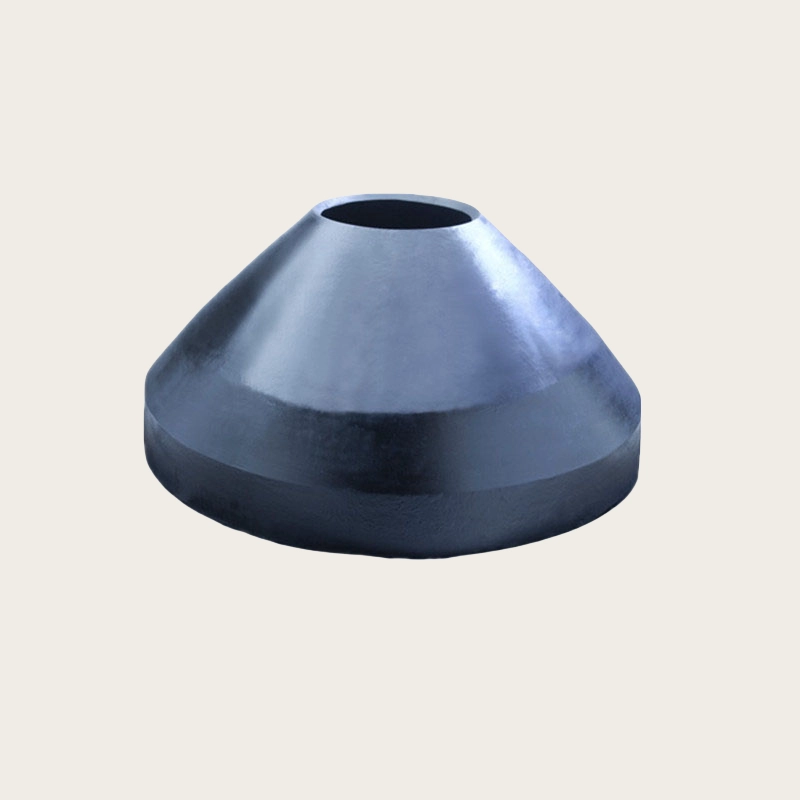

Mantle liner is made or high manganese, wear parts, anti abrasive, used for cone crusher HP/MP/GP-H/CH/S/CS series.

Model: HP/MP/GP-H/CH/S/CS series wear part

Material: high manganese steel

Specification: Metso/Sandvik HP/MP/GP-H/CH/S/CS series cone crusher replacement component.

1.Product Introduction

Mantle liner is made or high manganese, wear parts, anti abrasive, used for cone crusher HP/MP/GP-H/CH/S/CS series.

Model: HP/MP/GP-H/CH/S/CS series wear part

Type: wear part

Material: high manganese steel

Color: customization

Manufacturing origin:CHINA

Specification: Metso/Sandvik HP/MP/GP-H/CH/S/CS series cone crusher replacement component.

2.Features

2.1.Material: high manganese steel: Mn13%, Mn18%, Mn24%.

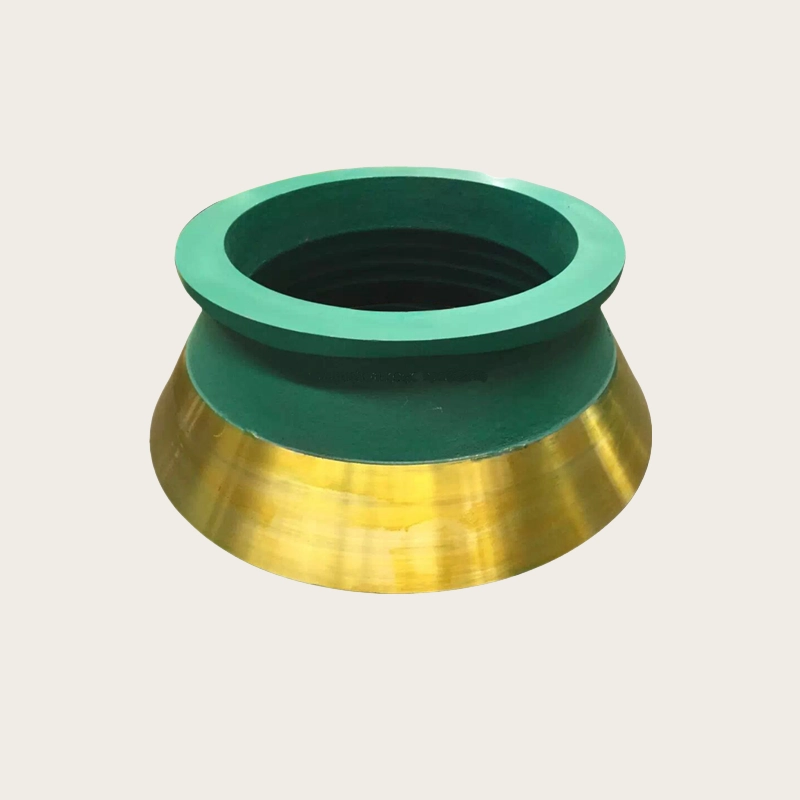

2.2.Use: Machinery in metal recovery smash, mine, metallurgy, chemical industry,cement, petroleum etc.

2.3.Production quality testing: High frequency infrared carbon & sulfur analyzer, Metallographic microscope, Machinery performance testing equipment, Hardness testing equipment, Ultrasonic inspection equipment.

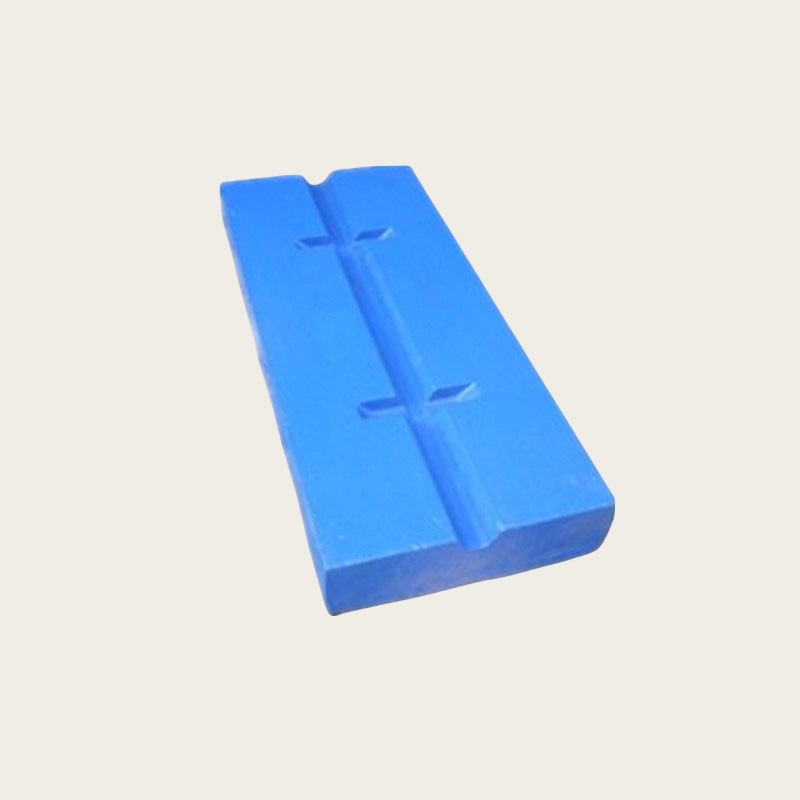

2.4.Easy installation: The anti-abrasion block is a semi-permanent part, which is easy for replacement.

3.Material Specifications of High manganese mantle liner

| Material Code | C | Mn | Si | Cr | Mo | P | S |

| ZGMn13-1 | 1.0-1.45 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-2 | 0.90-1.35 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-3 | 0.9-1.35 | 11.0-14.0 | 0.30-0.8 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-4 | 0.9-1.30 | 11.0-14.0 | 0.30-0.8 | 1.50-2.0 | - | ≤0.09 | ≤0.04 |

| ZGMn13-5 | 0.75-1.30 | 11.0-14.0 | 0.30-1.0 | - | 0.90-1.2 | ≤0.09 | ≤0.04 |

4.Product related information

HP200/HP300/HP400/HP500 /HP800 /MP800/MP1000/MP1250/GP11/GP100/GP200/GP300/GP600/H2000/H3000/H4000/H6000/H8000/H2800/

H4800/H6800/H7800/H8800/CH400/CH430/CH440/CH660/CH870/CH880/CH890/CH895/CH880/S2000/S3000/S4000/S6000/S3800/S4800/S6800/

CS420/CS430/CS440/CS660 cone crusher mantle liners

Spare part product related information:

Cone crusher main frame liners

Cone crusher mantle liners

Cone crusher bowl liners

Cone crusher arm guards

Cone crusher protection cones

We can provide customized design according to our clients’ demands and also refine our products by our clients’ feedback.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Iron Ore Roasting and Magnetic Separation Process

- Gravity combined beneficiation process for wolframite ore

- Lithium ore heavy medium beneficiation process

- Zirconium Ore Processing: Gravity, Magnetic, and Flotation Methods

- Basic techniques for antimony ore flotation processing

- Polymetallic Molybdenum Ore Processing: Magnetic Separation and Flotation

- Rutile Processing: Gravity, Magnetic, Flotation, Electric Separation

Leave a message with your needs or comments

Add comment: