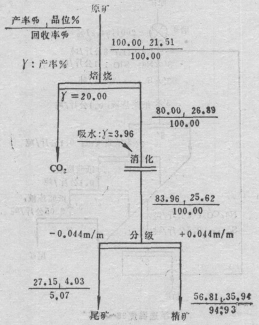

The Datang section of Weng’an phosphate mine: The main useful minerals in the ore are collophane, carbon apatite, and apatite, while the vein minerals are mainly dolomite, calcite, clay minerals, and carbonaceous minerals. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore flotation+gravity separation+magnetic separation process

- Iron ore reverse flotation process

- Iron Ore Roasting and Magnetic Separation Process

- Gold Mine Heap Leaching: Optimal Process

- How to Extract Gold Using Mercury

- Gravity combined beneficiation process for wolframite ore

- Lead-zinc Ore Asynchronous Flotation Process

Leave a message with your needs or comments

Add comment: