Description

Name: mixing tank, chemical mixing tanks, stainless mixing tanks, industrial mixers

Product use: mixing and mixing pulp Product material: conventional manganese steel, can be customized

Motor power: 5.5kw

Feed particle size: 1-100mm

Processing capacity: 3-800T/h

Stirrer diameter: 240-850mm

Effective volume: 0.26-30m³

Structure: right-angle blowing valve, reducer coupling, motor, beam bracket, stirring impeller, main shaft, circulation (barrel) tank and other structures.

Working Principle

Mixing drums are necessary to enable rotation of the impeller driven by the motor V-belt in order to mix the medicine and pulp evenly, as well as to speed up the reaction time of the medicine and strengthen the quality of its reaction. The mixing tank is suitable for mixing all types of metal ores, mainly used for mixing before flotation. The stirrer is designed to stir pulp whose concentration does not exceed 30%, whose density does not exceed 3.5. and whose particle size is not greater than 1mm.

Mixing tank is widely used in mining field, especially in concentrator. It is one of the commonly used equipment.

1. Effect of Mixing

There are generally five purposes of mixing;

(1) Mixing two or more liquids to obtain a uniform mixture;

(2) Mixing and dispersing two or more immiscible liquids to obtain emulsion;

(3) Mixed gas and solution;

(4) Suspend solid particles in solution;

(5) Accelerate chemical reaction, heat and mass transfer, etc.

Mixing is an essential step in metal and non-metal beneficiation, hydrometallurgy, rare and precious metal leaching and extraction.

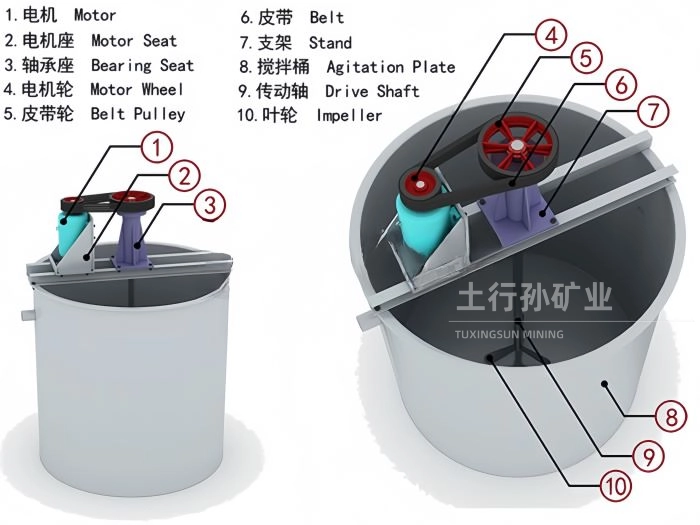

2. Structure of mixing tank

The mixing tank is mainly composed of the following parts:

(1) The container containing the stirred slurry, namely the mixing tank;

(2) The main shaft part is a rotating vertical shaft with agitator (mixing wheel)

(3) Motor and transmission device (divided into belt transmission and reducer transmission);

(4) Auxiliary components, including support beam, feed and discharge pipe, baffle on the wall of diversion and rectification circulating device (circulating cylinder), etc.

| Model | Effective Volume (m3) | Rotating Speed of Impeller (r/min) | Diameter of Impeller (mm) | Motor Model | Motor Power(kW) | Weight(kg) |

| RJ05 | 0.078 | 690 | 150 | Y80M2-4 | 0.75 | 110 |

| RJ07 | 0.26 | 530 | 240 | Y90L-4 | 1.5 | 228 |

| RJ10 | 0.58 | 530 | 240 | Y90L-4 | 1.5 | 350 |

| RJ12 | 1.14 | 320 | 400 | Y132S-6 | 3 | 765 |

| RJ15 | 2.2 | 320 | 400 | Y132S-6 | 3 | 1360 |

| RJ20 | 5.5 | 230 | 550 | Y132M2-6 | 5.5 | 1655 |

| RJ25 | 11 | 230 | 625 | Y160M-6 | 7.5 | 2766 |

| RJ30 | 19.1 | 210 | 900 | Y225S-8 | 18.5 | 4296 |

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Copper ore oxidation-reduction segregation+flotation process

- Intense Magnetic Separation Process for Iron Ore

- Gold selection process using resin slurry method

- Cyanide Gold Preparation

- Floatability flotation process for lead-zinc ore

- Laterite Nickel Ore: Pyrometallurgical Treatment

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

Leave a message with your needs or comments

Add comment: