Myanmar Tuxingsun United Mining Mineral Research and Testing Center, as a leading mineral analysis and testing organization in the industry, has always been committed to providing accurate, efficient and professional ore element testing and testing services to mining customers. With advanced testing equipment, professional technical team, rich project experience and perfect quality management system, the center provides mining companies, mineral processing plants, ore buyers and ore terminals and other customers who need services with a full range of ore testing solutions from ore exploration to product sales, helping customers to maximize the value of mineral resources. Provide scientific basis for customers' mineral exploration, development and utilization.

Price is negotiable, large quantity discount!

Mandalay Sample Collection Office: 65-66-41

Contact Aliang-09796669988

Yangon Sample Collection Office: FG-12 Mowowasu Road/FMI Villa Area/Hlaing Tharyar/Yangon

Contact Agui-09259439704

Advantages of the Center

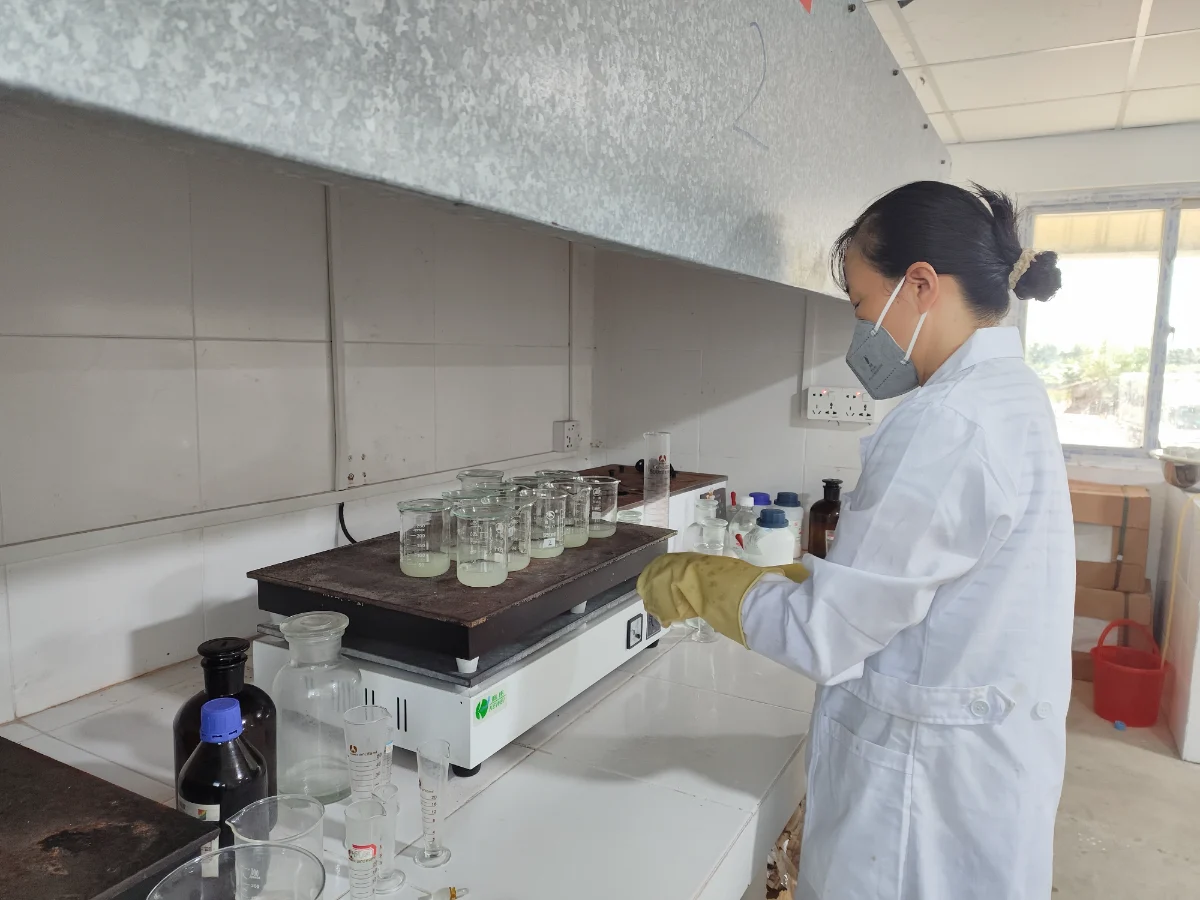

Advanced testing equipment: We are equipped with world-class ore analysis instruments, including WFX-220B atomic absorption spectrophotometer (AAS), VIS-723N spectrophotometer, Eupu Lab ultrapure water machine and other advanced equipment, which can quickly and accurately perform quantitative analysis of trace elements and major elements in ores.

Professional team: The center has an experienced technical team, all members of which have many years of experience in mineral analysis and can provide customers with professional technical consultation and services.

![Tuxingsun United Mining Mineral Research and Testing Center Ore Element Laboratory ore testing mineral processing lab laboratory analysis metallurgical beneficiation services gold copper rare earth composition mining chemical grade 第2张 Tuxingsun United Mining Mineral Research and Testing Center Ore Element Laboratory ore testing mineral processing lab laboratory analysis metallurgical beneficiation services gold copper rare earth composition mining chemical grade 第2张]()

Comprehensive testing items: Our services cover ore elements: gold, silver, copper, lead, zinc, lithium, molybdenum, antimony, bismuth, tungsten, tin, including but not limited to mineral composition and harmful element detection and analysis, ore dressing test and sample leaching test. We can provide targeted testing services according to customer needs and solve practical problems for customers.

Fast testing cycle: The center has established an efficient testing process and can provide customers with test reports within 24-72 hours.

Strict quality control: The center has established a complete quality assurance system and conducts testing in accordance with the latest national standard of the People's Republic of China GB/T2019 to ensure the accuracy and reliability of the test results.

Efficient service: A complete service system has been established to ensure short testing cycles and timely report issuance.

Customized service: Provide personalized testing solutions according to customer needs.

![Tuxingsun United Mining Mineral Research and Testing Center Ore Element Laboratory ore testing mineral processing lab laboratory analysis metallurgical beneficiation services gold copper rare earth composition mining chemical grade 第3张 Tuxingsun United Mining Mineral Research and Testing Center Ore Element Laboratory ore testing mineral processing lab laboratory analysis metallurgical beneficiation services gold copper rare earth composition mining chemical grade 第3张]()

Service scope

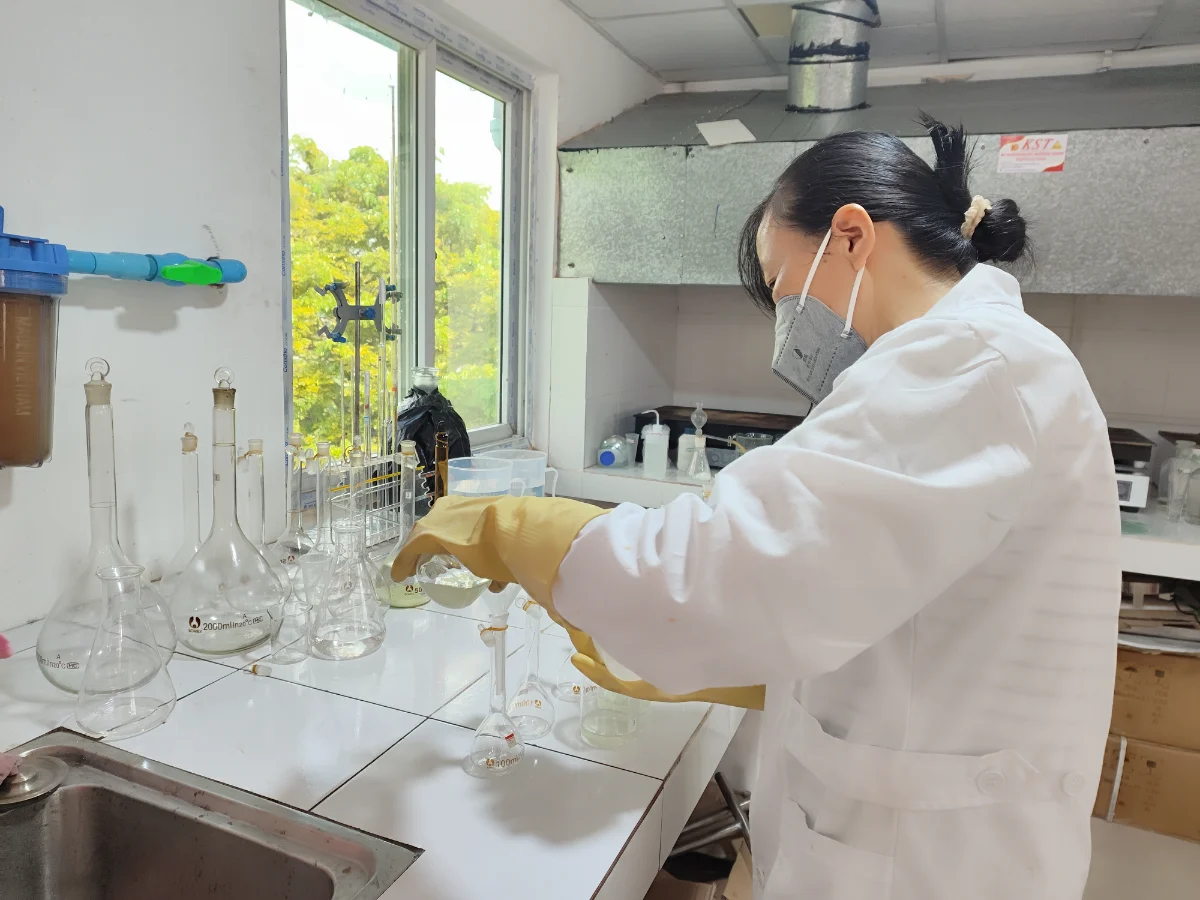

Conventional element analysis: Quantitative analysis of the main common elements in ores: gold, silver, copper, lead, zinc, lithium, molybdenum, antimony, bismuth, tungsten, tin and other minerals to provide a basis for ore grade evaluation.

Ore dressing test and sample leaching test, field design, dressing process design

We can carry out new element detection services according to the needs of long-term cooperative customers and solve practical problems for customers.

![Tuxingsun United Mining Mineral Research and Testing Center Ore Element Laboratory ore testing mineral processing lab laboratory analysis metallurgical beneficiation services gold copper rare earth composition mining chemical grade 第4张 Tuxingsun United Mining Mineral Research and Testing Center Ore Element Laboratory ore testing mineral processing lab laboratory analysis metallurgical beneficiation services gold copper rare earth composition mining chemical grade 第4张]()

Testing items

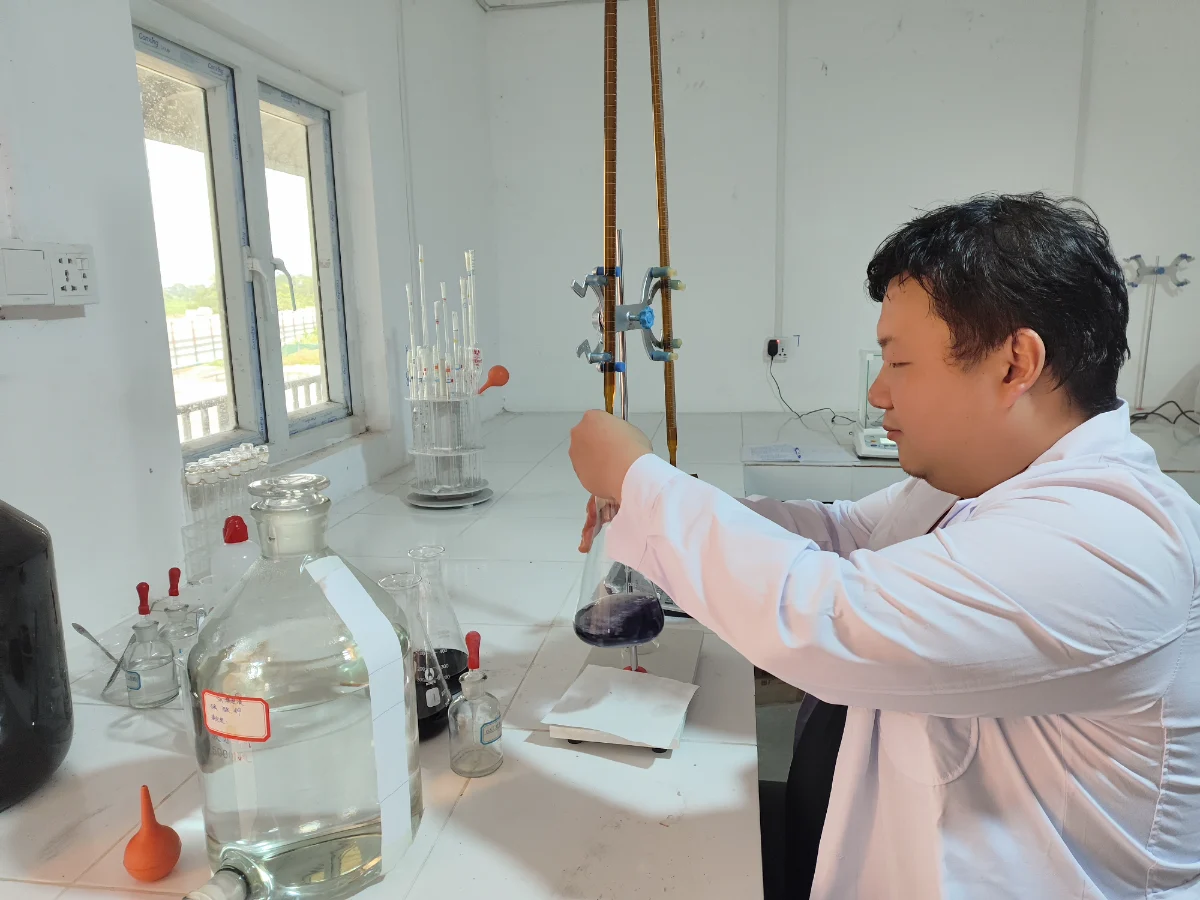

Element analysis: quantitative and qualitative analysis of major elements and trace elements.

Mineral identification: identification of mineral types, determination of mineral content, etc.

Chemical composition analysis: quantitative analysis of chemical composition, purity analysis, etc.

![Tuxingsun United Mining Mineral Research and Testing Center Ore Element Laboratory ore testing mineral processing lab laboratory analysis metallurgical beneficiation services gold copper rare earth composition mining chemical grade 第5张 Tuxingsun United Mining Mineral Research and Testing Center Ore Element Laboratory ore testing mineral processing lab laboratory analysis metallurgical beneficiation services gold copper rare earth composition mining chemical grade 第5张]()

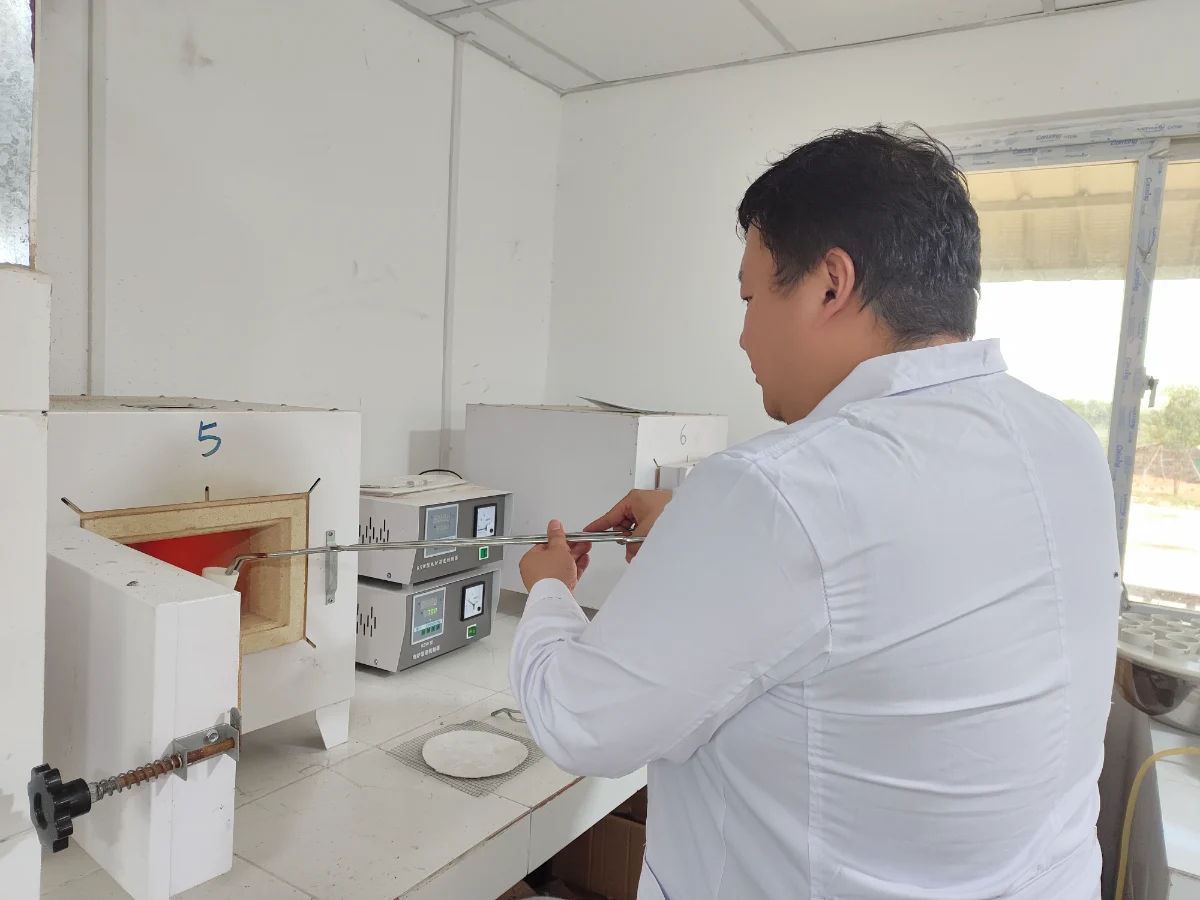

Testing process

1. Sample collection: The customer delivers the sample to the sample receiving point and fills in the sample information form.

2. Sample registration: The laboratory registers the sample and assigns a unique identification code.

3. Sample baking: Put the sample into the oven and bake it at low temperature for 2 hours.

4. Sample pretreatment: The sample is pretreated by crushing, fine grinding, sieving, weighing, etc.

5. Sample analysis: The pretreated sample is analyzed by personnel operation.

6. Data processing: Process and analyze the generated data.

7. Report review: Review the test report to ensure the accuracy of the data.

8. Report issuance: Issue test report and test results.

Quality Assurance

Standardized management: The test center has established a complete quality management system and conducts tests in strict accordance with national and industry standards.

Instrument calibration: Regularly calibrate the test instruments to ensure the accuracy of the instruments.

Personnel training: Regularly train technical personnel to improve their professional level.

Data review: Strictly review the test data to ensure the accuracy of the results.

![Tuxingsun United Mining Mineral Research and Testing Center Ore Element Laboratory ore testing mineral processing lab laboratory analysis metallurgical beneficiation services gold copper rare earth composition mining chemical grade 第7张 Tuxingsun United Mining Mineral Research and Testing Center Ore Element Laboratory ore testing mineral processing lab laboratory analysis metallurgical beneficiation services gold copper rare earth composition mining chemical grade 第7张]()

Our commitment

Scientific and rigorous: Strictly conduct tests in accordance with standards and industry specifications to ensure the accuracy and reliability of the test results.

Service first: Guided by customer needs, provide efficient and professional testing services.

Technological innovation: Continuously introduce advanced testing technologies and equipment to improve the level of testing.

Data confidentiality: Strictly protect customers' test data and ensure commercial secrets.

Choosing us means choosing professional, efficient and reliable testing services!

- Random article

- Popular articles

- Popular comments

- Gold Mine Heap Leaching: Optimal Process

- Sand gold beneficiation process

- Scheelite Flotation Method

- Nickel ore priority flotation process(Sulfide ore)

- chrome ore processing:Advanced Magnetic Separation Processing Technology

- Chromite Gravity and Magnetic Separation Process

- Chromite Processing: Gravity, Magnetic, and Flotation Separation

Leave a message with your needs or comments

Add comment: