There are a total of 17 rare earth elements, divided into light rare earth (cerium group) and heavy rare earth (yttrium group). The absolute amount of rare earth elements is large, but there are not many that can become exploitable rare earth minerals. Rare earth minerals often exist in the form of complex oxides, silicates, phosphates, fluorocarbonates, and fluorides. The most important rare earth industrial minerals include fluorocarbon cerium ore, monazite, yttrium phosphate ore, and brown yttrium niobium ore.

The gravity flotation process of rare earth ore is a commonly used rare earth ore beneficiation method, which is mainly characterized by improving flotation efficiency through gravity separation and early tailings disposal.

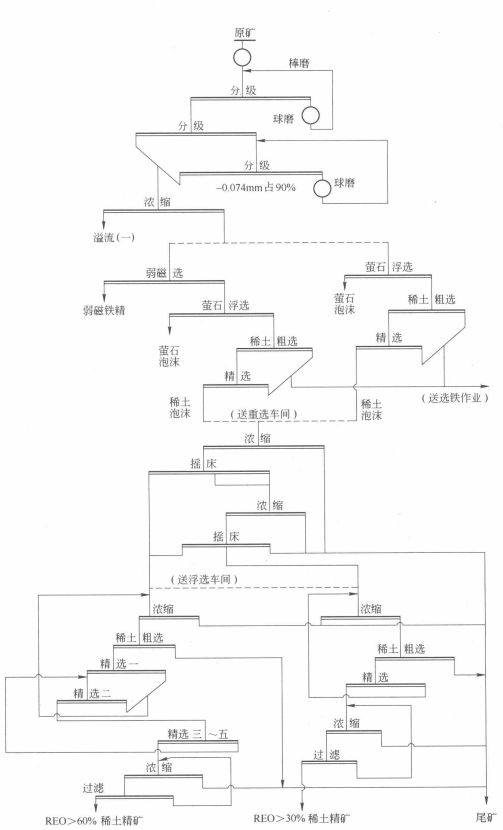

Rare earth ore re selection+flotation process flow

1.Ore preparation:Crush and grind the collected rare earth ore to achieve appropriate particle size for re selection and flotation.

2.Gravity separation:Use appropriate gravity separation equipment and reagents to separate minerals with large density differences in rare earth ores. Common gravity separation equipment includes hydrocyclones, spiral concentrators, jigs, etc. Re selection can separate minerals with large density differences from fine mud, thereby improving flotation efficiency and early tailings disposal.

3.Flotation:The re selected rare earth ore is subjected to flotation to further separate useful rare earth minerals. Common flotation reagents include cationic collectors, anionic collectors, and activators. Flotation can separate useful rare earth minerals from gangue minerals and impurities, thereby improving flotation efficiency.

4.Concentrate treatment: Further treatment is carried out on the rare earth concentrate after flotation to improve its purity and grade. The processing methods include magnetic separation, re selection, chemical leaching, etc.

5.Concentrate production:The processed rare earth concentrate can be produced as the final product, or further separated and purified to obtain higher purity rare earth metals.

Technological advantages

By improving flotation efficiency through gravity selection and early tailings disposal, effective separation and recovery of rare earth minerals can be achieved. Meanwhile, due to the absence of complex chemical treatments, the re selection flotation process has a relatively small impact on the environment. Therefore, the rare earth ore gravity flotation process is widely used in the beneficiation production of rare earth ores.

Typical beneficiation plant

Baotou Iron and Steel Concentrator: Baotou Iron and Steel Concentrator, which deals with Baiyunebo ore, floats some fluorite first, and then carries out rare earth flotation. The obtained rare earth foam products enter the gravity concentration workshop, and the shaking table gravity concentration concentrate enters the flotation workshop again for further cleaning, and finally obtains high-grade rare earth concentrate products.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Stepwise priority flotation process for copper ore

- Tin ore gravity processing technology

- Arsenic Gold Ore Oxidation Roasting Pretreatment Process

- Nickel Ore Mixing and Separation Flotation Process

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Lithium ore magnetic separation process

- Lithium Ore Processing: Gravity Separation and Flotation

Leave a message with your needs or comments

Add comment: