The gravity beneficiation process of rare earth fluorocarbon cerium ore is a method of ore separation based on mineral density differences.

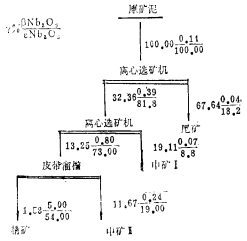

Process flow of fluorocarbon cerium ore gravity separation

1.Ore crushing:Crush the original ore to a certain particle size. The particle size of the crushed ore is usually below 50mm, which can increase the surface area of the mineral and provide better conditions for subsequent gravity beneficiation.

2.Grinding:Grind the crushed ore to a finer particle size. The particle size of the ore after grinding is usually between a few micrometers to several tens of micrometers. This can further increase the surface area of minerals and improve the efficiency of gravity beneficiation.

3.Gravity beneficiation:Gravity beneficiation is a method of separation that utilizes the density difference of minerals. In the process of gravity beneficiation, equipment such as chutes, jigs, or heavy medium beneficiation machines are used. By adjusting the medium density, the denser fluorocarbon cerium ore settles, while the denser gangue minerals float to the surface of the slurry.

4.Product separation:After gravity beneficiation, two products can be obtained: underflow and overflow. The bottom flow mainly contains high-density fluorocarbon cerium minerals, while the overflow mainly contains low-density gangue minerals. These two products can be further processed as needed.

5.Tailings treatment:The tailings generated during gravity beneficiation are mainly gangue minerals and small rare earth minerals. Tailings can be further processed, such as flotation or chemical beneficiation, to recover rare earth elements from them.

Technological advantages

1.Simple process:Gravity beneficiation technology is relatively simple, mainly including steps such as crushing, grinding, and gravity beneficiation. These steps are easy to understand and implement, without the need for complex equipment and process flow.

2.Mature process:Gravity beneficiation, as a traditional beneficiation method, has a long history and rich practical experience. After long-term improvement and development, this process has become very mature and can effectively achieve the separation and enrichment of ores.

3.Cost saving:Gravity beneficiation processes typically have lower costs. The equipment operates with low energy consumption and does not require a large amount of auxiliary equipment and materials. In addition, the maintenance and operation of gravity beneficiation technology is relatively simple, which can save labor and material costs.

4.Environmentally friendly:Gravity beneficiation processes usually do not produce large amounts of solid waste and harmful substances. The media used in the beneficiation process can also be recycled and reused to reduce its impact on the environment.

5.Strong adaptability:Gravity beneficiation technology can adapt to changes in different ore properties. By adjusting parameters such as medium density and particle size, it is possible to adapt to the flotation needs of different ores and achieve good beneficiation results.

The gravity beneficiation process is simple and mature, with the advantages of cost saving and environmental friendliness. Meanwhile, it can adapt to changes in the properties of different ores and has strong adaptability. However, the efficiency and effectiveness of gravity beneficiation are influenced by the properties of the ore, medium density, and process parameters, so it is necessary to optimize and adjust according to specific circumstances.

Typical beneficiation plant

Maoniuping Rare Earth Mine in Mianning, Liangshan, Sichuan: This mining area is mainly composed of light rare earth elements, accompanied by molybdenum ore, fluorite, and barite.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Copper Ore Flotation and Wet Beneficiation Process

- Tin ore magnetic separation+electric separation process

- Gravity beneficiation process for iron ore

- Gold Mine Combined Beneficiation Process

- Branch serial flow flotation process for lead-zinc ore

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

Leave a message with your needs or comments

Add comment: