Screening equipment is widely applied in industrial sectors of metallurgy, building material, coal, and road construction. The screen panels and sieves of a screening equipment can separate mixed material of different kinds into different classes of particle sizes through the combination of single-deck or multi-deck screens, so as to meet the requirements of a certain ore dressing process.

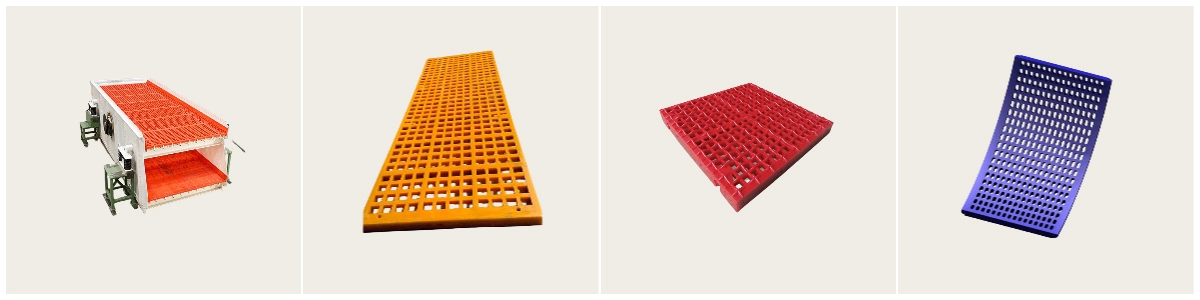

Vibrating screen panel

Screening equipment is widely applied in industrial sectors of metallurgy, building material,coal, and road construction.

The screen panels and sieves of a screening equipment can separate mixed material of different kinds into different classes of particle sizes through the combination of single-deck or multi-deck screens, so as to meet the requirements of a certain ore dressing process.

Our vibrating screen panel which has outstanding qualities and will significantly increase panel life in both high impact and high abrasion applications.

Specifications

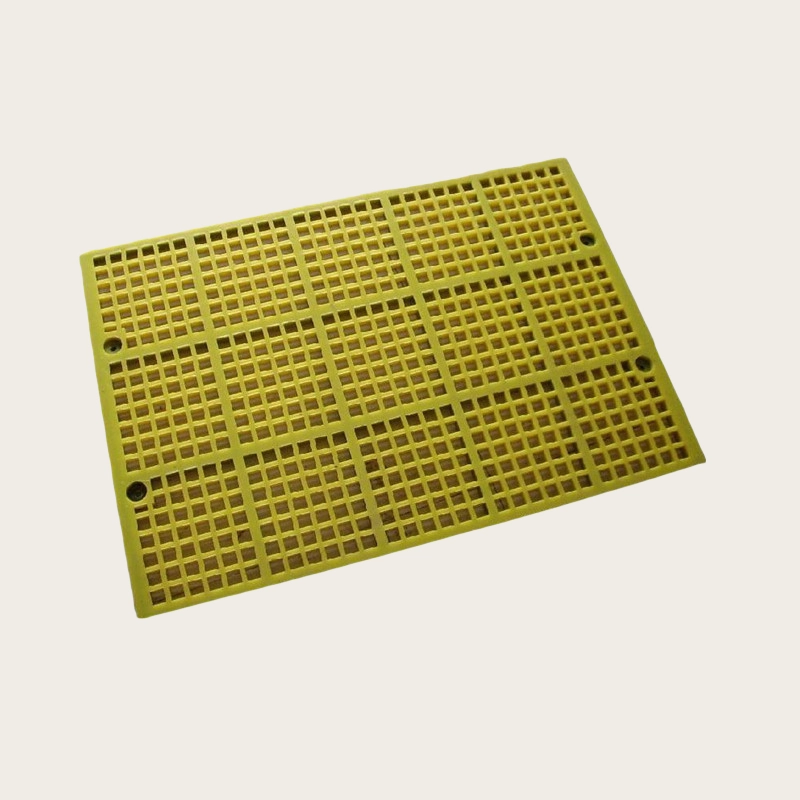

1.High abrasion resistant

2.Corrosion-resistance, non-toxic

3.Self-cleaning effect

4.High performance of Moisture resistan

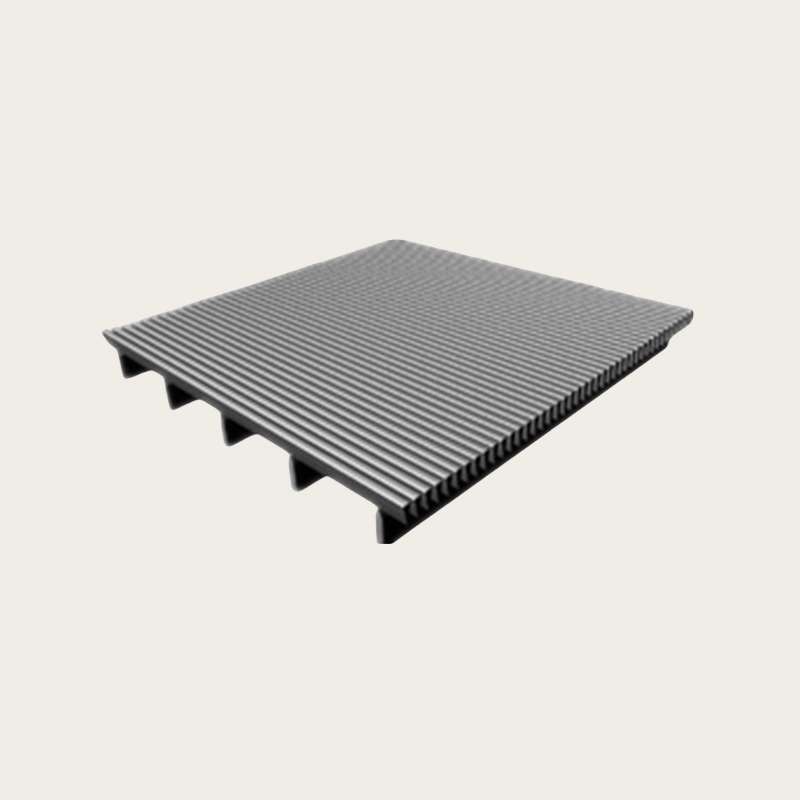

I. Features of vibration screen panel

Light in weight, easy for strip-down and reassembly on site, reducing operators’ work intensity; High damping capacity resulting in reduced noise; Good resilience leading to a higher bounce frequency of materials and an increased screen efficiency; Apertures remain unblocked; Thanks to the wear resistance of rubber material, screen apertures keep a constant size, resulting in a screening accuracy over the range of 90%.

II. Advanced Manufacture Technology of vibration screen panel

Cutting and bonding technology: screen panels are processed with cutting and bonding technologies, where a cut-out panel can be bonded with a clamping bar, an end plate or a hook plate with the bonding technology.

Flexible skeleton: screen apertures are surrounded by flexible skeletons, making them free of blockage.

III. Structural Form of vibration screen panel

Structure with hooking: in order to facilitate the installation and to increase the tension strength, rubber panels are individually compression molded, then clamping strips, clamping edges and hook plates can be mounted by means of bonding or riveting.

Structure with bolting: metal skeletons are inserted in rubber panels to prepare mounting bolt holes, which are fastened on screen frame with bolts.

We can provide customized design according to our clients’ demands and also refine our products by our clients’ feedback.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Gold selection process using resin slurry method

- Branch serial flow flotation process for lead-zinc ore

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Lithium ore magnetic separation process

- Lithium Ore Processing: Gravity Separation and Flotation

- Radioactive beneficiation and flotation process for uranium ore

Leave a message with your needs or comments

Add comment: