The fluorocarbon cerium ore electrical separation process is a mineral processing method that utilizes the differences in conductivity of different minerals in the ore to achieve separation. The electric separation process is usually combined with other beneficiation methods as an auxiliary means in rare earth beneficiation to improve beneficiation efficiency and product quality.

Electric separation is a method of separation that utilizes the differences in conductivity of different minerals in ores. Minerals with good conductivity (such as magnetite) will move towards the cathode when passing through an electric field, while minerals with poor conductivity (such as fluorocarbon cerite) will move towards the anode. In this way, by controlling the intensity and direction of the electric field, mineral separation can be achieved.

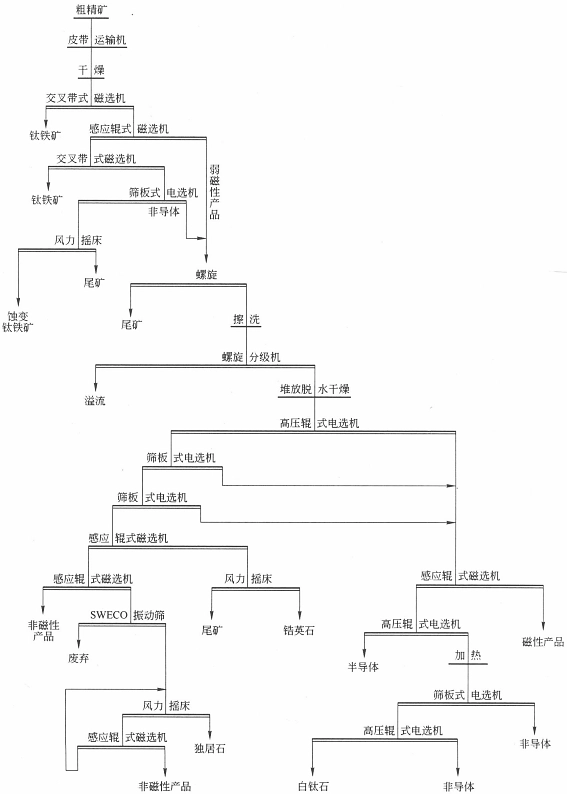

Process flow of fluorocarbon cerium ore electric separation

The electric separation process of fluorocarbon cerium ore is usually combined with other beneficiation methods, such as magnetic separation, flotation, etc. The electrical separation process can serve as an auxiliary means for these methods to further separate minerals with significant differences in conductivity. The specific process flow may vary depending on the properties of the ore and the beneficiation objectives, but generally includes the following steps:

1.Ore crushing:Crushing the original ore to a certain particle size to increase the surface area and conductivity of the mineral.

2.Ore grinding:Grinding the crushed ore into finer particle sizes to improve the effectiveness of electrical separation.

3.Magnetic separation or flotation:Before electrical separation, some impurity minerals are removed through methods such as magnetic separation or flotation to reduce the complexity of the ore.

4.Electric separation:feeding ore into an electric separator. By controlling the intensity and direction of the electric field, minerals with good conductivity move towards the cathode, while minerals with poor conductivity move towards the anode, thus achieving separation.

5.Product drying:The products after electrostatic separation usually require drying treatment to remove moisture and obtain dry rare earth concentrate.

Technological advantages

1.No need for reagents:Unlike flotation and other methods, the electric separation process does not require the use of reagents, thereby reducing environmental pollution and reagent costs.

2.Wide adaptability:The electric separation process can adapt to changes in the properties of different ores, and has better separation effects for minerals with significant differences in conductivity.

3.Product Drying:After electrostatic separation, products usually need to undergo drying treatment to obtain dry rare earth concentrate, improve product quality and stability.

The fluorocarbon cerium ore electric separation process, as an auxiliary beneficiation method, has advantages such as no need for reagents, wide adaptability, and product drying in rare earth beneficiation. By combining with other mineral processing methods, mineral processing efficiency and product quality can be improved.

Typical beneficiation plant

Keppel Selection Plant of Western Australian Mineral Sands Company: The original ore has a heavy mineral content of 5% -12%, with monazite accounting for only 0.5%. Other minerals mainly include ilmenite, perovskite, zircon, and rutile.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore gravity+flotation process

- Laterite Nickel Ore Hydrometallurgical Process for Oxide Ore

- Uranium Ore Radioactive Treatment Process

- Antimony Ore Hand Picking Process for Color Sorting

- Copper-Molybdenum Ore Separation & Flotation Process

- Rutile Gravity Separation, Magnetic Separation, and Flotation Process

- Tantalum-Niobium Ore Processing: Gravity, Magnetic, and Electric Separation

Leave a message with your needs or comments

Add comment: