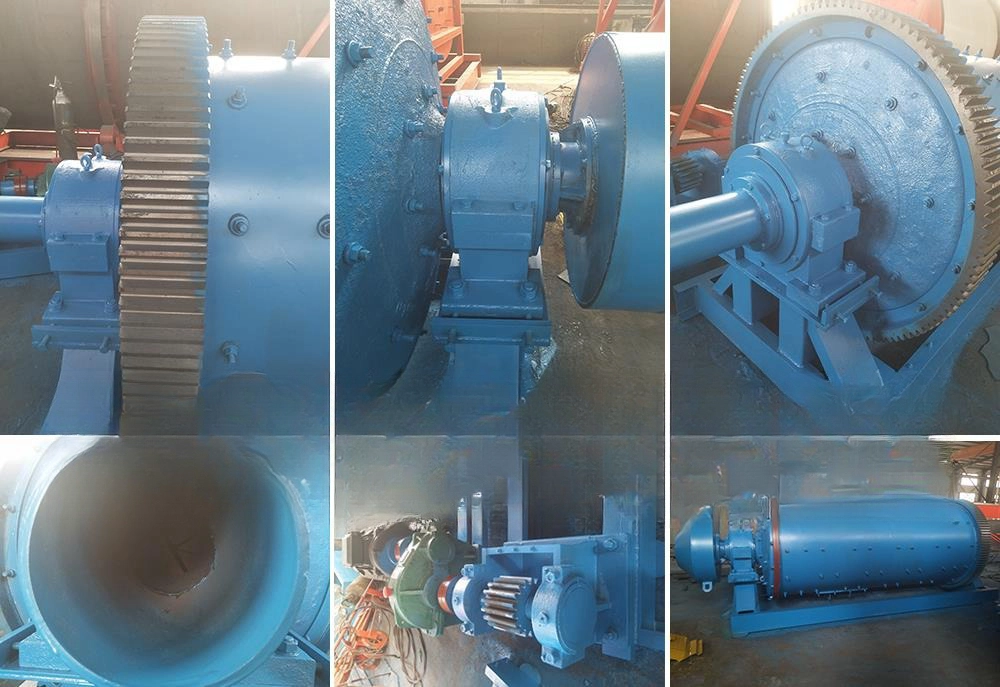

In the field of industrial equipment, ball mills play a vital role in the process of grinding materials. At the heart of the machine are steel balls, which serve as the grinding media. The collision and friction between the steel ball and the material produce ideal grinding effect. However, the efficiency of the ball mill is closely related to the gradation of the grinding steel balls. It is imperative to maintain a reasonable ratio of various steel balls to ensure optimal performance.

The basic principles of ball mill classification revolve around the consideration of ball ratio. This ratio is a key factor in determining the efficiency of the grinding process. By ensuring a certain ratio of steel balls, the equipment can effectively adapt to the particle size composition of the materials to be ground, and ultimately achieve excellent grinding results.

When it comes to ball mill operation, maintaining ball ratio is an important consideration. The process of adding steel balls to a ball mill requires careful attention to detail. It is crucial to add the steel balls in a specific order and quantity to maintain the desired proportions. This meticulous approach is critical to the smooth operation of the equipment and the quality of the grinding process.

In addition to the consideration of maintaining the steel ball ratio, there are some specific precautions that need to be taken during the ball mill ball grading process. The grading process is critical to ensuring that the steel balls are properly sized and distributed within the equipment. This careful grading is critical to achieving the desired grinding results and maximizing the efficiency of the ball mill.

summary

the role of steel balls in ball mill equipment cannot be overemphasized. Careful consideration of the steel ball ratio and the careful ball addition and grading process are crucial to ensuring that the ball mill operates efficiently and achieves optimal grinding results. By adhering to these principles and precautions, industries can maximize the performance of their ball mill equipment and enhance the overall production process.

- Random article

- Popular articles

- Popular comments

- Stepwise priority flotation process for copper ore

- Hg-ore Gravity selection+flotation process

- Sand gold beneficiation process

- Cyanide Gold Preparation

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

Leave a message with your needs or comments

Add comment: