Because sulfide ore accounts for 87% of the copper ore that has been mined, the separation of copper and sulfide is an important part of recovering copper metal. How to achieve the extraction of copper from sulfide ore? This article will tell you 5 methods!

Single Flotation

Mixed-priority Flotation

Partial Mixed Flotation

Direct Priority Flotation

Separation of Mud and Sand-Flotation

![Copper Extraction from Sulfide Ore Flotation machines copper sulfide polymetallic ores machinery manufacturing sales solutions exports 第1张 Copper Extraction from Sulfide Ore Flotation machines copper sulfide polymetallic ores machinery manufacturing sales solutions exports 第1张]()

01Type of copper sulfide ore

Before learning about the beneficiation flow, you need to know, according to the structure of the ore, copper sulfide ore can be divided into the following two types: one is dense massive copper sulfide ore, and the other is disseminated copper sulfide ore. For the difference in the two type of ore, the extraction of copper from sulfide is also different.

The dense massive copper sulfide ore has a high content of pyrite and less gangue. Its characteristic is that the aggregate of pyrite and copper minerals is dense without voids. So, this type of ore generally adopts the preferential flotation process: Inhibit sulfide and give priority to flotation of copper, and the tailings are sulfide concentrates; or when the content of gangue is high, you will also need to extract sulfide from the tailings.

The content of copper and sulfide in the disseminated copper-sulfide ore is low, the copper-sulfide ratio is relatively large, and the ore generally contains 10%-40% pyrite. The gangue is unevenly infiltrated with copper minerals and pyrite, and some pyrites closely co-exist with copper minerals, and the aggregates have large particle sizes. For such ores, the beneficiation process of copper and sulfide mixed flotation-copper and sulfide mixed concentrate regrind and separation is generally adopted.

02Extraction method of copper sulfide ore

Understanding the feature of these two types of copper sulfide ore, you can know that the extraction of copper from sulfide ore is essentially a process of separating copper sulfide and iron sulfide. Therefore, the method of extraction of copper from sulfide ore is as follows:

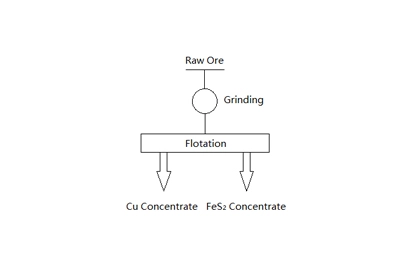

1. Single Flotation

The dense massive copper-sulfide ore has few gangues, so it can be regarded as a copper-sulfide mixed concentrate. In addition, pyrite occupies the majority, so only flotation is required. The specific steps are to add a large amount of lime to suppress the pyrite first, give priority to extracting the copper from sulfide ore, and the tailings obtained can be used as qualified Sulphur concentrate. The flotation process is shown in the figure below.

(single flotation of copper-sulfide ore)

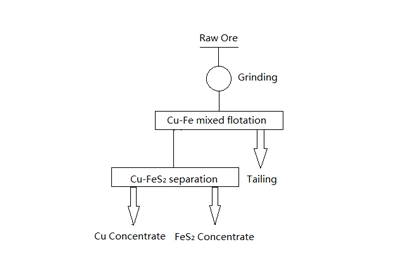

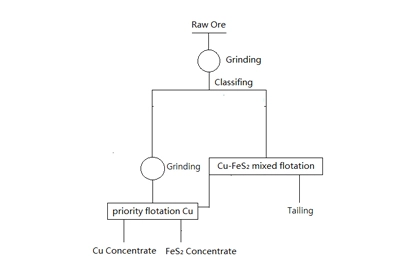

2. Mixed-priority flotation

The mixed-priority flotation process is suitable for the extraction of copper from dense massive sulfide ore and disseminated sulfide ore with a non-sulfide content of more than 10-15%. The process flow is shown in the figure below. Most of the gangue is discarded in the mixed flotation circuit, so the copper concentrate grade can be improved.

(mixed-priority flotation of copper-sulfide ore)

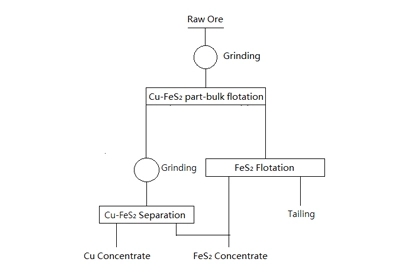

3. Partial mixed flotation

Some concentrators use the partial mixed flotation process to achieve the extraction of copper from sulfide ore, that is, to reduce the pH value of the ore pulp during roughing, so that the conjoined body of copper minerals and pyrite enters the foam product to get concentrate. And then the concentrate is reground and separated to get copper concentrate and iron concentrate. The tailings get is Sulphur concentrate The process flow is shown in the figure below.

(partial mixed flotation of copper-sulfide ore)

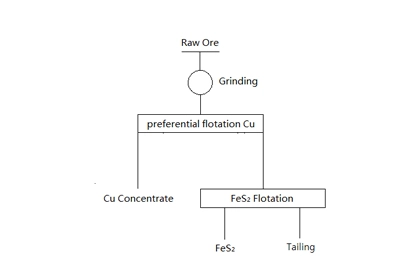

4. Direct priority flotation

The direct priority flotation process is adopted to extract copper from disseminated sulfide ore, and the process flow is shown in the figure below. Because the amount of inhibitor used in copper extraction is small, only a small amount of activator is needed when separating sulfur, and sulfur can be extracted even without adding activator.

(direct priority flotation of copper-sulfide ore)

5. Separation of mud and sand-flotation

Some concentrators will use a sand separation process to achieve the extraction of copper from sulfide ore. After the ore is ground and classified, the mud and sand are flotated separately. Most of the gangue enters the fine mud part and becomes waste tailings in the flotation process. The flotation foam of the sludge and the finely ground ore are combined. And then extract copper from it. The tailings are the sulphur concentrate. This process improves the flotation of coarse sand circuit and can separate flotation sludge under suitable conditions. The process is shown in the figure below.

(separation of mud and sand-Flotation of copper-sulfide ore)

03To Wrap Up

The above are 5 common processes for extracting copper from sulfide ore. It can be seen that in copper-sulfide ore, pyrite is one of the main components, and it is almost always inhibited and separated from other minerals. Therefore, the flotation of pyrite has an important influence on the entire beneficiation process. In addition, before the extraction of copper from sulfide ore, you must first determine which type of ore the copper-sulfur ore is, and then select the appropriate process based on the multi-element analysis report and the grain size of the sulfide.

If you are interested in copper-lead-zinc ore beneficiation, please continue to browse the next article about Cu-Pb Froth Flotation Guidance.

If you have any questions about the extraction of copper from sulfide ore, please leave a message to communicate with us, or consult our online customer service.

- Random article

- Popular articles

- Popular comments

- Gold selection process using resin slurry method

- Nickel ore priority flotation process(Sulfide ore)

- Lithium ore heavy medium beneficiation process

- Zirconium Ore Processing: Gravity, Magnetic, and Electric Separation

- Chromium Ore Gravity Separation and Flotation Process

- Antimony Ore Hand Picking Process for Color Sorting

- Manganese ore washing to achieve the best results

Leave a message with your needs or comments

Add comment: