Description:

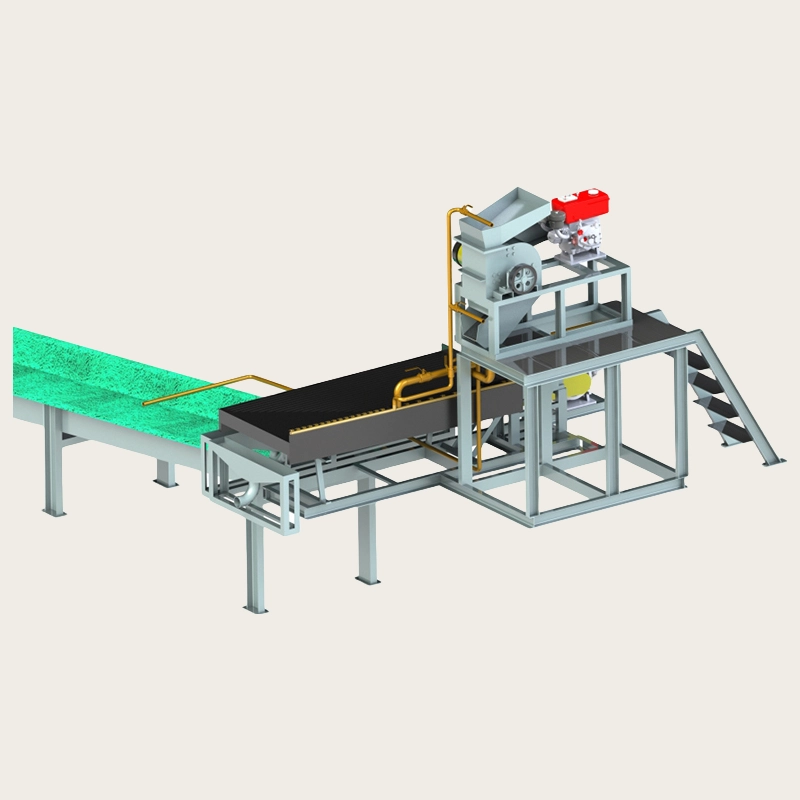

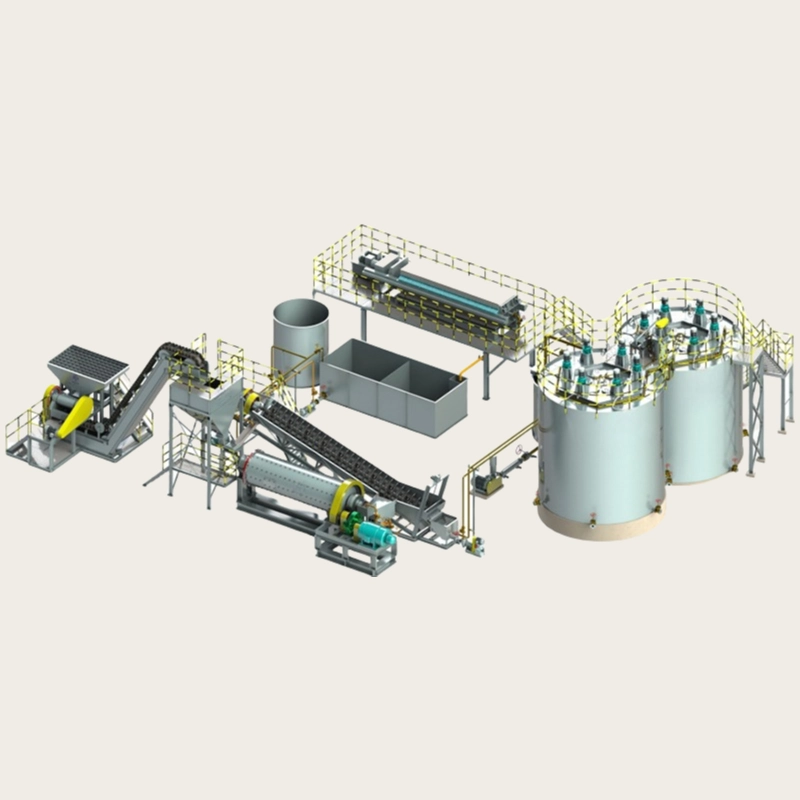

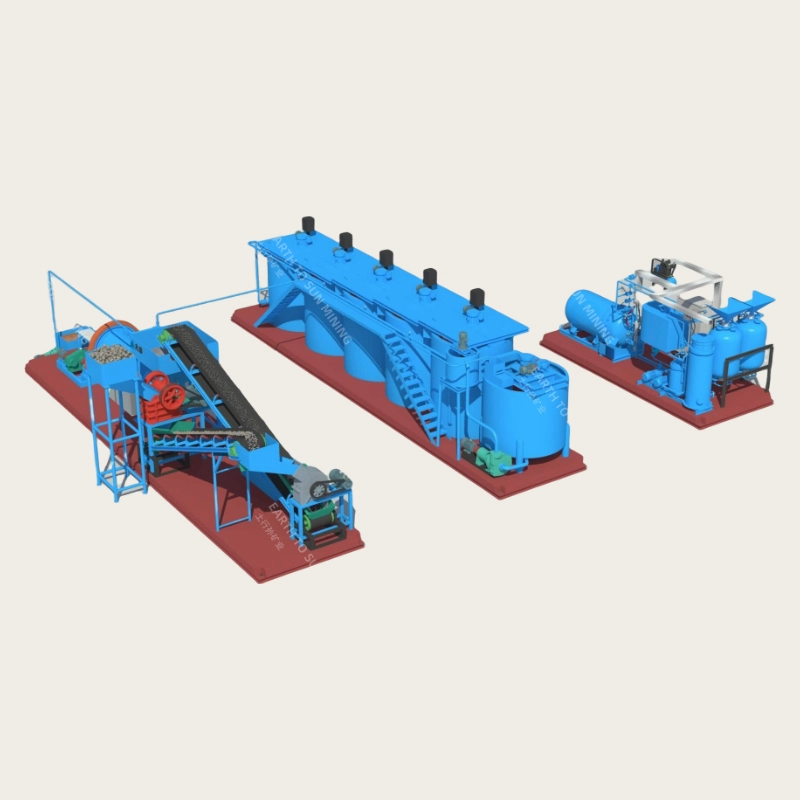

The Mini Gold Wash Plant is a compact and portable machine designed for washing placer gold. It has a capacity range of 10-180tph and includes essential components such as a hopper, vibrating screen, sluice, motor, and water pump. Additionally, there are optional features available, including a trommel screen, gold centrifugal concentrator, shaking table, gold melting furnace, and gold bar production.

Specifications

Structure: Hopper, Vibrating Screen, Sluice, Motor, Water Pump

Optional: Trommel screen, Gold centrifugal concentrator, Sluice box, Shaking table, Gold melting furnace, Gold bar production

Capacity: 10-180tph

Applications: Alluvial gold, sand gold, river gold, rock gold separation, etc.

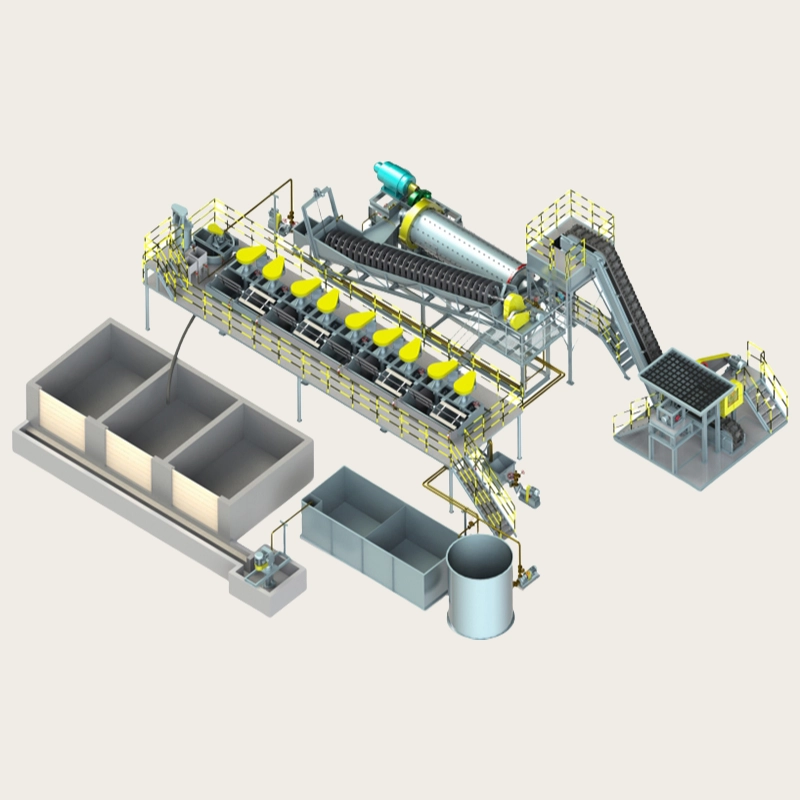

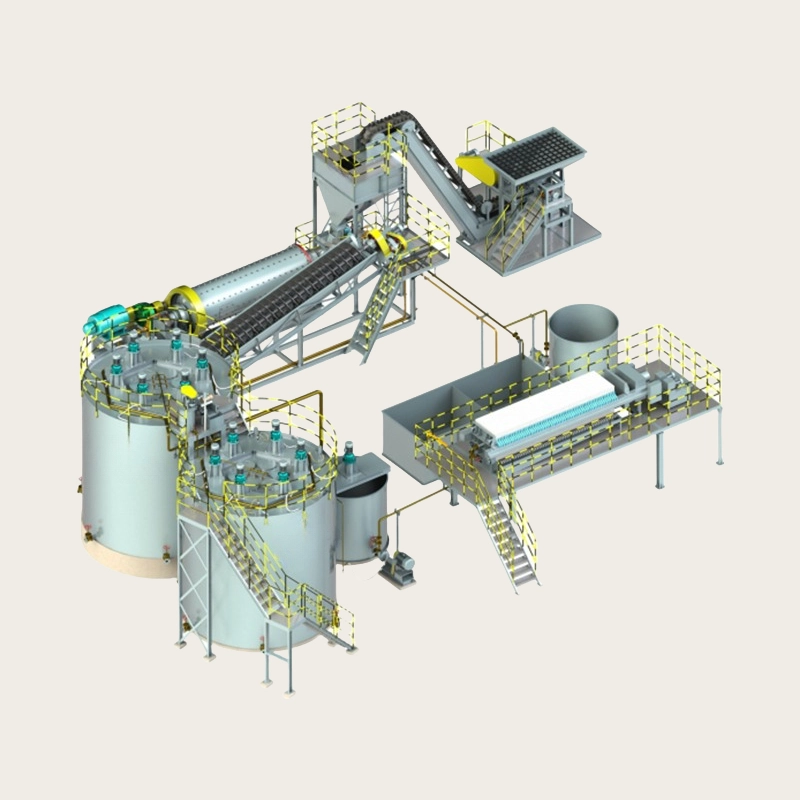

Working Principle: The machine consists of two parts – one for washing clay and the other for sieving different sizes of ores. The drum is supported by four carrier rollers and rotates through a gear mechanism. The washing part separates clay and ore, while the sieving screen separates different-sized ores. The discharge hopper collects larger ores, while smaller ones continue to the next machine, such as a sluice box or centrifugal concentrator.

Features

Efficient washing of clay and screening of ores.

High production capacity and efficiency (10-180tph).

Low operating cost, easy maintenance, and low noise.

Customizable length and diameter of drum unit, screen mesh, and layer quantity.

Can be made in mobile or stationary type.

Advantages

Low price compared to other machines.

High efficiency in catching both big and small gold granules with different types of carpet.

Easy installation and operation with light weight and small size.

Simple maintenance with only the carpet requiring service or replacement.

Large capacity, customizable dimensions to meet specific requirements.

No power consumption, providing convenient operation.

Technique Information:

| Model | MGT50 | MGT100 | MGT150 |

| Performance | |||

| Size(LxWxH)mm | 7000*2000*3000 | 8300*2400*4700 | 9800*3000*5175 |

| capacity | 50-100tph | 100-150tph | 200-300tph |

| Main power | |||

| power | 24kw | 50kw | 75kw |

| Feeder hopper | 2000*2200mm | 3000*2200mm | 3800*3000mm |

| Sluice box&carpet | |||

| Size(WxL) | 1000*6000mm | 1000*6000mm | 1000*6000mm |

| quantity | 2pcs | 2pcs | 3pcs |

| Water system | |||

| Pump power | 7.5kw | 30kw | 45kw |

Common Questions and Solutions

Q: How is the Mini Gold Wash Plant powered?

A: The machine is powered by a motor and doesn’t require additional power sources.

Q: Can the Mini Gold Wash Plant be used for other minerals besides gold?

A: This machine is specifically designed for gold washing, but it may be adaptable for other similar minerals depending on their characteristics.

Q: Is the Mini Gold Wash Plant suitable for large-scale mining operations?

A: The Mini Gold Wash Plant is primarily designed for small-scale mining projects or individual prospecting activities. For larger operations, alternative equipment may be more appropriate.

Q: How long does it take to set up the Mini Gold Wash Plant?

A: The machine is relatively easy to assemble and can be set up manually. The exact time required will depend on the experience and skill of the operator.

Why choose us?

Our Chinese factory has the expertise to produce Gold Ore Processing Plant products of the highest quality.

Our company has carried out long-term technical cooperation with well-known universities and scientific research institutions, so the product research and development capabilities are at the leading level in China. Our Mini Gold Wash Plant is sold in various industries and is very popular in Australia, Russia, Brazil, and other countries.

Our team of engineers works closely with our customers to tailor our Gold Ore Processing Plant products to their specific requirements.

In the future, we will continue to adhere to the strategy of going out, strengthen cooperation and ecological win-win development.

We offer a complete range of Gold Ore Processing Plant products to meet the needs of our customers.

We believe that every process penetrates into our persistent pursuit of quality; every design incorporates our care for customers; every innovation reflects our forward-looking thinking for the future.

We use only the best materials and components to produce our Gold Ore Processing Plant products.

Our company will meet the development needs of the digital economy era, focus on the Mini Gold Wash Plant industry, take reform and innovation as the fundamental driving force, base itself on the new development stage, implement new development concepts, and build a new development pattern.

Our team of professionals has extensive experience in the development and production of Gold Ore Processing Plant products.

We hope to drive the development of the industry with scientific and technological innovation, and help national brands to the world.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Gravity beneficiation process for iron ore

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Nickel ore priority flotation process(Sulfide ore)

- Lithium ore combined beneficiation process

- Radioactive beneficiation and flotation process for uranium ore

- chrome ore processing:Advanced Magnetic Separation Processing Technology

- Complete Manganese Ore Gravity Separation Process

Leave a message with your needs or comments

Add comment: