By utilizing differences in mineral density and magnetism, some gangue minerals or target minerals are selected, and then flotation is used to separately reprocess a portion or all of the products from the aforementioned operations

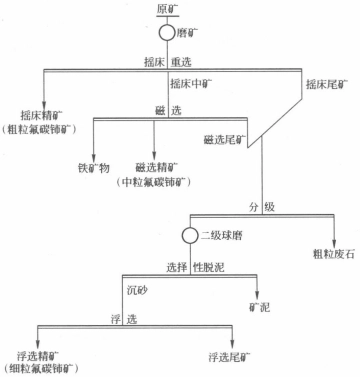

Rare earth ore gravity separation+magnetic separation+flotation process flow

1.Gravity beneficiation:

In the re selection stage, the separation of fluorocarbon cerium ore from other minerals is based on density differences. This process usually uses equipment such as chutes, jigs, or heavy medium beneficiation machines.

The ore is first crushed and ground to achieve the appropriate particle size. Then, by adjusting the medium density, the denser fluorocarbon cerium ore settles, while the denser gangue minerals float to the surface of the slurry.

The main purpose of re selection is to pre separate some gangue minerals and provide relatively pure raw materials for subsequent magnetic separation and flotation.

2.magnetic separation:

Magnetic separation utilizes the magnetic differences between fluorocarbon cerium ore and gangue minerals for separation. This process usually uses wet or dry magnetic separators.

In the magnetic separation stage, by applying a magnetic field, magnetic fluorocarbon cerium minerals are attracted to the magnetic poles, thereby separating from non-magnetic gangue minerals.

Magnetic separation can further enrich fluorocarbon cerium ore and reduce the processing capacity of subsequent flotation.

3.flotation:

Flotation utilizes the differences in surface properties between fluorocarbon cerium ore and gangue minerals to achieve separation. This process requires the addition of flotation agents, such as collectors and foaming agents.

The conditions such as pH value, temperature, mixing speed and reagent concentration of slurry need to be strictly controlled to ensure that bastnaesite can effectively float up to form foam products, while gangue minerals remain in the bottom flow.

Flotation can further improve the grade of fluorocarbon cerium ore and ultimately obtain relatively pure rare earth element products.

Technological advantages

The advantage of the entire gravity magnetic separation flotation process is that it improves the recovery rate of rare earth elements and the grade of the ore through multi-stage selective separation. Meanwhile, this process has high flexibility and can be adjusted according to the properties of the ore and the beneficiation objectives. In practical operation, other beneficiation methods such as electric or chemical beneficiation can be added as needed to further improve beneficiation efficiency.

Typical beneficiation plant

Yaniuping Rare Earth Mine: Shaker gravity separation can directly obtain coarse-grained fluorocarbon cerium ore concentrate. After the intermediate ore is dried, it enters magnetic separation to obtain iron minerals and medium sized fluorocarbon cerium ore, respectively. The magnetic separation tailings are mixed with the shaking bed tailings for flotation, ultimately obtaining fine-grained fluorocarbon cerium ore.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Copper ore stage grinding and selection process

- Iron ore positive flotation process

- Understanding the Gold Mine Flotation Process

- Carbon leaching beneficiation process for gold mines

- Prioritized Flotation Process for Lead-zinc Ore

- Laterite Nickel Ore Hydrometallurgical Process for Oxide Ore

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

Leave a message with your needs or comments

Add comment: