The Full Lime Cyanide Project of Luang Prabang Gold Mine in Laos is a significant development in the mining industry, particularly in the extraction of valuable elements such as gold. With a gold content of 9 grams per ton and an inorganic carbon content of 10.94%, the project is poised to make a substantial impact. What sets this project apart is its commitment to environmentally friendly practices, including the use of the Jinchan environmentally friendly gold leaching agent as a substitute for sodium cyanide. This innovative approach not only ensures the efficient extraction of gold but also minimizes the environmental impact of the mining process.

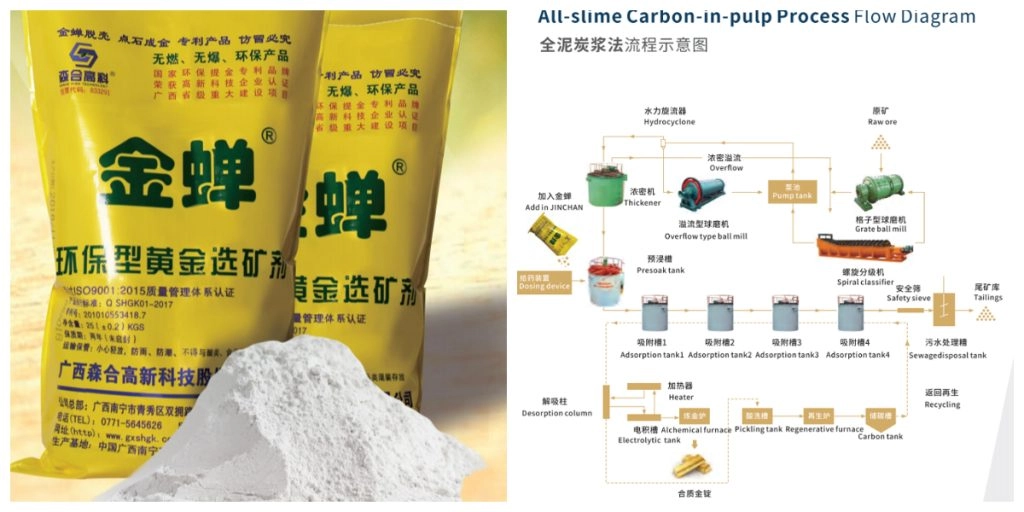

One of the key factors contributing to the success of the Full Lime Cyanide Project is the utilization of the Jinchan environmentally friendly gold leaching agent. This agent has been specifically designed to facilitate the leaching and absorption process in a sustainable manner. With a four-stage leaching and five-stage absorption process, the Jinchan agent ensures that the gold leaching effect remains unaffected, even with the presence of inorganic carbon content. This is a significant breakthrough in the industry, as it demonstrates that environmentally friendly alternatives can be just as effective as traditional methods. By embracing this approach, the Luang Prabang Gold Mine is setting a new standard for responsible and sustainable mining practices.

the substitution of sodium cyanide with the Jinchan environmentally friendly gold leaching agent is a testament to the mine’s commitment to environmental stewardship. Sodium cyanide has long been the industry standard for gold leaching, but its toxic nature poses significant risks to the environment and human health. In contrast, the Jinchan agent offers a safer and more sustainable alternative, ensuring that the gold extraction process does not come at the expense of environmental degradation. This shift towards environmentally friendly practices not only benefits the local ecosystem but also sets a positive example for the wider mining industry.

When the grinding fineness is -0.074mm and the content is greater than 90%, the slurry concentration is 40%, the lime dosage is 3kg/t, the alkali pre-treatment time is 2 hours, and the Jinchan environmental protection gold extraction agent dosage is 600g/t, the leaching time is 24 hours, the gold leaching rate can reach 96.40%. Compared with cyanide leaching, the leaching rate is increased by 1.4%, and the reagent dosage is reduced by 200g/ton, and the leaching time is shortened by more than 12 hours. In addition, a leaching toxicity analysis of the Jinchan environmental protection gold extraction agent leaching residue was conducted. The results show that the leaching toxicity values of cyanide, copper, lead, zinc, and arsenic in the tailings are all within the national standard limits. It can be drained directly without detoxification treatment.

Compared with the cyanide leaching process, the leaching rate can be increased by 1.4%, the reagent consumption is reduced by 200 grams per ton, and the leaching time is shortened by more than 12 hours, achieving good leaching results and significant economic benefits.

the Full Lime Cyanide Project of Luang Prabang Gold Mine in Laos represents a significant milestone in the mining industry. With its focus on environmentally friendly practices and the use of innovative technologies such as the Jinchan environmentally friendly gold leaching agent, the project is leading the way towards a more sustainable and responsible approach to gold extraction. By demonstrating that valuable elements like gold can be extracted efficiently without compromising the environment, the Luang Prabang Gold Mine is setting a new standard for the industry. This project serves as a testament to the fact that responsible mining practices and environmental stewardship can go hand in hand, paving the way for a more sustainable future in the mining sector.

- Random article

- Popular articles

- Popular comments

- Stepwise priority flotation process for copper ore

- Intense Magnetic Separation Process for Iron Ore

- Prioritized Flotation Process for Lead-zinc Ore

- Lead-zinc Ore Asynchronous Flotation Process

- Radioactive beneficiation and flotation process for uranium ore

- Titanium Ore Processing: Magnetic Separation, Gravity Separation, Flotation

- Rutile Gravity Separation, Magnetic Separation, and Flotation Process

Leave a message with your needs or comments

Add comment: