The mixed rare earth ore flotation+selective agglomeration flotation process is a beneficiation method aimed at improving the grade and recovery rate of rare earth concentrate. This process enriches useful minerals into a product through flotation, and then uses the principle of selective agglomeration to further improve the concentrate grade or obtain other products by reprocessing tailings or the aforementioned products.

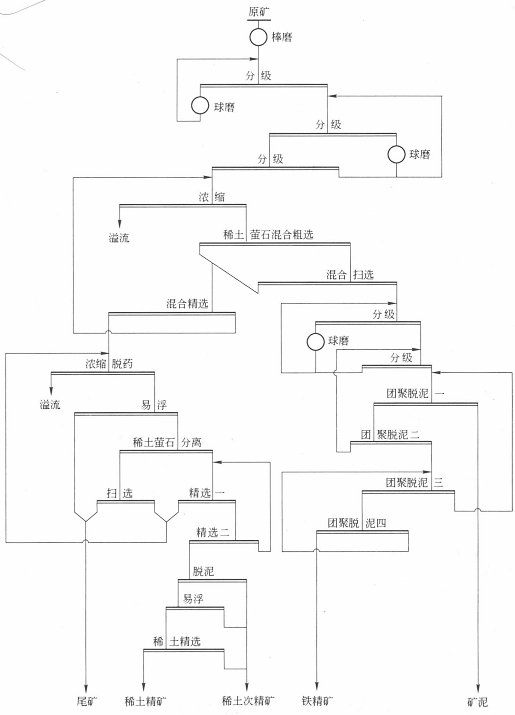

Process flow of mixed rare earth ore flotation+selective agglomeration flotation

1.Flotation:

Ore crushing: Crushing the original ore to a certain particle size to increase the surface area and conductivity of the mineral, preparing for flotation.

Ore grinding: Grinding the crushed ore into finer particle sizes to achieve better flotation results.

Preparation of flotation reagents: Based on the properties of the ore, prepare suitable flotation reagents such as collectors, foaming agents, and adjusters.

Flotation machine separation:The ground slurry is fed into the flotation machine. Under the action of flotation reagents, rare earth minerals are separated from gangue minerals and enriched into flotation foam.

Foam collection:the rare earth minerals in the flotation foam are collected to form flotation concentrate.

2.Selective Agglomeration Flotation:

Tailings or concentrate preparation:Using flotation tailings or concentrates as raw materials for selective agglomeration flotation.

Preparation of Aggregating Agent:Choose a suitable aggregating agent, which can agglomerate rare earth minerals into larger particles.

Aggregation flotation machine separation:Send the prepared slurry into the agglomeration flotation machine. Under the action of agglomeration agents, rare earth mineral particles aggregate into larger agglomerates.

Aggregated particle collection:The agglomerated particles are collected to form high-grade concentrate.

Process advantages

High concentrate grade:Through the reprocessing of selective agglomeration flotation, the grade of the concentrate can be further improved.

Simple process:Compared with other complex beneficiation processes, the flotation+selective agglomeration flotation process is relatively simple and easy to operate.

The combined rare earth ore flotation and selective agglomeration flotation process can enrich useful minerals into a product through flotation, and reprocess tailings or the aforementioned products through the principle of selective agglomeration flotation, thereby improving the concentrate grade or obtaining other products. This process has the advantages of high concentrate grade and simple process.

Typical beneficiation plant

Baiyun Ebo rare earth coexisting ore: A selective agglomeration separation method has been developed for the separation of fine-grained hematite and iron containing silicate minerals in Baiyun Ebo iron ore; By selectively agglomerating and desliming, further desliming is carried out after adding chemicals to the settling sand to improve the concentrate grade.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Iron ore reverse flotation process

- Lead zinc ore mixing+separation flotation process

- Nickel ore priority flotation process(Sulfide ore)

- Lithium ore heavy medium beneficiation process

- Lithium ore combined beneficiation process

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

- Lithium Ore Processing: Gravity Separation and Flotation

Leave a message with your needs or comments

Add comment: