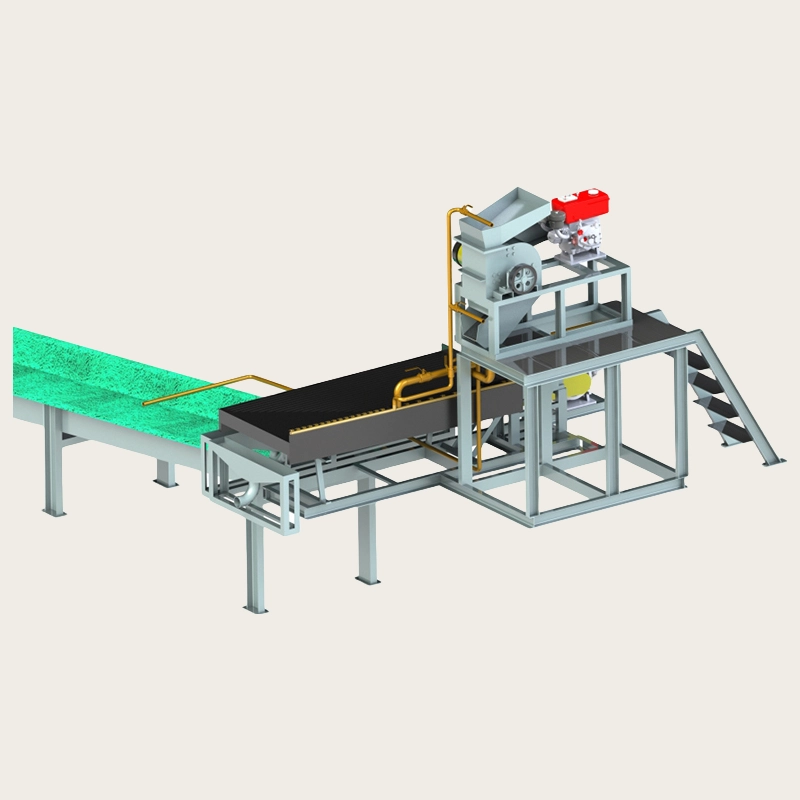

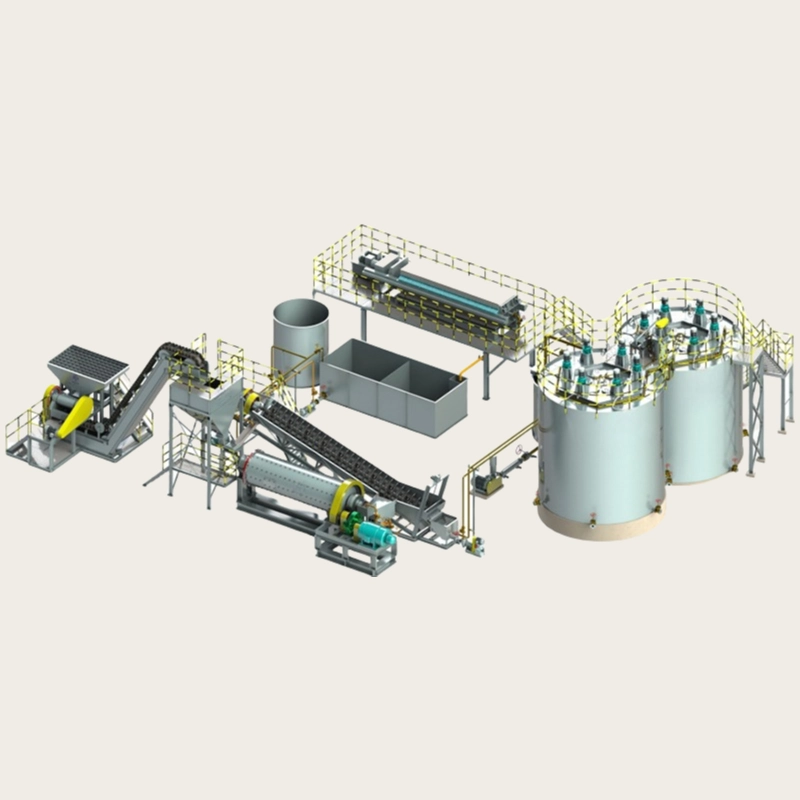

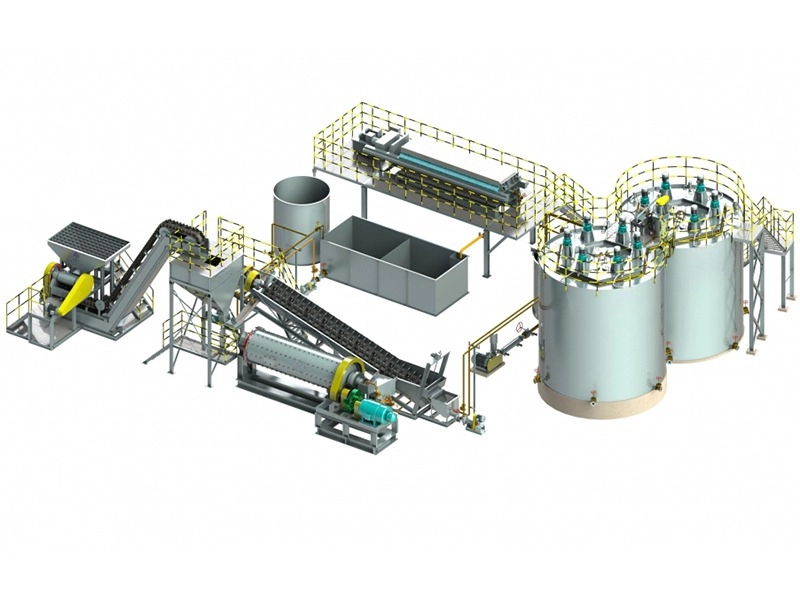

1. Application: The machine is suitable for no road river, mountain & valley area for sedimentary gold washing.

2. Capacity: 15-100t/h

3. Feeding size: <300mm

River Gold Mining Equipment

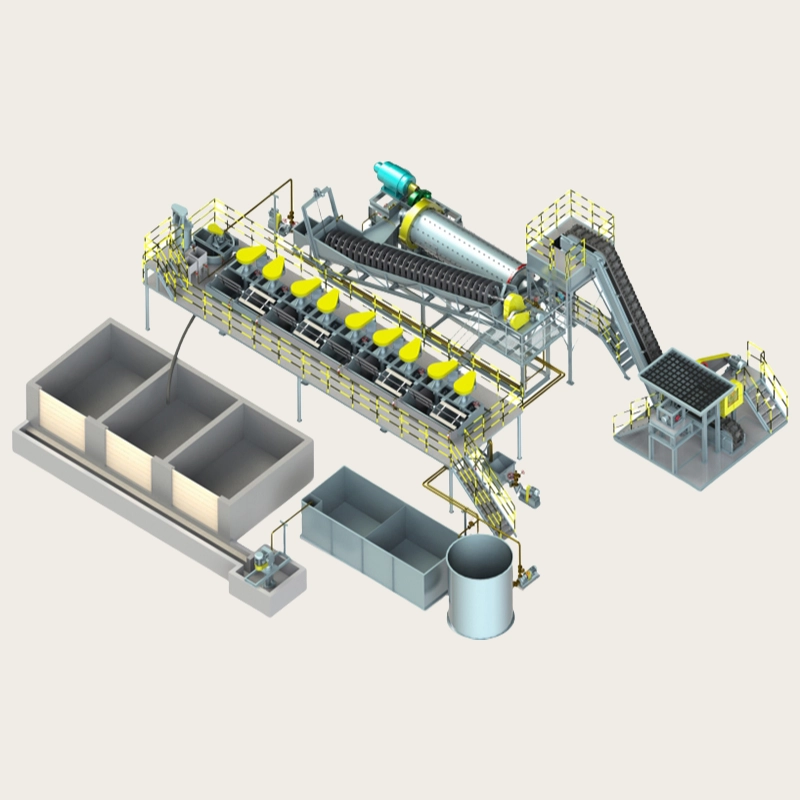

1. Hydraulic motor.

2. Connect this steel pipe and the steel pipe on the column 1 with the plastic steel wire pipe.

3. Column 2.

4. Connect the pump outlet pipe here.

5. Column 1.

6. Rotate in the direction shown by the arrow.

7. Bottom sluice box.

8. Sluice box 1. covered with plastic turf. Both sides are fixed with 3# angle steel and wooden wedge.

9. Sluice box 2. covered with plastic turf. Both sides are fixed with 3# angle steel and wooden wedge.

10. Oil inlet pipe.

11. Oil outlet pipe.

12. Oil recovery pipe.

13. Diesel engine.

14. Hydraulic pump.

15. Oil tank.

16. Radiator.

17. Inlet pipe.

18. Outlet pipe.

19. Upper sieve.

20. lower sieve.

21. Inlet pipe.

22. Three position four way valve. When the handle is in the middle position, start the diesel engine, adjust the speed of the diesel engine around 2000 r/min, and push the handle forward. And observe the rotation direction of the hydraulic motor, whether it is correct or not. If the rotation is opposite, push the handle back.

23. The other end of the tube is connected to the oil outlet of the hydraulic pump.

24. The other end of the tube is connected to the oil inlet of the hydraulic pump.

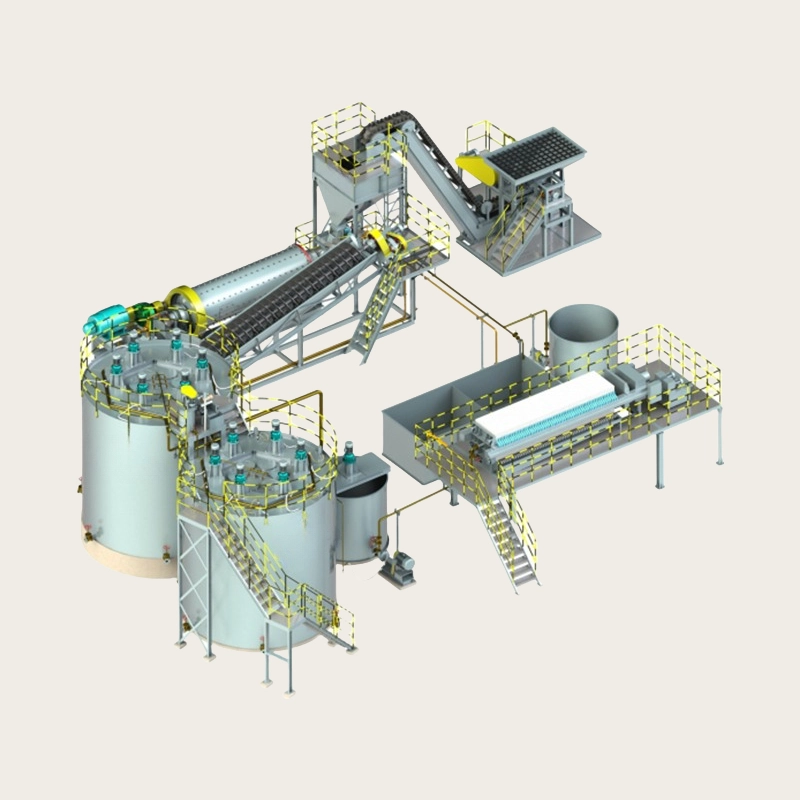

Technique Information

| Model | DME-25 | DME-50 | DME-80 |

| Capacity(T/H | 15-20 | 30-50 | 60-100 |

| Diesel Engine Power | 5.5kw/8.0HP | 7.7-11.0kw/10-15HP | 15-17.0kw/20-24HP |

| Oil Consumption(L/H) | 2 | 3.5 | 5 |

| Power output | Hydraulic pressure | Hydraulic pressure | Hydraulic pressure |

| Vibration Frequency | 480-960 times/min | 480-960 times/min | 480-960 times/min |

| Feeding size | <300mm | <300mm | <300mm |

| Screening size | 3-10mm/20-50mm | 3-10mm/20-50mm | 3mm-10mm/20mm-80mm |

| Water pump | KOOP-80 | KOOP-100 | KOOP-120 |

| Water consumption | 30-50m³/h | 60-100m³/h | 120-180m³/h |

| Sluice box size(mm) | 2150*1000*2pcs | 2850*1350*2pcs | 3250*1500*2pcs |

| Working angle | 6° -12° | 6° -12° | 6° -12° |

| Feed density(%) | 25-40 | 25-40 | 25-40 |

| Dimension(mm) | 3100*1480*2880 | 3600*2020*3300 | 3980*2150*3300 |

| Total weight | 2.0ton | 2.5ton | 3.0ton |

| Movement mode | Tug/tow | Tug/tow | Tug/tow |

Why choose us?

We are a reliable supplier of high-quality Alluvial Gold Washing Plant products with a commitment to excellence.

We only focus on high cost-effective and high-quality products, we will never cut corners, in order to better.

Our Alluvial Gold Washing Plant products are of exceptional quality, and we offer professional services to our customers.

We believe that customers are our sincere friends, and will make customers satisfied with our eternal goal.

We pride ourselves on using only the finest materials to produce our high-quality Alluvial Gold Washing Plant products.

We pay attention to and even exceed the needs of our customers, and provide them with the best quality and efficient Placer Gold Mining Machines.

We use only the highest quality materials and technology to produce our Alluvial Gold Washing Plant products.

Our products cover the entire industrial chain from upstream production to downstream recycling, achieving green, circular and sustainable development.

We have a passion for producing high-quality Alluvial Gold Washing Plant products that meet the needs of our customers.

We believe that forming a team of one heart and one mind is the backbone of the enterprise’s prosperity, and it is the driving force of the enterprise’s core development.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Copper Ore Partial Mixed Flotation Process

- Selective flocculation beneficiation process for bauxite

- Understanding the Gold Mine Flotation Process

- Gold Mine Gravity Beneficiation Process

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Lithium ore reverse flotation process

- Chromite Gravity and Magnetic Separation Process

Leave a message with your needs or comments

Add comment: