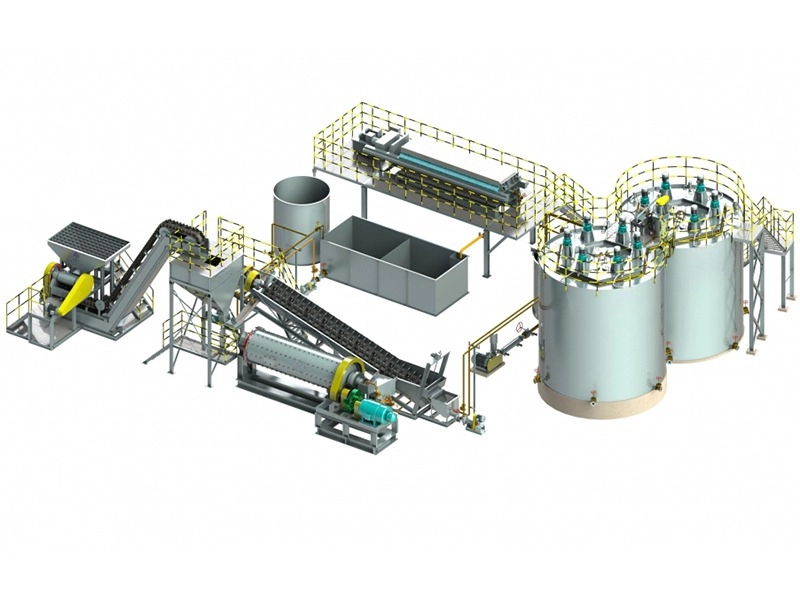

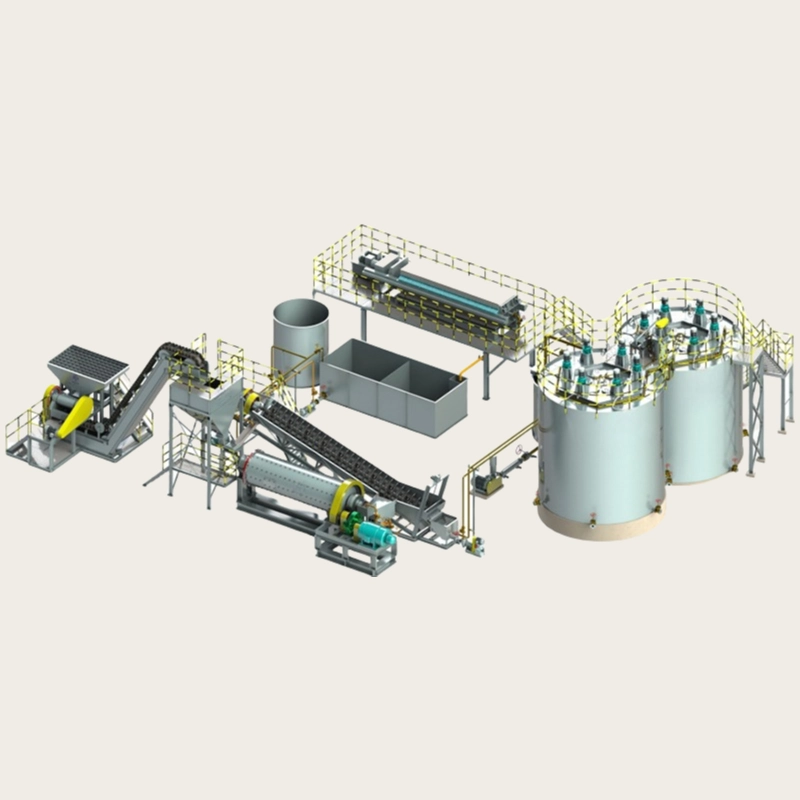

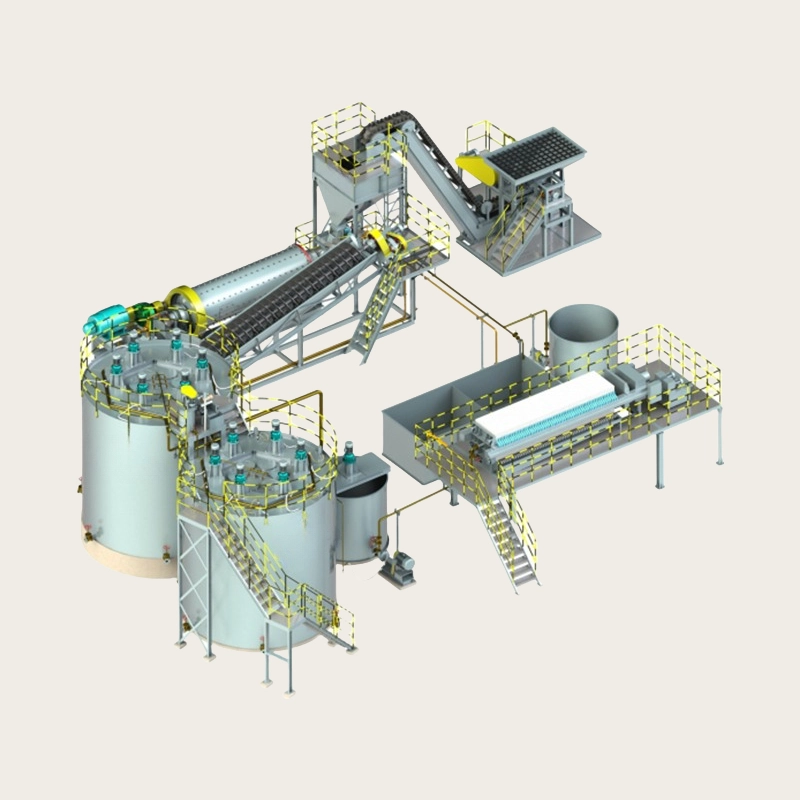

This relocatable plant can be used to process sulfide ore, oxidized ore, alluvial ore and tailings of certain grade to recover gold.

Functional module

According to the actual situation of materials and the demands of clients, the crushing module, grinding and classification module, gravity concentration module, pre-leaching concentration module, preprocessing module, leaching and absorption module, air flow, water and power supply module, tailings dewatering module and desorbing and electrolysis system can be freely selected and combined as a complete plant to maximize gold recovery.

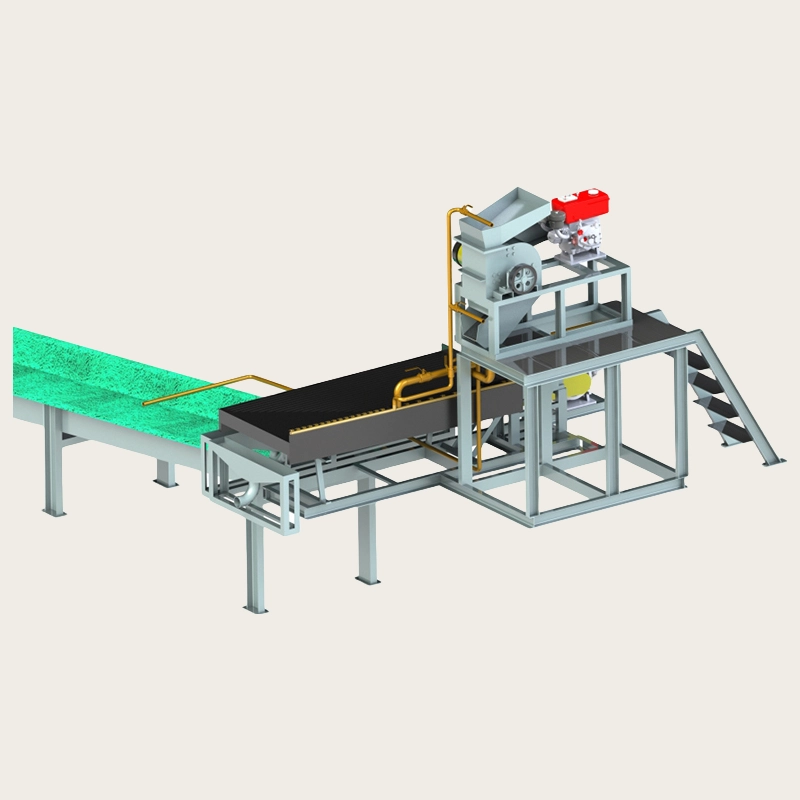

Crushing module

Rocks are crushed to the particle size suitable for grinding and the module consists of composed of hopper, crusher, belt conveyor, ore feeder.

The crushing of ore is usually two-stage. The first crusher can be placed in the mining area ( driven by a diesel engine) or the processing plant.

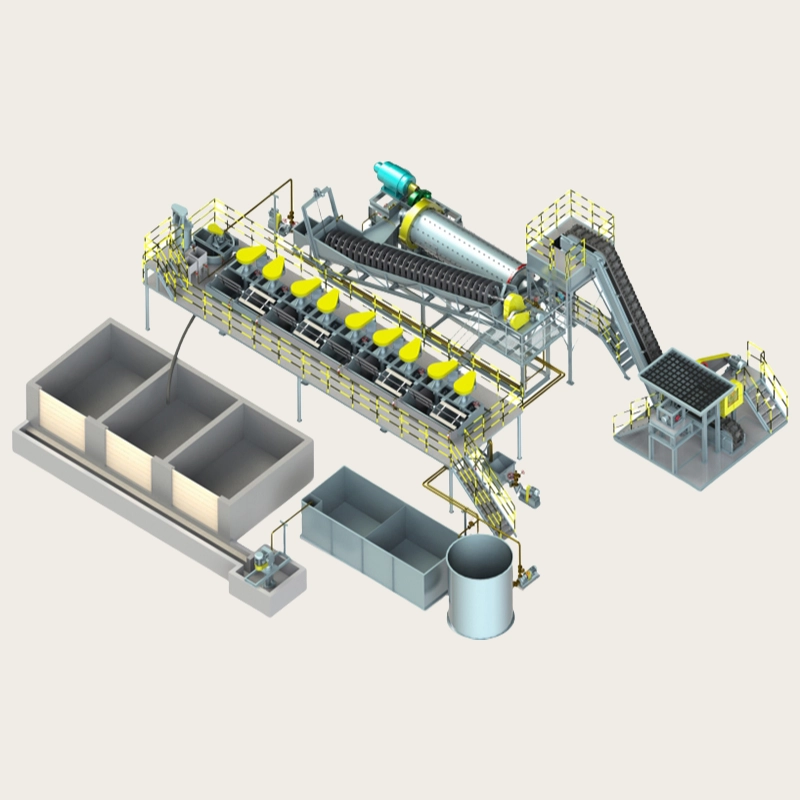

Grinding and classification unit

The closed-circuit grinding and classification system consisting of the ball mill and spiral classifier can dissociate ore into particles suitable for recovery. The module can be adjusted to a closed-circuit system consisting of the ball mill, slurry pump and hydrocyclone according to customers' needs.

The grinding and classification unit is completely set on a steel frame.

Water supply module

The water supply module is composed of the water tank, water pump and water supply pipeline. This module can fully control the use ratio of water, achieving ideal water balance.

Power supply module

It is composed of the diesel generator, the electrical distribution device and the electrical starter panel, which is suitable for areas that are hard to get to and has difficulties in power supply.

Note:

When coarse ores contain certain amount of gold particles, gravity concentration module is the recommended recovery method. Jigs are typically added to the grinding and classification circuit to recover coarse gold particles and the new coarse concentrates produced by jigs are sent to shaking table to be finely screened.

If the slurry concentration is relatively low after grinding and classification, pre-leaching concentration module needs to be adopted to improve slurry concentration to meet leaching and absorption demands.

If coarse ores contain sufficient amount of copper-oxide ore, arsenic and carbon nanoparticles and other toxic substances, preprocessing module should be adopted to eliminate toxic substances' impact on leaching and improve gold recovery rate.

It is strongly recommended to choose tailings dewatering module to reduce water and cyanide consumption and also to protect environment.

Clients can determine themselves whether or not to adopt the elution and electrowinning system. In order to save investment or extend the service life of the plant, gold-loaded carbon can be incinerated.

Special module

Pre-leaching concentration module

If the grinding and classification module is composed of ball mill and hydrocyclone, the slurry concentration is comparatively low after classification and it needs to be improved to 40-45% before leaching.

Preleaching concentration module is composed of thickener and flocculating agent feeder.

Feeding flocculant is to decrease thickener's sedimentation area and shorten sedimentation time so as to reduce investment on equipments and improve concentration efficiency.

Leaching and absorption module

Vibratory cleaning screen is installed to clean sawdust and fibrous materials which can easily absorb gold.

Leaching and absorption operation is completed in the integrated HZTank designed with special technology. According to specific ore type, the prodcution line can be assembled by different numbers of HZtank, which ensures the successful application of CIP and CIL techniques and the required leaching and absorption time.

HZTank, a cylinder, is divided into six individual leaching areas with each one possessing completely individual mixing and air flow supply device. Slurry self-flows to next leaching area and forms a continous process which is convenient for management and operation.

Bubbles in the tank are well dispersed because of the unique airflow supply equipment in HZTank which make the best use of oxygen by having oxygen fully participate in chemical reaction. Thus the tank is becoming less dependent on outside airflow. Inner airflow supply equipment can promote the mixing of slurry so as to reduce the input power of the agitator and save energy.

When HZtank is applied in absorption phase, carbon screen is installed between two adjacent leaching cell to ensure that the activated carbon can ba preserved in each leaching cell. The reversed movement of activated carbon is dby the air lifter, which makes sure that the activated carbon particles are well-preserved and thus saving energy consumption.

Air flow supply module

This module, composed of draught fan and pipeline system, is mainly responsible for providing oxygen for leaching reaction and power for the delivery of activated carbon.

Tailings dewatering module

Tailings after leaching are transferred to automatic filter press by slurry pump to be dewatered and the filter cakes after that process will be transported and piled outside the plant. The water and the reagent residuals can recycled. This processing method is not only beneficial for the environment and curtails investment on tailings reservoir, but also reduces water and reagents consumption.

Specifications

| Model Parameter | HZCIL-1 | HZCIL-2 | HZCIL-3 |

| Capacity(t/h) | 1 | 2 | 3 |

| Inlet sizeD80 (mm) | 18 | 18 | 18 |

| Grinding Size (mesh) | 200 | 200 | 200 |

| Ambient Temperature (℃) | -15~45 | -15~45 | -15~45 |

| Comprehensive Gold Recovery (%) | 85~95 | 85~95 | 85~95 |

| Single HZTank Leaching Time(h) | 12.6 | 12.8 | 12.7 |

| Water Content of Tailings Filter Cake (%) | < 15 | < 15 | < 15 |

| Onsite Installation Period (day) | 7 | 7 | 10 |

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Iron Ore Combined Beneficiation Process

- Gravity combined beneficiation process for black and white tungsten ore

- Zirconium Ore Separation: Gravity and Magnetic Methods

- Titanium Ore Processing: Magnetic Separation and Flotation

- Titanium Ore Processing: Gravity, Magnetic, Flotation, Electric Separation

- Tantalum-Niobium Ore Gravity Separation Methods

- Tantalum-Niobium Ore Processing: Gravity, Magnetic, and Electric Separation

Leave a message with your needs or comments

Add comment: