The gravity magnetic separation process for rare earth ore is a physical beneficiation method that combines gravity and magnetic separation processes to treat ores with significant density and magnetic differences. The advantages of this process lie in its environmental friendliness, cost-effectiveness, and ease of operation.

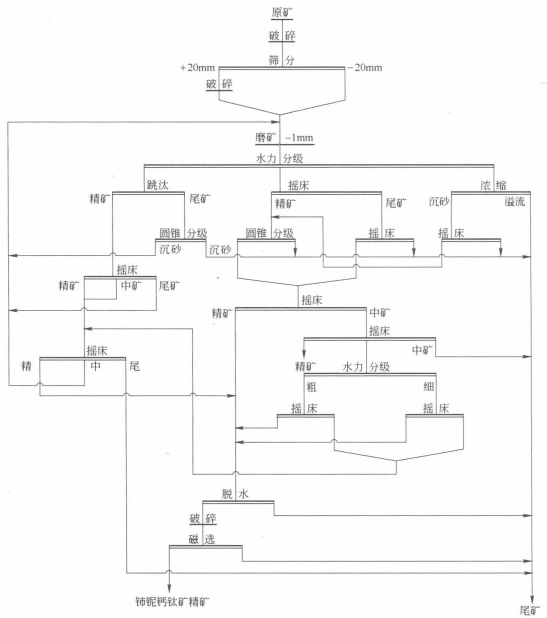

Rare earth ore gravity and magnetic separation process flow

1.Reselection process:

By utilizing the characteristics of different mineral densities in ores, minerals can be separated through hydraulic or mechanical methods. Common equipment includes hydrocyclones, heavy medium beneficiation machines, spiral beneficiation machines, etc.

The gravity separation process usually involves suspending ores in water and separating them using the different densities of minerals. Heavier minerals sink to the bottom of the pool, while lighter minerals are carried out by water flow.

2.Magnetic separation process:

Utilize the magnetic differences of minerals in ore for separation. By using magnetic separators such as permanent magnet drum separators or electromagnetic separators, magnetic minerals are separated from non-magnetic minerals.

The magnetic separation process does not require chemical agents, so it has minimal impact on the environment and reduces processing costs.

3.Concentrate processing:The rare earth concentrate obtained by gravity and magnetic separation processes may require further processing, such as flotation, hydrometallurgy, or other chemical methods, to further improve the purity and recovery rate of rare earth elements.

Technological advantages

This process is particularly suitable for rare earth ores that contain a large amount of magnetic minerals and have significant density differences. By reselection, a portion of non-magnetic impurities can be removed first, and then magnetic separation can be used to recover magnetic rare earth minerals, thereby improving the recovery rate and grade of rare earth minerals.

Typical beneficiation plant

Cerium niobium perovskite beneficiation plant in Kola Peninsula, Russia: Cerium niobium perovskite has weak magnetism and is a complex containing rare earth, niobium, and titanium. The vein minerals of this mine are nepheline, aegirine, etc., and the useful minerals are embedded with coarse particle size, making it easy for gravity and magnetic separation processing.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Lithium ore magnetic separation process

- Lithium ore heavy medium beneficiation process

- Lithium Ore Processing: Gravity Separation and Flotation

- chrome ore processing:Advanced Magnetic Separation Processing Technology

- Understanding the Manganese Ore Flotation Process

- Titanium Ore Processing: Magnetic Separation, Gravity Separation, Flotation

- Rutile Processing: Gravity, Magnetic, Flotation, Electric Separation

Leave a message with your needs or comments

Add comment: