The flotation process of fluorocarbon cerium ore is a common rare earth ore beneficiation method, which is characterized by the ability to directly obtain rare earth concentrate products using a single flotation method, and the process is simple and mature.

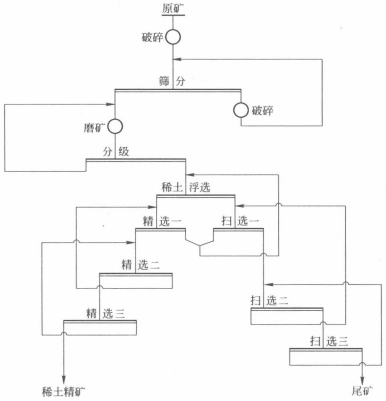

Flotation process flow of fluorocarbon cerium ore

1.Ore crushing:Crush the ore to a certain particle size. Then, the crushed ore is ground to achieve a suitable particle size, usually between a few micrometers to tens of micrometers. This can increase the surface area of minerals and improve flotation efficiency.

2.Mixing slurry:The slurry after grinding needs to be adjusted to the appropriate pH value, concentration, temperature and other conditions. The purpose of slurry mixing is to ensure that the minerals in the slurry can effectively react with flotation reagents, thereby improving flotation efficiency.

3.Addition of flotation reagents:After mixing, add flotation reagents to the slurry. Flotation reagents include collectors, foaming agents, and adjusters. The collector is used to selectively adsorb on the surface of the target mineral, enabling it to float up; Foaming agent is used to produce foam and bring the target mineral to the pulp surface; Adjusting agents are used to adjust the pH value, ion strength, etc. of the slurry to optimize flotation efficiency.

4.flotation:Flotation is carried out in a flotation machine. The pulp is mixed with air in the flotation machine to produce foam. Due to the role of collectors, the target minerals will preferentially adsorb on the foam and float to the pulp surface together with the foam.

Technological advantages

1.Efficient enrichment:The flotation process can efficiently separate and enrich rare earth elements from ores, obtaining high-grade products. By selecting appropriate flotation reagents and adjusting flotation conditions, effective capture of target minerals can be achieved, thereby improving the recovery rate of rare earth elements.

2.Relatively simple:The flotation process is relatively simple and easy to operate. Flotation equipment such as flotation machines and stirring tanks have relatively simple structures and are easy to control and maintain. Meanwhile, the flotation process is relatively short, which can reduce the equipment’s footprint and construction costs.

3.Low cost:Compared to other mineral processing methods, flotation processes typically have lower costs. The price of flotation reagents is relatively low, and the operating energy consumption of flotation equipment is low. Therefore, flotation technology has certain economic advantages.

4.Strong adaptability:The flotation process can adapt to changes in the properties of different ores. By adjusting the type and concentration of flotation reagents, pH value, stirring speed and other conditions, it is possible to adapt to the flotation needs of different ores, thereby achieving good flotation results.

5.Environmentally friendly:Flotation technology usually does not produce a large amount of solid waste and harmful substances during the beneficiation process. There are also certain environmental requirements for the selection and recycling of flotation reagents, which can reduce their impact on the environment.

It should be noted that the efficiency and effectiveness of the flotation process are influenced by the properties of the ore, the selection of flotation reagents, and process parameters. Therefore, optimization and adjustment need to be made according to specific circumstances.

Typical beneficiation plant

Weishan Rare Earth Mine Dressing Plant: The main minerals of this ore vein are barite, quartz, calcite, and dolomite. The rare earth minerals are mainly fluorocarbon cerium ore and a small amount of fluorocarbon calcium cerium ore and monazite. The ore has a relatively simple composition and belongs to the category of fragile, easy to grind, and easy to concentrate ore.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Copper Ore Flotation and Magnetic Gravity Combined Process

- Hg-ore Gravity selection+flotation process

- Gold selection process using resin slurry method

- Cyanide Gold Preparation

- Branch serial flow flotation process for lead-zinc ore

- Nickel Ore Mixing and Separation Flotation Process

- Laterite Nickel Ore: Pyrometallurgical Treatment

Leave a message with your needs or comments

Add comment: