Gold Mine Pit Leaching

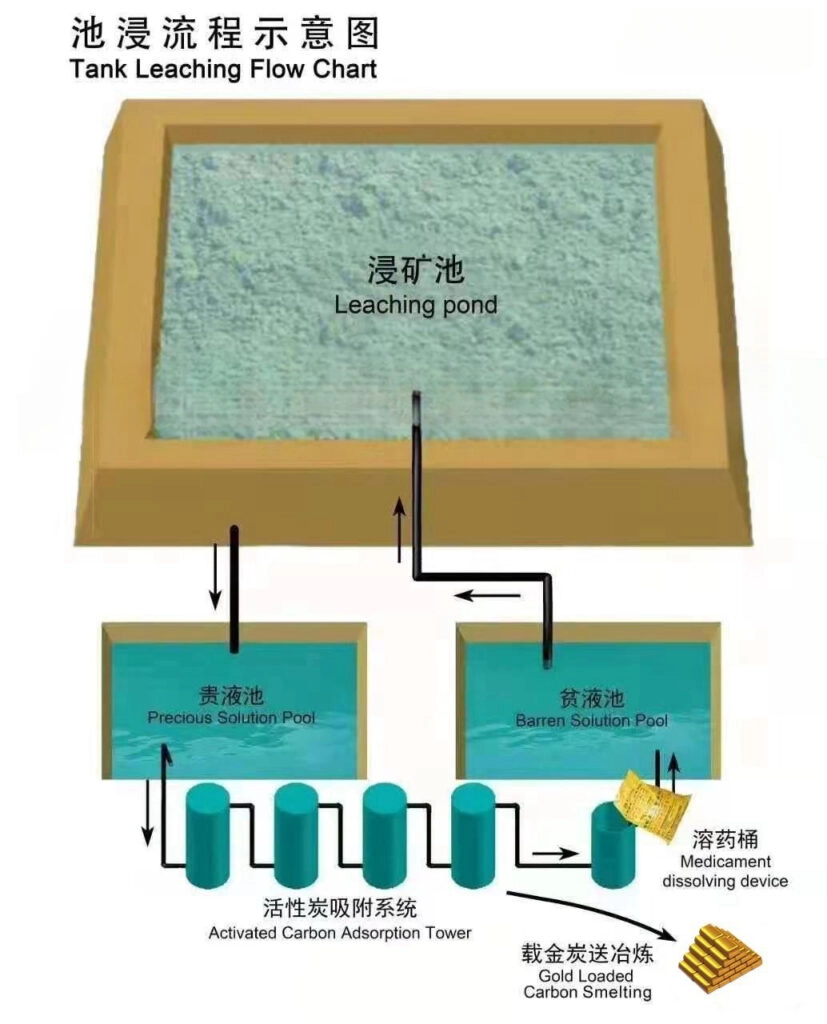

Leaching, a common process in mining and metallurgy, typically takes place in a leaching pit constructed from materials such as wood, iron, or cement. These pits are designed with a horizontal or slightly inclined bottom, and can come in various shapes including circular, rectangular, or square. To facilitate the leaching process, the pit is fitted with a false bottom made of porous acid-resistant plates, which is then covered with filter cloth and a grille composed of wooden boards or corrosion-resistant metal strips.

In the leaching operation, the ore is loaded into the pit, and the leaching agent is introduced from above. As the leaching agent permeates through the ore, the resulting leachate flows out from the bottom of the false bottom. This crucial component serves the dual purpose of filtering the leachate and providing support for the ore during the leaching process.

The use of leaching pits is integral to the extraction of valuable minerals from ores, as it allows for the efficient separation of desired components from the raw material. The design and construction of these pits are tailored to withstand the corrosive nature of the leaching agents and the abrasive characteristics of the ore. Additionally, the incorporation of the false bottom with its filtering and supporting functions ensures the smooth progression of the leaching process.

summary

leaching pits play a vital role in the extraction of metals and minerals, providing a controlled environment for the interaction between the leaching agent and the ore. The careful engineering and implementation of these pits are essential for maximizing the efficiency and effectiveness of the leaching process in various industrial applications.

- Random article

- Popular articles

- Popular comments

- Hg-ore Gravity selection+flotation process

- Intense Magnetic Separation Process for Iron Ore

- Iron ore reverse flotation process

- Uranium Ore Radioactive Treatment Process

- Zirconium Ore Processing: Gravity, Magnetic, and Flotation Methods

- Effective Gravity Beneficiation for Chromium Ore

- Chromite Gravity and Magnetic Separation Process

Leave a message with your needs or comments

Add comment: