Description

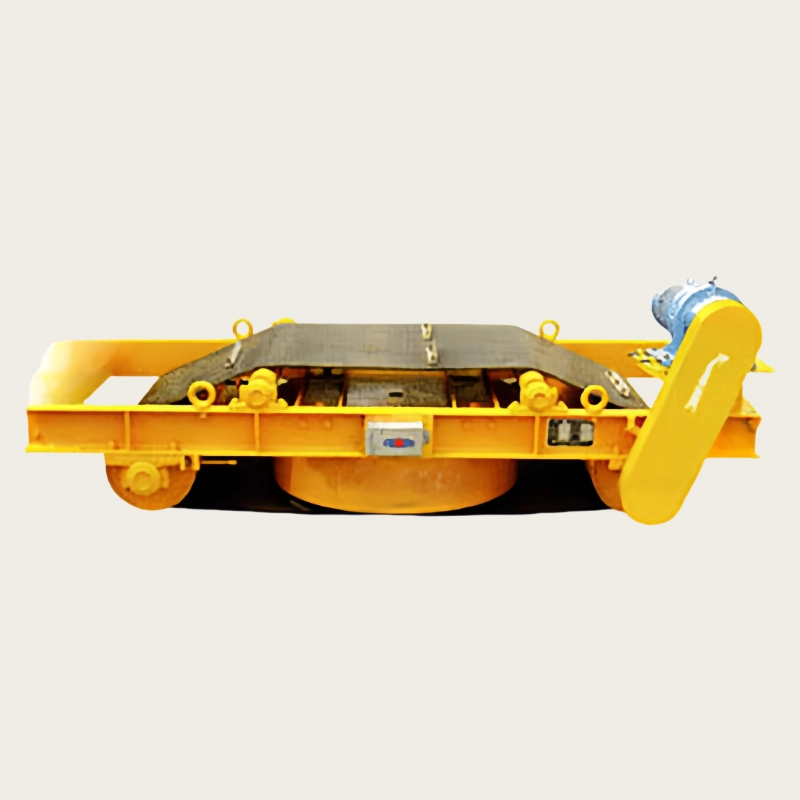

Name: Self-unloading permanent magnet iron remover, Permanent magnet separator

Adaptable bandwidth: 500~2400mm

Magnetic field strength: 50mt~150mt

Motor power: 1.5~7.5kw

Iron removal weight: 0.1~35kg

Dry and wet type: dry iron remover

Equipment model: RCYD series

Scope of application: The process is used to remove iron from any material before the crusher and on the conveyor belt, and can be applied in harsh environmental conditions.

Structure: Mainly composed of frame, cycloidal pinwheel reducer, chain, sprocket, roller, and steel belt with a scraper.

This self-unloading electromagnetic iron remover (Permanent magnet separator)is based on the RCYD series electromagnetic iron remover and contains an automatic iron-displacing mechanism. It has a high iron content, corrosion resistance, continuous work, and can automatically unload iron without power loss. It is mainly used for materials with high iron content. After the ferromagnetic substance is adsorbed, the ferromagnetic substance is discharged from the iron remover through the iron unloading mechanism to achieve automatic iron removal.

Combined with belt conveyors, vibrating conveyors, and other equipment, these products can effectively remove ferro-magnetic substances mixed in bulk materials with a weight of 0.1-30kg. In addition to improving and purifying raw materials, it can also be used to recover various ferromagnetic substances, which protect mechanical equipment such as grinders and crushers from damage and wear.

Working principle

Approximately 0.1-0.36 kg of ferromagnetic impurities mixed in the granular material will be sucked up by the self-unloading permanent magnet iron remover when it passes directly over it. Whenever the magnetic material passes through the non-magnetic area, it is scraped off with the iron parts on the belt and thrown into the iron collecting box, which achieves the purpose of continuous automatic iron removal.

Advantage

1.By using computer simultion, the circuit is designed with a perfect double magnetic pole structure, high magnetic field strength, large gradient, and high suction force.

2.With the high-performance NdFeB magnetic source, the magnetic energy product is high, it is hard to demagnetize, and the demagnetization doesn’t exceed 5% after eight years.

3.With its waist drum type drum structure, automatic deviation correction, fully sealed bearing seat, and good sealing performance, this drum can withstand harsh environments.

4.By automatically unloading iron, the belt can maintain continuous operation over a long period of time without requiring any maintenance.

5.Interlocking the control part with the belt conveyor allows for on-site hands-on operation and centralized control.

| Model | Adaptive bandwidth (mm) | Rated lifting heighth (mm) | Material thickness (≤mm) | magnetic field intensity (≥mT) | Driving power (≤KW) | weight (kg) | Overall dimension (mm) |

| RCYD(C)-5 | 500 | 150 | 80 | 60 | 1.5 | 750 | 1900*735*935*753*950 |

| RCYD(C)-6 | 600 | 175 | 120 | 60 | 1.5 | 920 | 2050*780*1030*753*1100 |

| RCYD(C)-6.5 | 650 | 200 | 150 | 70 | 2.2 | 1200 | 2165*780*1080*888*1200 |

| RCYD(C)-8 | 800 | 250 | 200 | 70 | 2.2 | 1400 | 2350*786*1280*1088*1300 |

| RCYD(C)-10 | 1000 | 300 | 250 | 70 | 3.0 | 2120 | 2660*920*1550*1335*1400 |

| RCYD(C)-12 | 1200 | 350 | 300 | 70 | 4.0 | 3350 | 2900*970*1720*1515*1550 |

| RCYD(C)-14 | 1400 | 400 | 350 | 70 | 4.0 | 4450 | 3225*1050*1980*1775*1800 |

| RCYD(C)-16 | 1600 | 450 | 400 | 70 | 5.5 | 6200 | 3420*1180*2210*1850*1950 |

| RCYD(C)-18 | 1800 | 500 | 450 | 72 | 7.5 | 8100 | 3580*1210*2450*2130*2200 |

| RCYD(C)-20 | 2000 | 550 | 500 | 72 | 11 | 9700 | 3800*1300*2700*2410*2400 |

Note

(1) This device’s magnetic intensity is higher than the national standard T1. T2. T3 magnetic field, the magnetic intensity ratings were hanging above 90mT, 120mT, 150mT.

(2) The equipment for each model size can be made according to specific user needs.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Copper ore stage grinding and selection process

- Copper ore mixed flotation process

- Copper Ore Flotation and Wet Beneficiation Process

- Intense Magnetic Separation Process for Iron Ore

- How to Extract Gold Using Mercury

- Gravity combined beneficiation process for black and white tungsten ore

- Lithium ore heavy medium beneficiation process

Leave a message with your needs or comments

Add comment: