Ionic rare earth ore chemical beneficiation process is a method used to treat weathered and leached rare earth ores, in which rare earth element ions are mainly adsorbed on clay minerals in the form of hydrated ions. In order to obtain rare earth products, chemical methods can be used to replace or clean the adsorbed rare earth element ions.

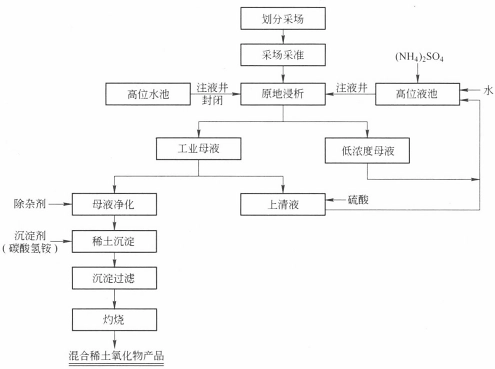

Chemical beneficiation process flow of ion type rare earth ore

1.Ore crushing and grinding:

The raw ore is crushed to a certain particle size to increase the surface area of the mineral and facilitate subsequent chemical treatment.

The crushed ore is further ground to finer particle size, which is conducive to the progress of chemical reactions.

2.Chemical leaching:

Mix mineral powder with an appropriate amount of chemical reagents (such as sulfuric acid, hydrochloric acid, etc.) for chemical leaching reaction.

During the chemical reaction process, rare earth element ions are displaced or washed out from clay minerals, forming soluble rare earth salts.

3.Precipitation and crystallization:

Dilute or concentrate the leachate to control the appropriate concentration and temperature.

In the diluted or concentrated solution, rare earth ions are precipitated and crystallized to form rare earth compounds by adding precipitants (such as sodium hydroxide, ammonium hydroxide, etc.).

4.Solid liquid separation:

The precipitated rare earth compounds undergo solid-liquid separation, such as filtration and washing, to remove impurities and excess chemical reagents.

5.Drying and sintering:

Dry the rare earth compounds after solid-liquid separation to remove moisture and obtain rare earth oxide products.

The dried rare earth oxide can also be sintered to improve the purity and stability of the product.

Technological advantages

Large processing capacity:Chemical beneficiation technology can process a large amount of ore, suitable for large-scale rare earth production.

Directly obtainable rare earth oxide products: Through chemical beneficiation technology, rare earth oxide products can be directly obtained without the need for subsequent physical beneficiation processes.

The ion type rare earth ore chemical beneficiation process uses chemical methods to replace or clean the rare earth element ions adsorbed on clay minerals, which has the advantages of large processing capacity and direct acquisition of rare earth oxide products. This process plays an important role in the rare earth industry and provides effective technical support for the production and application of rare earths.

Typical processes

Jiangxi Ganzhou ion adsorption rare earth ore

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Optimal Flotation Process for Copper Ore (Partial Priority+Mixed)

- Tin ore flotation+gravity separation+magnetic separation process

- Iron Ore Weak Magnetic Beneficiation Process

- Gold selection process using resin slurry method

- Scheelite Flotation Method

- Chromite Gravity and Magnetic Separation Process

- Antimony Ore Hand Picking Process for Color Sorting

Leave a message with your needs or comments

Add comment: