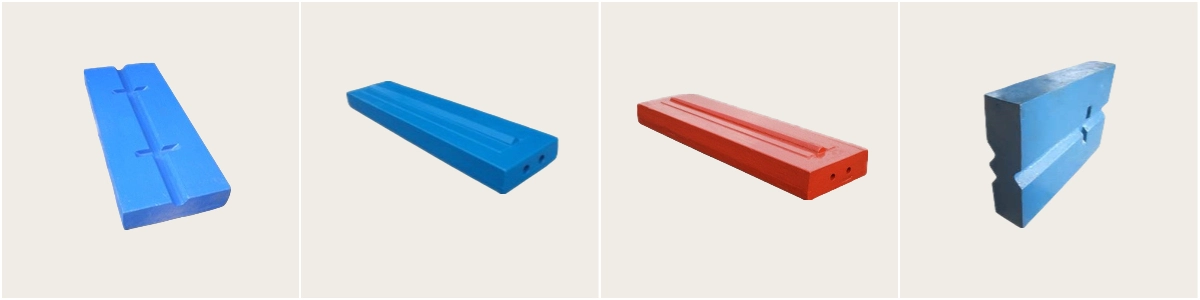

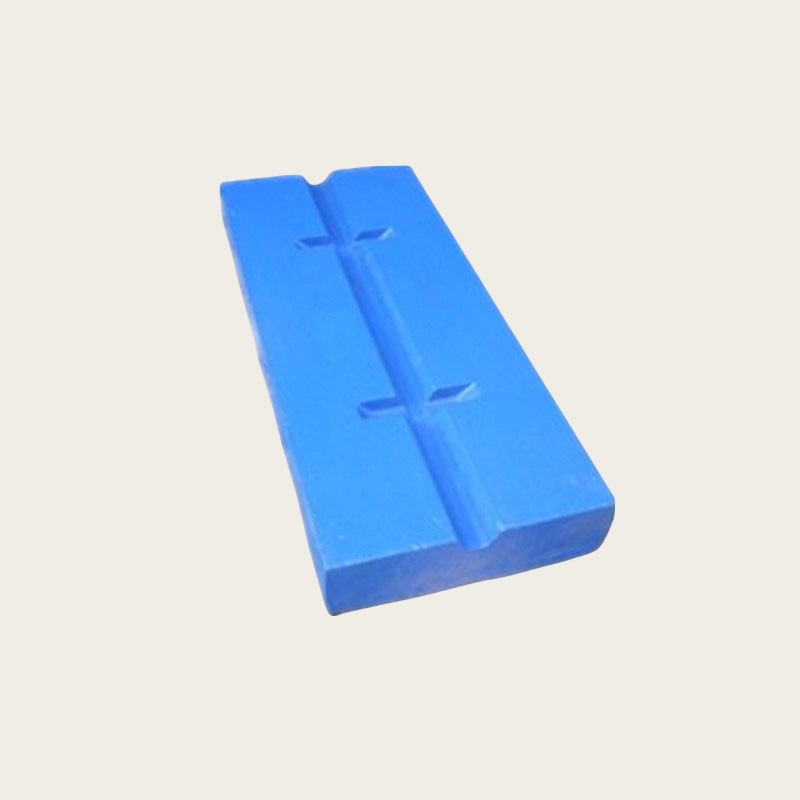

Impact Crusher Blow Bars are applied to impact crusher and mainly for crushing iron ores,granite,quartzite,pebble and other hard or corrosive materials.The product comprises of new wear-resistant materials and rare earth elements.

Material:Cr15Mn2.Cr20Mn2.Cr26Mn2

Molding Process:Water-glass sand casting or lost form casting

Melting facility:Medium frequency electric furnace

Heat Treatment:Anneal, quenching, tempering

1.Introduction of Impact Crusher Blow Bars

Blow bars,also known as back-breaking hammer,is applied to impact crusher and mainly for crushing iron ores,granite,quartzite,pebble and other hard or corrosive materials.The product comprises of new wear-resistant materials and rare earth elements.The material formula is adjusted and improved based on the user’s working conditions according to the exploration by technical personnel on site so as to enable the product having good wear resistance,impact resistance,safety and reliability.Validated by the customer’ use experience,its wear-resistance service life is 1.5-2 times of that of similar products.

2.Production Details of Impact Crusher Blow Bars

High chrome blow bars: while casting, we not only add molybdenum, vanadium, titanium, nickel, boron and other rare alloy elements. Meantime, we specially adopt variety of alloy modifier to strengthen the matrix. Those blow bars use refining, vacuum casting, directional solid and etc technical’s’ to increase the grain refinement and make the hammers performance achieve the best performance.

| Material | C | Cr | Mn | Si | S | P |

| Cr15 | 2.8-3.2 | 13-15 | ≤2 | ≤1.2 | ≤0.06 | ≤0.06 |

| Cr20 | 2.8-3.2 | 18-22 | ≤2 | ≤1.2 | ≤0.06 | ≤0.06 |

| Cr26 | 2.8-3.2 | 24-26 | ≤2 | ≤1.2 | ≤0.06 | ≤0.06 |

We can provide customized design according to our clients’ demands and also refine our products by our clients’ feedback.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- How to Extract Gold Using Mercury

- Gold Ore Carbon Slurry Beneficiation Process

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Lithium ore combined beneficiation process

- Chromite Processing: Gravity, Magnetic, and Flotation Separation

- Titanium Ore Processing: Gravity, Magnetic, Flotation, Electric Separation

- Essential Guide to Tantalum-Niobium Ore Flotation Process

Leave a message with your needs or comments

Add comment: