Centrifugal separator is a kind of equipment that processes minerals by centrifugal force, which is environmental with high beneficiation efficiency. In practice, it is often used for the gravity separation of fine-grained minerals. In recent years, with the development of centrifugal beneficiation technology, especially in the context of environmental protection and sustainable development, centrifugal beneficiation technology and equipment have been favored by major concentrators.

We mainly cover 5 aspects to help you get more knowledge of centrifugal separator:

The structure of centrifugal separator

The working principle of centrifugal separator

The types of centrifugal separator

Key points of centrifugal separator operation

Notes of centrifugal separator

Let’s drive in!

01 Centrifugal Separator Structure

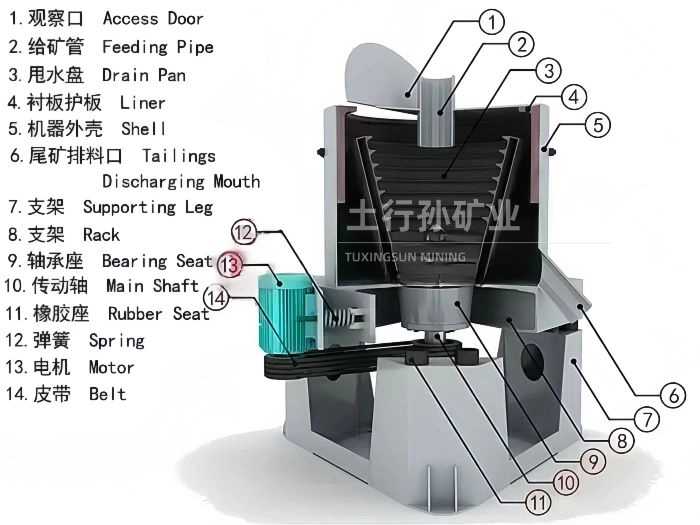

In general, the centrifugal separator mainly consists of two parts, a separating mechanism and an auxiliary mechanism. The separating mechanism is mainly formed by a rotating drum, which is in the shape of a hollow truncated cone, with a slope of 3° to 5° on the inner surface. This rotating drum is usually made of cast steel or cast iron. Compared with separating mechanism, the auxiliary mechanism is composed of relatively more parts, such as ore feeding device, ore discharge device, and washing device.

02 Centrifugal Separator Working Principle

Centrifugal separator is a kind of equipment that separates minerals by centrifugal force. When it working, the rotating drum rotates at a certain high speed, the slurry will be sent to the inner wall of the rotating drum from the slurry distributor to the ore nozzle. Under the centrifugal force, the tailings are discharged by the discharging distributor. After the discharge is completed, the distributor will automatically turn away from the original position to intercept the concentrate until the concentrate is discharged, and then enter the next working.

03 Centrifugal Separator Types

Centrifugal concentrators can be divided into two types, namely horizontal centrifugal concentrator and vertical centrifugal concentrator. The horizontal centrifugal concentrator is mainly composed of a main part and a control part. The main part is a horizontally installed drum. The control part mainly contains 4 parts: feeding, discharging, flushing water and electric motor. In the actual production process, it is mainly used to separate non-ferrous metals such as tungsten ore and tin ore.

For vertical centrifugal concentrators, the installation of the drum is vertical, and most of them are intermittent centrifugal concentrators. Vertical centrifugal concentrators are mostly used to separate gold, silver and other metals, or to process denser minerals.

In addition, there are many types of centrifugal concentrators, but their structures are basically the same.

04 Centrifugal Separator Operation

In order to ensure the normal operation of the centrifugal separator, the operator should grasp some key points, especially for the inspection work before the equipment operation and the equipment load operation.

Inspection Before Operation

Turn on the hydraulic oil pump, check its pressure, and control the pressure value within the specified range;

Check the voltmeter reading of the distribution box to make it stable within the specified range;

Set the transfer switch on the operation panel to the manual position;

Check the fastening of fasteners at various parts to ensure that the large cover is locked;

Check the rotation end position of the scraper to make it in the reset position

Load Operation

When the equipment just starts to run, first make it run to the feeding speed, and then feed the equipment;

The number of washing times and the amount of solvent should be under the operating procedures;

The change of current should be noticed when the separator unloading by the scraper centrifuge.

In practice, expert to master the operating points listed above, the operator also needs to pay attention to the following:

Before operating the centrifugal concentrator, You should be familiar with the structure, principle and operating points of the centrifugal concentrator;

You should control the weight and speed of the material in the drum, the maximum could not exceed the rated value of the centrifugal separator;

If the centrifugal separator has excessive vibration or abnormal noise, you need to immediately turn off the equipment, stop working, cut off the power supply, and find the cause;

Before opening the hole cover of the centrifugal concentrator, you should confirm that the drum must be completely stopped;

You should check the stability of the residual filter cake in the drum in daily life. When the residual filter cake falls, you need to open the door to clean it manually. If it is not cleaned in time, the equipment will have a great vibration at next operation.

05To Wrap Up

When operating centrifugal concentrators, you need to understand the specific model, structure, working principle, operation points and precautions of the centrifugal concentrator. In practice, it may occur many other problems. So you need an equipment manufacturer with overall beneficiation qualifications. When encountering problems, you need to analyze specific problems in detail to ensure the normal operation of the centrifugal concentrator which can avoid unnecessary economic loss.

If you have any questions or want to learn more about centrifugal concentrators, welcome to consult online service or leave a message.

- Random article

- Popular articles

- Popular comments

- Iron Ore Roasting and Magnetic Separation Process

- Gold Mine Heap Leaching: Optimal Process

- Zirconium Ore Separation: Gravity and Magnetic Methods

- Chromium Ore Gravity Separation and Flotation Process

- Chromite Processing: Gravity, Magnetic, and Flotation Separation

- Efficient purification of manganese ore by magnetic separation process

- Tantalum-Niobium Ore Combined Beneficiation Guide

Leave a message with your needs or comments

Add comment: