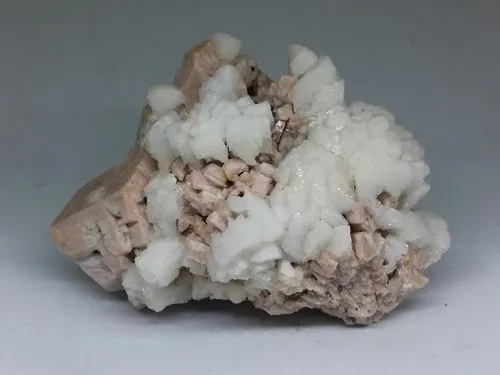

Feldspar is one of the important raw materials in the fields of ceramics, glass, etc. It is widely distributed in nature and can be divided into pegmatite type feldspar and magmatic rock type feldspar according to their genesis. According to the different properties of feldspar deposits, their beneficiation processes and equipment also vary. This article will introduce the beneficiation methods, processes, and equipment of feldspar ore to you!

The beneficiation process flow of pegmatite type feldspar

1.Picking operation:

Hand selection or color selection: In pegmatite type feldspar deposits, large blocks of gangue minerals are first separated by manual selection or color selection. This method can effectively remove the low-quality parts and improve the quality of the ore.

2.Crushing operation:

Coarse crushing and crushing:The selected ore is first subjected to coarse crushing, breaking large pieces of ore into small pieces. Then, the small pieces of ore are further crushed into finer particles.

3.Grinding operations:

Ceramic lining board, quartzite gravel mill or rod mill:Continuous crushing operation is carried out using ceramic lining board or quartzite gravel mill. This grinding method can effectively grind the ore into finer particles for subsequent beneficiation operations.

4.High intensity magnetic separation operation:

Removal of iron and other magnetic minerals:In strong magnetic separation operations, a magnetic separator with a strong magnetic field strength (generally above 1200kA/m) is used to remove iron and other magnetic minerals from the ore. This helps to improve the quality of feldspar products.

Technological advantages

1.Simple and Efficient Process:The beneficiation process of pegmatite type feldspar is relatively simple, from picking to strong magnetic separation, each link can effectively improve the grade and recovery rate of feldspar.

2.Energy conservation and environmental protection:Throughout the entire process, the selection and operation of beneficiation equipment pay attention to energy efficiency ratio, which helps to reduce energy consumption and minimize the impact on the environment.

3.Strong adaptability :The beneficiation process of pegmatite type feldspar can adapt to different qualities and compositions of pegmatite type feldspar ore, with high flexibility and adaptability.

4.Improve product quality:Through strong magnetic separation operation, effectively remove magnetic minerals such as iron, further improve the quality of feldspar products, and meet the needs of different fields for feldspar quality.

The beneficiation process of pegmatite type feldspar has advantages such as simplicity, efficiency, energy conservation and environmental protection, strong adaptability, and improved product quality, providing strong support for the development and utilization of pegmatite type feldspar deposits.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Gold Mine Heap Leaching: Optimal Process

- Gold Mine Gravity Beneficiation Process

- Arsenic Gold Ore Oxidation Roasting Pretreatment Process

- Floatability flotation process for lead-zinc ore

- Lithium ore magnetic separation process

- Uranium Ore Radioactive Treatment Process

- Zirconium Ore Processing: Gravity, Magnetic, and Electric Separation

Leave a message with your needs or comments

Add comment: