The gold heap leaching process is a widely used technology for gold extraction from ores, favored by the industry due to its low production costs, simple operation, and flexible scalability. However, this process also faces some challenges and issues in practical operations. This article will provide a detailed overview of the gold heap leaching process and discuss common problems and their solutions.

01 Overview of Heap Leaching Process

What is the Gold Heap Leaching Process?

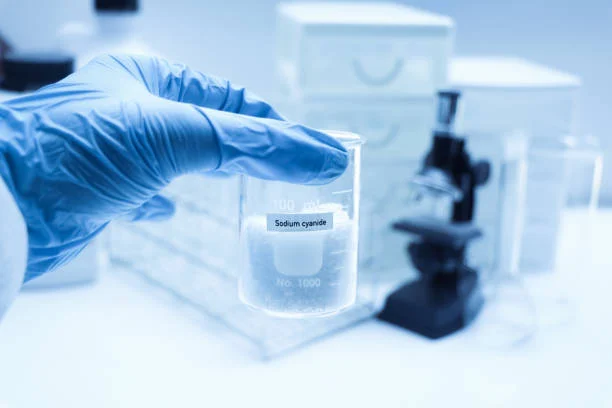

The gold heap leaching process involves crushing ores to a certain particle size, piling them on a specific site, and leaching them with a cyanide solution through spraying or percolation. This method extracts metals by allowing the solution to come into contact with the ores. It is widely adopted due to its simplicity, low cost, and applicability to low-grade ores.

Areas of Application for Heap Leaching Process

The gold heap leaching process is primarily used for gold extraction from gold ores and is also suitable for the extraction of other metal ores such as copper, silver, and uranium. This process is not only applicable to newly mined ores but can also be used for the reuse of waste ores or tailings, improving resource utilization.

Environmental Impact of Heap Leaching

Although economically efficient, the heap leaching process poses potential environmental risks, such as the leakage of chemical reagents, soil and groundwater contamination, etc. Therefore, effective environmental protection measures must be taken when implementing the heap leaching process to ensure that the surrounding ecological environment is not damaged.

02 Common Issues and Solutions in the Gold Heap Leaching Process

(1) Low Heap Leaching Efficiency

Factors Affecting Heap Leaching Efficiency

Heap leaching efficiency is influenced by several factors, such as ore particle size, uniformity of leaching solution spraying, porosity of the ore, and the flowability of the leaching solution, all of which play a crucial role in the leaching process.

Methods to Improve Heap Leaching Efficiency

To improve heap leaching efficiency, one can optimize the ore crushing particle size to ensure uniformity and improve the spraying system design to ensure uniform coverage of the leaching solution, thereby increasing the leaching speed.

(2) Low Metal Recovery Rate During the Leaching Process

Reasons for Low Recovery Rate

A low metal recovery rate is usually due to insufficient reaction between the solution and minerals, insufficient leaching time, or complex mineral properties.

Technologies to Improve Recovery Rate

To improve the metal recovery rate, one can use more efficient leaching agents, extend the leaching time, or adopt advanced technologies such as stirred leaching to promote the complete dissolution of metals in the ore.

(3) Leaching Solution Seepage Issues

Analysis of Seepage Causes

Seepage of leaching solution can occur due to improper laying of a waterproof layer at the leaching site, improper foundation treatment, or excessive pressure from the flow of leaching solution.

Measures to Effectively Prevent Seepage

Measures to prevent seepage include: laying geosynthetic membranes or other waterproof materials on the foundation of the leaching site, strengthening the foundation treatment of the site, and regularly inspecting the stability of the leaching area to ensure there are no seepage risks.

(4) Environmental Pollution During the Leaching Process

Common Pollution Issues

Environmental pollution is mainly manifested in the infiltration of harmful substances from the leaching solution into the soil and groundwater, especially cyanide and heavy metal pollution, posing a threat to the ecosystem and human health.

Feasible Environmental Protection Measures

Using a closed-loop system to recycle and reuse the leaching solution; setting up seepage detection and emergency response systems; and using more environmentally friendly leaching agents, such as bio-leaching or ammonia leaching, can effectively reduce environmental pollution.

(5) Excessive Heap Leaching Cycle Time

Reasons for Long Cycle Time

Long heap leaching cycles are often caused by difficult leaching of ores, slow reaction rates, or limitations of site and equipment conditions.

Technologies to Shorten the Leaching Cycle

The leaching cycle can be shortened by increasing the fine grinding particle size of the ore to accelerate the reaction rate, or by applying efficient leaching reagents. Additionally, adding stirring or increasing the reaction temperature can also help speed up the leaching process.

(6) Inhomogeneous Heap Leaching Material Particle Size

Impact of Material Particle Size on Heap Leaching

Inhomogeneous particle size can lead to poor flow of leaching solution, thereby reducing leaching efficiency. Uneven particle size may also cause agglomeration of the ore pile, affecting the contact area for the reaction.

Methods to Control Material Particle Size

The key to controlling material particle size is to optimize the crushing and screening process to ensure uniform particle size. Regular inspection and maintenance of screening equipment are necessary to ensure effective screening.

(7) Unstable pH Value of the Leaching Solution

Reasons for pH Instability

The pH value of the solution during the leaching process can be affected by various factors such as temperature, mineral chemical properties, and the concentration of leaching agents, leading to instability.

Methods to Maintain Stable Solution pH

By regularly monitoring the pH value and adjusting the acidity or alkalinity of the solution with acid or alkali; choosing appropriate buffering solutions to maintain stable pH, ensuring the continuity and consistency of the leaching process.

(8) Inhomogeneity in Heap Leaching Temperature

Impact of Temperature Variation on Heap Leaching

Inhomogeneity in temperature can affect the rate of chemical reactions and leaching efficiency, especially in cold climates, where low temperatures can significantly slow down the reactions.

Measures to Maintain Uniform Temperature

Covering with insulation layers or heating the surrounding area of the leaching site can maintain the uniformity of the leaching temperature. Additionally, using heating devices or solar thermal facilities can also ensure stable temperature.

(9) Improper Selection of Heap Leaching Sites

Key Factors in Site Selection

Site selection should consider factors such as terrain, convenience of transportation, environmental impact, and infrastructure to ensure the smooth implementation of the leaching process.

Methods to Optimize Site Selection

Choose areas with convenient transportation, relatively flat terrain, and good drainage conditions. Conduct detailed surveys and geological investigations to avoid environmentally sensitive areas.

(10) Wear and Tear of Heap Leaching Equipment

Reasons for Equipment Wear

Heap leaching equipment works in a highly corrosive environment for a long time and frequently comes into contact with chemical reagents and ores, making it susceptible to wear and erosion.

Maintenance Methods to Extend Equipment Life

Regularly inspect the working condition of the equipment and replace worn parts in a timely manner; use equipment made of corrosion-resistant materials; and apply lubricants and preservatives to reduce equipment wear.

03 Future Development Trends of Heap Leaching Process

Application of New Technologies in Heap Leaching Process

In the future, the gold heap leaching process will increasingly integrate nanotechnology, biotechnology, and molecular sieve technology to improve the leaching efficiency and metal recovery rate of ores.

Development Direction of Environmentally Friendly Heap Leaching Process

The focus of the development of environmentally friendly heap leaching processes is to reduce the use of cyanide and develop the use of green and environmentally friendly leaching agents, such as bio-leaching and plant leaching technology.

Prospects of Automation and Intelligence in Heap Leaching Process

Automation and intelligent technologies will be widely applied in the monitoring, control, and management of heap leaching processes, improving operational efficiency, reducing labor costs, and achieving intelligent management.

By addressing the aforementioned common issues, optimizing process flows, and introducing new technologies, the gold heap leaching process will continue to play an important role in the field of gold extraction from ores and develop towards being more efficient, environmentally friendly, and intelligent.

- Random article

- Popular articles

- Popular comments

- Positive flotation beneficiation process for bauxite

- Gold Mine Combined Beneficiation Process

- Cyanide Gold Preparation

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Lithium ore combined beneficiation process

- Zirconium Ore Separation: Gravity and Magnetic Methods

- Zirconium Ore Processing: Gravity, Magnetic, and Electric Separation

Leave a message with your needs or comments

Add comment: