With a remarkable feature of high rich ore ratio, shaking table is commonly used to obtain the final concentrate, and at the same time separate the final tailings, which can effectively process the granular materials. The upper limit of the separation particle size of the shaking table is 3mm and the lower limit is below 1mm. If the shaking table is used to separate cassiterite and the black tungsten ore, the smallest separation particle size can be 0.4mm.

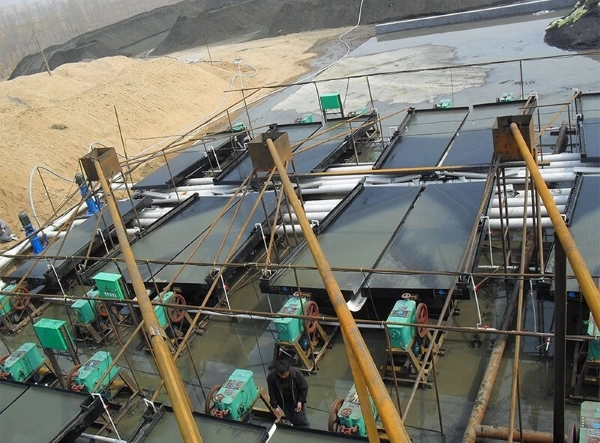

(Shaking table in gold gravity separation plant)

01 How Does A Shaking Table Work?

Shaking table separation is achieved by the combination of the shape of the shaking table surface and the lateral flow of water. The groove on the shaking table surface is longitudinal, perpendicular to the direction of water flow, and a vortex is formed in the groove when the water flows laterally. The interaction of the vortex and the shaking table surface shaking makes the ore layer lose and layered according to density. The heavy minerals move to the lower layer. While the light minerals move to the upper layer. This process is called “separation and layering”. The upper layer of light ore particles is subjected to a larger momentum of water flow, while the lower layer of heavy ore particles is subject to less momentum. So the lateral movement speed of the light ore particles on the shaking table surface is greater than that of the heavy ore particles.

In the longitudinal direction, the differential movement of the shaking table surface promotes loose and layering of the ore, and also makes heavy ore particles move forward in the longitudinal direction at a large speed, and makes the light ore particles move forward at a small speed. Finally, achieve the separation of heavy and light minerals.

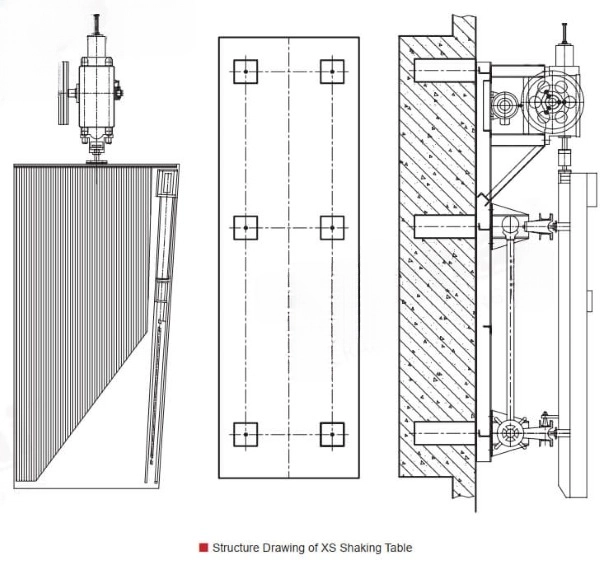

02 What is the Basic Structure of the Shaking Table?

The shaking table is a widely used mineral gravity separation equipment. The shaking table's basic structure is divided into three main parts: the bed surface, the bed head and the frame.

(1) Bed Surface of Shaking Table

The bed surface of the shaking table can be made of wood, fiberglass, metal (such as aluminum, cast iron) and other materials. Common shapes of shaking table include rectangles, trapezoids, and diamonds. A plurality of parallel bed strips (also called strips) are engraved on the surface of the bed in the longitudinal direction or engraved with grooves, and the bed strips are lowered from the transmission end to the opposite side and are pinched off on a diagonal line. The bed surface of the shaking table is supported or lifted by the frame. The bed surface of the shaking table is inclined, inclined from the feeding end to the opposite side in the lateral direction of 1.5°~5°, so that the water flow fed from the ore feeding tank and the flushing tank forms a thin layer of inclined water flow on the bed surface.

There is a feeding tank on the upper right side of the bed surface of the shaking table, the length is about 1/4~1/3 of the total length of the bed surface. There are many small holes in the side of the feeding tank, so that the slurry is evenly distributed on the bed surface of the shaking table. Connected to the mineral tank is a flushing tank, which accounts for 2/3~3/4 of the total length of the bed surface. There are also many small holes in the water tank side, so that the flushing water can be evenly fed along the longitudinal direction of the bed surface. A plurality of flaps are also mounted in the tank to regulate the distribution of water along the length of the bed of the shaking table.

(2) Bed Head of Shaking Table (Transmission Mechanism)

The bed head of the shaking table is driven by the motor, and the bed surface is connected by a tie rod to make the bed surface reciprocate asymmetrically in the longitudinal direction. When the shaking table bed head is moving forward, the speed is slow to fast and then stops quickly. When shaking table bed going backward, the speed increases rapidly from zero to the maximum, and then slowly decreases to zero. The bed surface of shaking table produces longitudinal differential motion, so that the mineral particles on the bed surface can be transported in a single direction. The operation to the concentrate is forward transport, and vice versa.

(3) Suspension Mechanism of Shaking Table

The support of the shaking table bed surface is seated and suspended. The seat type is that the bed surface is directly coupled with the bracket, and a slope adjusting device is arranged on the bracket to adjust the lateral slope of the bed surface. The hanging type is to hang the bed surface on a shelf with a wire rope, and the bed surface is suspended in the air. Adjust the slope to adjust by adjusting the tightness of the wire rope.

03 What are the Common Types of Shaking Table

According to the mechanical structure, shaking table can be divided into 6S shaking table, Yunxi type shaking table, spring shaking table, suspended multi-deck shaking table and flotation shaking table.

(1) 6S Shaking Table

6S shaking table has a wide stroke adjustment range and a strong loose force, which is suitable for separating materials of 0.5-2mm. Its stroke is easy to adjust and keeps running smoothly when the slope is adjusted.

(2) Yunxi Type Shaking Table

The asymmetry of Yunxi type shaking table bedside is large, and has a wide range of differential adjustments to meet different feeding particle sizes and separation requirements. The bed head mechanism runs reliably, and there are a few parts that are easy to wear and do not leak oil. The disadvantage is that the spring is installed below the bed surface, which is inconvenient for maintenance and adjustment of stroke, and the adjustable range of lateral slope is small (0°-5°).

(3) Spring Shaking Table

The bed surface support method and the slope adjustment method of the spring shaking table are the same as those of the Yunxi type shaking table. The bed strip of the bed surface of the spring shaking table is usually formed by the grooving method, and the section of the groove is triangular. The positive and negative movements of the spring shaking table have a large difference in acceleration, which can effectively push the fine particles to move forward along the bed surface, so it is suitable for processing fine-grained materials. The disadvantage is that the stroke will vary with the amount of feed. When the load is too large, the bed will automatically stop moving, and the processing capacity per hour is very low, usually below 100kg.

(4) Suspended Multi-deck Shaking Table

Suspended multi-deck shaking table has a small footprint, large production capacity and low energy consumption. The disadvantage of this shaking table is that it is inconvenient to observe the zoning of the materials on the bed surface, and the product access is not clear. The recovery of -30um wolframite or cassiterite can be up to 50%. The biggest advantage of the spring shaking table is that the price is low, and the bed structure is simple and easy to maintain.

(5) Flotation Shaking Table

Flotation shaking table is mainly used for separating sand ore with coarse particle size, containing tin and non-ferrous sulfide minerals, or tungsten and tin concentrate with polymetallic sulfide minerals, or scheelite - wolframite - cassiterite mixed concentrate, etc. The particle size of the ore is usually 0.2-3mm, up to 6mm in some cases.

04 How to Operate Shaking Table?

(1) The user should test the shaking table before installation on whether the parts of the bed meet the requirements of the drawings, the parts are complete, and the appearance is intact.

(2) The side plate should be prevented from compression deformation and collision with the bed surface of the shaking table during hammock is used.

(3) Install the connector and four connecting blocks before hoisting the bed surface to adjust the height and exact position. The bed surface installation center is consistent with the center of the connector in the machine head.

(4) After the installation and connection are correct, the shaking table needs to run empty for 1-2 hours. Check whether the bed surface is running smoothly, whether the connection part is loose and shaking, or whether the slide is well lubricated with no abnormal noise, and whether the lateral slope adjustment is flexible and stable.

(5) After the bed surface is installed, the holes of each connecting screw should be aligned, with moderate tightness, and the gap between the support and the connecting part should not be too large so as not to cause noise and wear.

(6) If there is no problem in empty running or related operation problems are solved, shaking table can start working with mineral load. According to the ore transportation and zoning on the bed surface, a series of operation specifications can be adjusted including the feeding amount, the ore concentration, the stroke length and stroke frequency system, the cross slope and the flushing water volume.

05 How to Maintain Shaking Table?

(1) It is necessary to regularly check that all parts are in good condition. It mainly includes the bed surface, bedside and rack of the shaking table. First, check whether the surface of the shaking table is in contact with the non-shaking parts and the degree of inclination. If the surface of the shaking table is found to be damaged, resin filling wear-resistant agents can be prepared to repair it.

(2) Check the wear of the headboard parts. When it is found that the wear of the parts is very serious, it needs to be replaced in time.

(3) Check whether the screw is loose, whether the spring is damaged, and whether the sliding surface of the shaking table is in good condition. If there is any abnormal sound, find and eliminate it in time.

(4) When the storage box is shaken, special attention should be paid to prevent the deformation of the shaking table bed surface, and it should not be exposed to sunlight or rain, which may cause moisture.

(5) During shutdown, in order to avoid the oxidation and scaling of impurities, it is necessary to rinse the surface of the shaking table with water. If scaling occurs, it needs to be removed in time.

- Random article

- Popular articles

- Popular comments

- Iron ore reverse flotation process

- Branch serial flow flotation process for lead-zinc ore

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Lithium ore combined beneficiation process

- Zirconium Ore Separation: Gravity and Magnetic Methods

- chrome ore processing:Advanced Magnetic Separation Processing Technology

- Titanium Ore Processing: Magnetic Separation and Flotation

Leave a message with your needs or comments

Add comment: