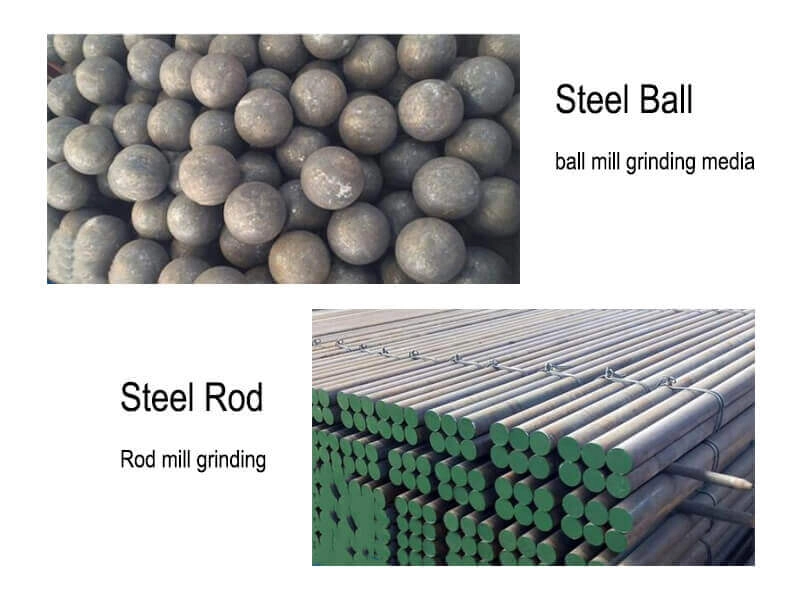

When it comes to grinding materials in the mining and construction industries, ball mills and rod mills are essential pieces of equipment. These machines are used to grind various materials into fine powders, and the choice of grinding media plays a vital role in their performance. The most common types of grinding media found in ball and rod mills are rigid balls and steel rods. In this guide, we’ll explore the differences between ball mills and rod mills, and how to choose the right grinding media for the best results.

Ball mills and rod mills are both used to grind materials, but they operate in different ways. Ball mills use a cylindrical vessel that rotates around its axis, while rod mills use long steel rods as the grinding media. The choice between the two depends on the type of material being ground and the desired particle size. In terms of grinding media, ball mills typically use rigid balls, while rod mills use steel rods. Rigid balls are usually made of steel or other hard materials and are designed to crush and grind materials inside the mill. Steel rods, on the other hand, grind material by stacking and rolling inside the mill, resulting in a more even and finer grind.

Choosing the right grinding media for ball and rod mills is critical to achieving the desired results. Rigid balls are ideal for grinding materials that need to be broken and crushed, such as ores, cement and chemicals. Steel rods, on the other hand, are better suited for grinding materials that require a finer and more uniform grind, such as sand, gravel, and other aggregates. When selecting grinding media, factors such as material hardness, density, and abrasiveness should be considered. Additionally, the size and shape of the grinding media can also affect the grinding process. For example, larger balls or rods can break down large particles more efficiently, while smaller media can perform better at finer grinding. In conclusion, understanding the differences between ball mills and rod mills and the characteristics of different grinding media is critical to selecting the correct equipment and achieving optimal grinding results in various industrial applications.

ball mills and rod mills are essential equipment for grinding materials in various industries. The choice of grinding media, whether rigid balls or steel rods, plays a vital role in the performance of these machines. Understanding the differences between ball mills and rod mills and the characteristics of different grinding media is critical to obtaining optimal results. By considering factors such as material type, desired particle size, and grinding efficiency, one can select the appropriate equipment and grinding media for their specific application. Whether crushing ore in a mining operation or grinding aggregates in a construction project, the right combination of ball mills, rod mills and grinding media is key to achieving the desired results.

- Random article

- Popular articles

- Popular comments

- Gold Ore Thiourea Beneficiation

- Lead-zinc Ore Asynchronous Flotation Process

- Laterite Nickel Ore Hydrometallurgical Process for Oxide Ore

- Lithium ore reverse flotation process

- Chromium Ore Gravity Separation and Flotation Process

- Manganese Ore Separation: Gravity and Magnetic Methods

- Molybdenite Grinding and Separation Process

Leave a message with your needs or comments

Add comment: