Mixed rare earth ore is a byproduct of iron ore mining, mainly composed of fluorocarbon cerium ore and monazite.

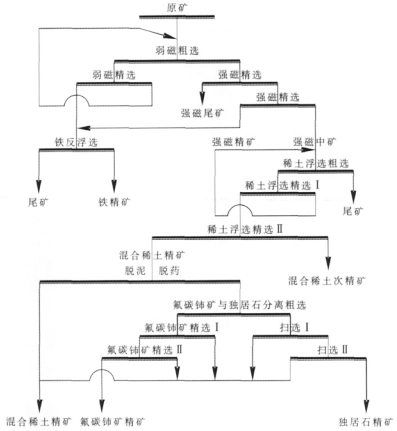

The mixed rare earth ore magnetic separation+flotation process is an effective method for treating ores with more magnetic minerals. This process first removes magnetic minerals through magnetic separation, and then separates rare earth minerals using flotation methods.

Mixed rare earth ore magnetic separation+flotation process flow

1.Magnetic Separation :

Ore crushing:Crushing the original ore to a certain particle size to increase the surface area and conductivity of the mineral, preparing for magnetic separation.

Ore grinding:Grinding the crushed ore into finer particle sizes to achieve better magnetic separation results.

Magnetic separator separation:The ground slurry is fed into the magnetic separator, and the strong magnetic field generated by the separator is used to attract and separate magnetic minerals (such as magnetite). The tailings after magnetic separation contain non-magnetic minerals, including rare earth minerals and other gangue minerals.

2.Concentration:

Tailings concentration:The tailings after magnetic separation contain a large amount of non-magnetic minerals, but may also contain a certain amount of rare earth minerals. These tailings are sent to concentration equipment, such as thickeners or thickeners, to remove impurities and excess water through hydraulic flushing and other methods, thereby increasing the concentration of rare earth minerals.

3.Flotation:

Flotation preparation:The concentrated tailings are used as selected rare earth raw materials for subsequent flotation processes. Before flotation, it is usually necessary to add specific flotation agents, such as collectors and foaming agents, to adjust the properties of the slurry and promote the flotation of rare earth minerals.

Flotation machine separation:send the prepared pulp into the flotation machine, and float the rare earth minerals to the pulp surface to form a foam layer through the bubbles generated by the flotation machine. The rare earth minerals in the foam layer are then collected and dried to finally obtain rare earth concentrate.

Technological advantages

Reduce the complexity of selected materials:By removing magnetic minerals through magnetic separation, the complexity of selected materials is reduced, which is beneficial for subsequent flotation processes.

Improving flotation efficiency:Magnetic separation process can remove some impurity minerals, thereby reducing the consumption of flotation reagents, improving flotation efficiency and rare earth recovery rate.

Improving Resource Utilization:Through the combined process of magnetic separation and flotation, rare earth resources can be more effectively utilized, improving resource utilization efficiency.

The mixed rare earth ore magnetic separation+flotation process is suitable for processing ores with more magnetic minerals, which can reduce the complexity of the selected materials, improve flotation efficiency, and thus improve the utilization and recovery rate of rare earth resources.

Typical beneficiation plant

Baotou mixed rare earth ore: The Baotou mixed rare earth ore has a complex type of ore, including more than 15 types of rare earth minerals, mainly monazite and fluorocarbon cerium light rare earth mixed minerals. The ore is extracted with iron ore, and the main useful minerals are magnetite, hematite, rare earth minerals, etc. Vein minerals are mainly pyroxene, calcite, barite, etc.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Iron Ore Roasting and Magnetic Separation Process

- Carbon leaching beneficiation process for gold mines

- Scheelite Flotation Method

- Gravity combined beneficiation process for wolframite ore

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Radioactive beneficiation and flotation process for uranium ore

Leave a message with your needs or comments

Add comment: